An experimental device and method for studying the combustion characteristics of pulverized coal particles in a turbulent flow field

A technology of combustion characteristics and experimental equipment, which is applied in the field of pulverized coal combustion, can solve problems such as difficult adjustment, lack of turbulent influence, and restrictions, and achieve the effects of simplified parameter adjustment, uniform distribution of temperature and components in the field, and uniform distribution of the flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

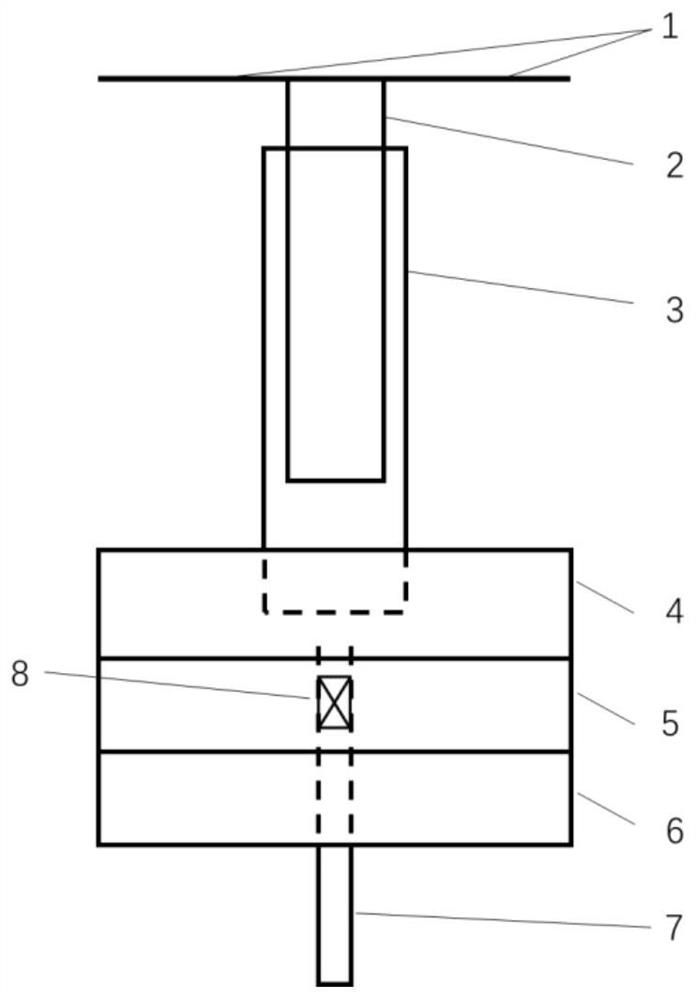

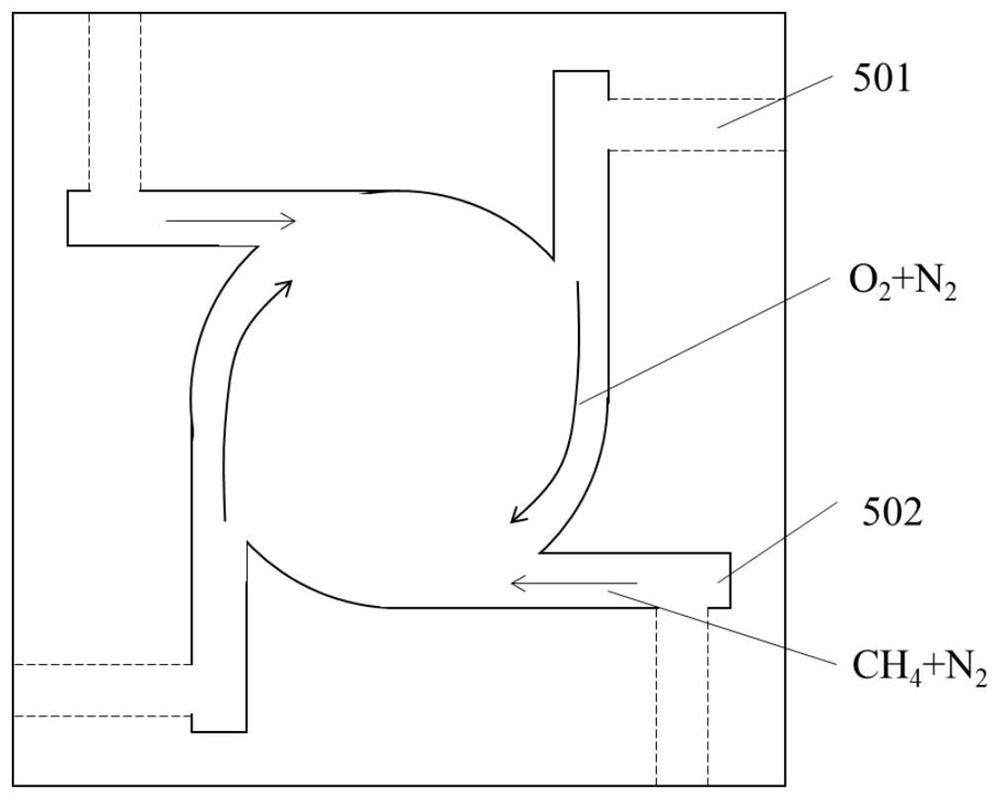

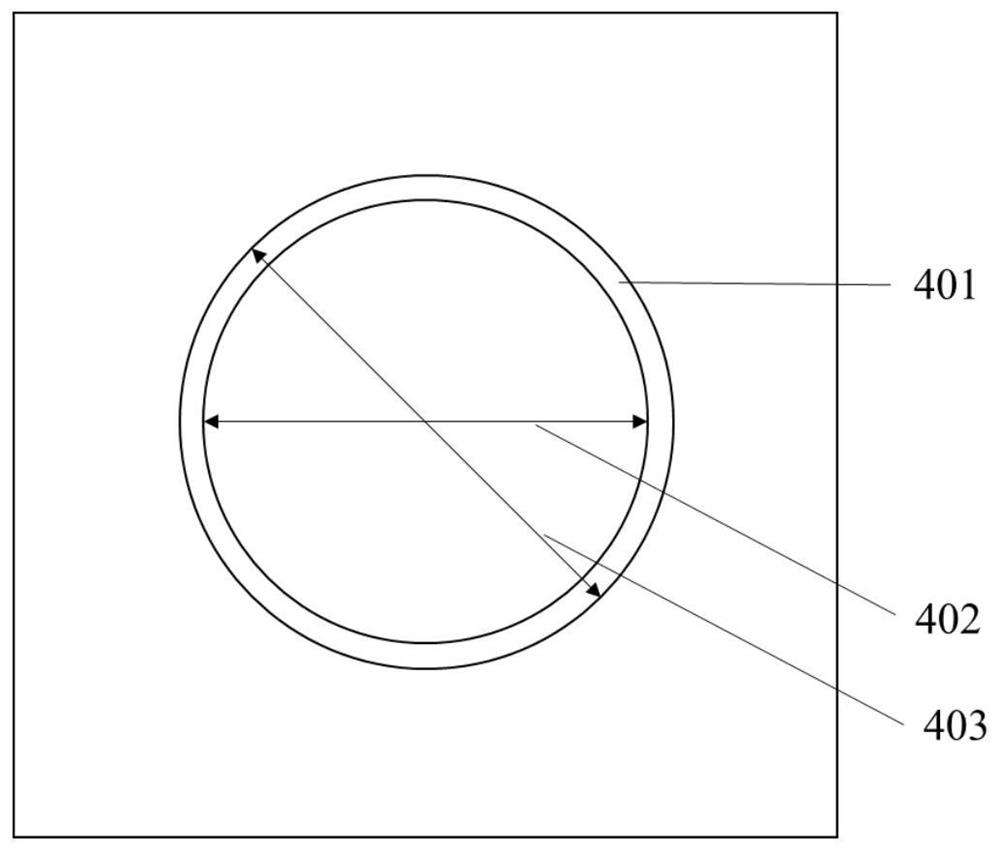

[0037] like figure 1 , the experimental device for studying the combustion characteristics of pulverized coal particles in the turbulent flow field of the present invention includes a bracket 1, an inner quartz tube 2, an outer quartz tube 3, an upper cover plate 4, a middle plate 5, a lower cover plate 6 and a central powder feeding tube 7 .

[0038] The bracket 1 mainly includes the bottom part for carrying the lower cover plate 6 and the base part for fixing the center powder feeding pipe 7 and the upper part for hanging and fixing the inner quartz tube 2. The cantilever clamp part is adjustable in the horizontal and height directions, which can be convenient The relative position of the inner quartz tube 2 in the outer quartz tube 3 is adjusted.

[0039] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com