Transparent double-sided adhesive sheet having polarized light eliminating function

A linear polarizing, adhesive sheet technology, applied in the direction of film/flake adhesive, adhesive type, nonlinear optics, etc. The effect of ensuring operability, reducing thickness, and ensuring image visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

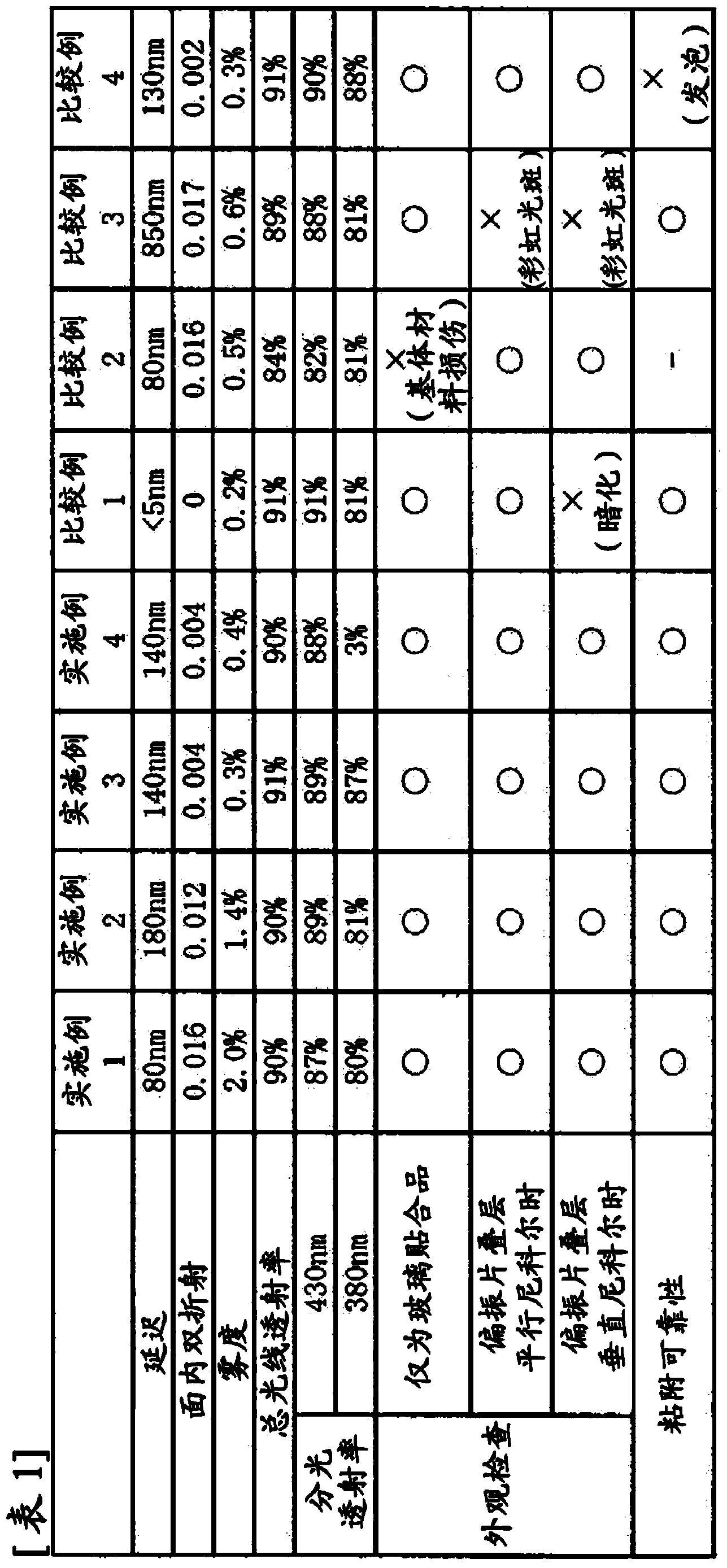

[0094] Hereinafter, the present invention will be described in more detail based on the following examples and comparative examples.

[0095]

[0096] As an adhesive composition for forming the first adhesive layer, 2.5 g of an epoxy curing agent solution (manufactured by Soken Chemical Co., Ltd., E-AX) was added to 1 kg of adhesive resin solution to prepare an adhesive. Composition 1, the adhesive resin solution is obtained by diluting the acrylate copolymer to a solid content of 25% with ethyl acetate, wherein the acrylate copolymer is 70 parts by mass of butyl acrylate, methacrylic acid 20 parts by mass of methyl ester, 9 parts by mass of methyl acrylate and 1 part by mass of acrylic acid were randomly copolymerized.

[0097] On the other hand, as an adhesive composition for forming the second adhesive layer, 5 g of pentaerythritol triacrylate as an ultraviolet crosslinking agent and 4-methanol as a photopolymerization initiator were added to 1 kg of the acrylate copolyme...

Embodiment 2

[0101] Except that a polyethylene terephthalate biaxially oriented film (manufactured by Teijin DuPont Film Co., Ltd., "Melinex #850", thickness 15 μm, in-plane birefringence 0.012) is used to form the linear polarization canceling layer 2 instead of the linear polarization canceling layer 1 Except, operate in the same manner as in Example 1, and make a double-sided adhesive sheet 2 composed of release film 1 / adhesive layer 1 / linear polarization canceling layer 2 / adhesive layer 2 / release film 2 for engineering [ Adhesive layer 1 (25 μm) / linear polarization canceling layer 2 (15 μm) / adhesive layer 2 (150 μm)=total thickness 190 μm].

Embodiment 3

[0103] In addition to using a polycarbonate uniaxially stretched film (manufactured by Kaneka Co., Ltd., "Elmec R40", thickness 40 μm, in-plane birefringence 0.004) to form the linear polarization canceling layer 3 instead of the linear polarization canceling layer 1, and make the adhesive Except that the thickness of layer 2 was 135 μm, the same operation as in Example 1 was carried out, and a double-layer film composed of engineering release film 1 / adhesive layer 1 / linear polarization canceling layer 3 / adhesive layer 2 / engineering release film 2 was produced. Surface adhesive sheet 3 [(adhesive layer 1 (25 μm) / linear polarization canceling layer 2 (40 μm) / adhesive layer 2 (135 μm)=total thickness 200 μm].

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com