Cover plate glass and preparation method thereof

A manufacturing method and cover glass technology, applied in the field of touch sensing, can solve the problems of increasing the overall thickness of the Coverlens, affecting the visibility of the Coverlens, reducing the transmittance, etc., so as to avoid the influence of the glass transmittance, high engraving and etching accuracy, the effect of optimizing densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

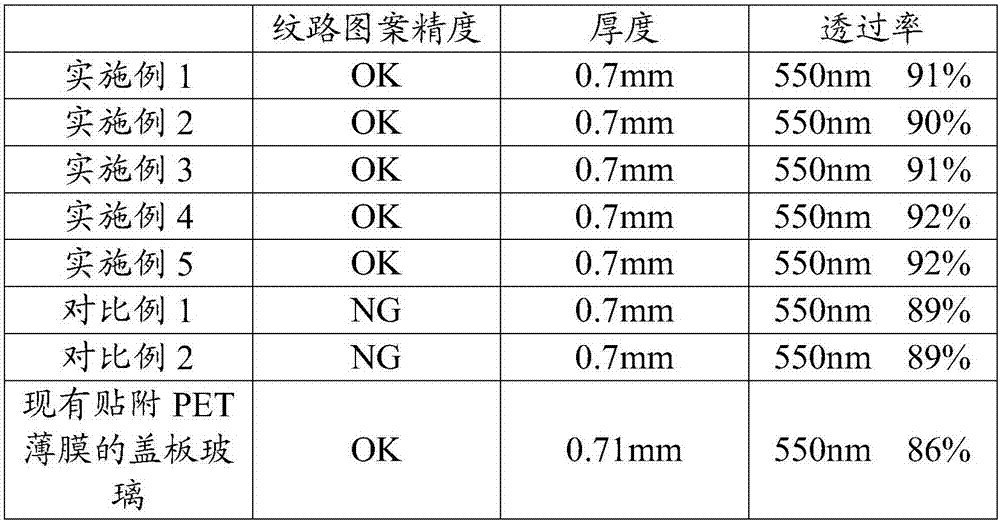

Examples

Embodiment 1

[0035] A method for manufacturing a cover glass in this embodiment comprises the following steps:

[0036] Step 1: Cut the large piece of glass raw material into small pieces of glass to obtain a glass substrate, and the glass substrate is provided with a texture pattern area;

[0037] Step 2: Deposit a metallic silver layer on one side of the glass substrate with a thickness of 110nm; the metallic silver layer is provided with a window area corresponding to the texture pattern area; wherein, the deposition process is as follows: using PVD Coating equipment electroplating metal silver layer, vacuum chamber pressure: 3×10 -5 Pa; silver arc target current: 150~180A; bias voltage: 8000V;

[0038] Step 3: Make the texture pattern to be processed into an electronic graphic file (such as CAD, Corldraw, Pro / E, etc.), and import it into the software connected to the laser engraving machine, and convert it into a laser engraving program;

[0039] Step 4: Debug the laser engraving mac...

Embodiment 2

[0045] A method for manufacturing a cover glass in this embodiment comprises the following steps:

[0046] Step 1: Cut the large piece of glass raw material into small pieces of glass to obtain a glass substrate, and the glass substrate is provided with a texture pattern area;

[0047]Step 2: Deposit a metallic silver layer on one side of the glass substrate, with a thickness of 30nm; the metallic silver layer is provided with a window area corresponding to the texture pattern area; wherein, the deposition process is as follows: using PVD Coating equipment electroplating metal silver layer, vacuum chamber pressure: 5×10 -5 Pa; silver arc target current: 150~180A; bias voltage: 8000V;

[0048] Step 3: Make the texture pattern to be processed into an electronic graphic file (such as CAD, Corldraw, Pro / E, etc.), and import it into the software connected to the laser engraving machine, and convert it into a laser engraving program;

[0049] Step 4: Debug the laser engraving mach...

Embodiment 3

[0055] A method for manufacturing a cover glass in this embodiment comprises the following steps:

[0056] Step 1: Cut the large piece of glass raw material into small pieces of glass to obtain a glass substrate, and the glass substrate is provided with a texture pattern area;

[0057] Step 2: Deposit a metallic silver layer on one side of the glass substrate with a thickness of 105nm; the metallic silver layer is provided with a window area corresponding to the texture pattern area; wherein, the deposition process is as follows: using PVD Coating equipment electroplating metal silver layer, vacuum chamber pressure: 1×10 -5 Pa; silver arc target current: 150~180A; bias voltage: 7500V;

[0058] Step 3: Make the texture pattern to be processed into an electronic graphic file (such as CAD, Corldraw, Pro / E, etc.), and import it into the software connected to the laser engraving machine, and convert it into a laser engraving program;

[0059] Step 4: Debug the laser engraving mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com