Water purifier and method for protecting water pump by using water purifier

A water purifier and water pump technology, applied in chemical instruments and methods, separation methods, osmotic/dialysis water/sewage treatment, etc., can solve the problems of no idling protection of water pumps, harsh noises, etc., to prevent waterless idling and burning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

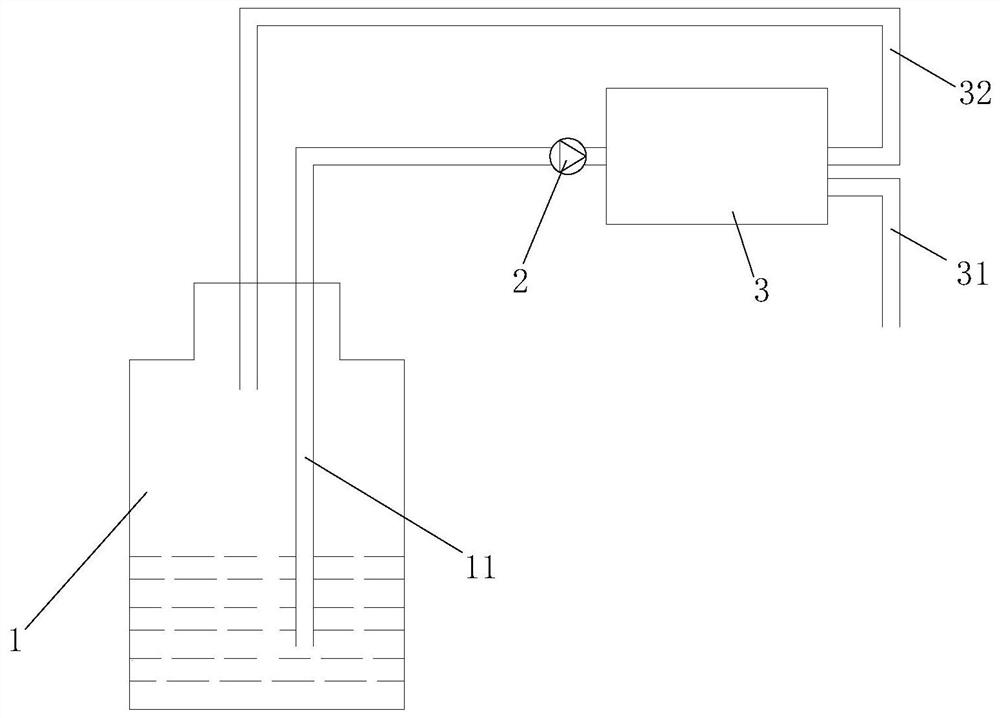

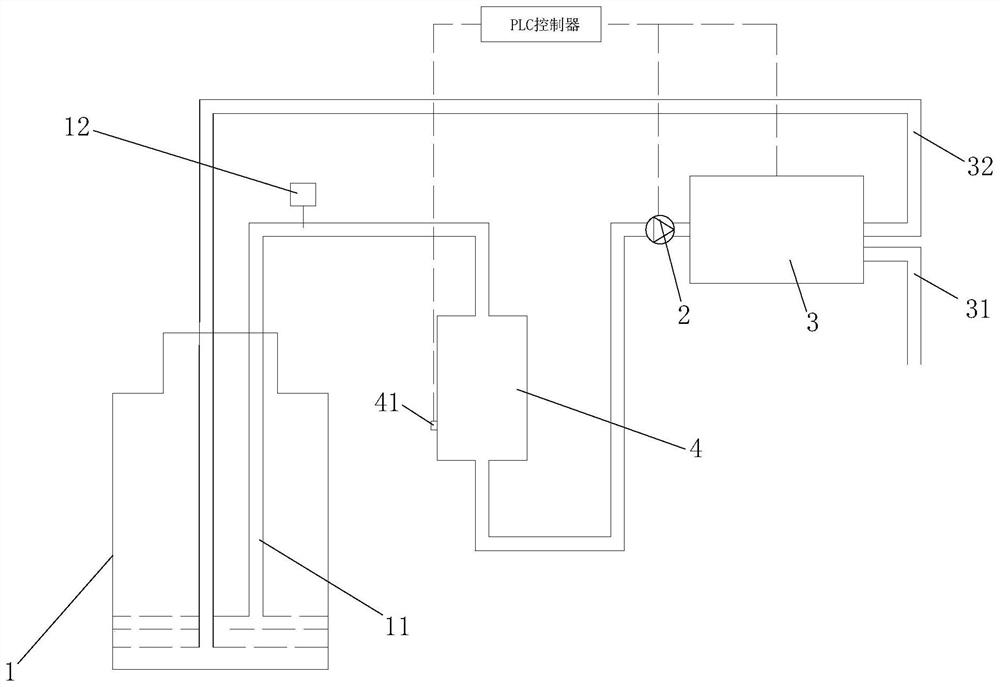

[0044] see figure 2 As shown, in order to solve the defects existing in the prior art, the present invention provides a water purifier, including a raw water bucket 1, a water pump 2, a filtration system 3 and a control assembly, and the raw water pipe 11 is equipped with a gas-water liquid The level control tank 4, the water pump 2 extracts the raw water in the raw water bucket 1 and collects it into the air-water level control tank 4, and then flows to the filter system 3 to filter, and the purified water is discharged through the clean water pipe 31, and the concentrated water is discharged through the return The water pipe 32 flows back to the raw water barrel 1, and a water level switch 41 is arranged on the outer wall of the tank 4 of the air-water level control tank 4. The control component is a PLC controller, and the PLC controller is respectively connected with the induction switch, the Said water pump 2, said filtering system 3 are controlled and connected;

[004...

Embodiment 2

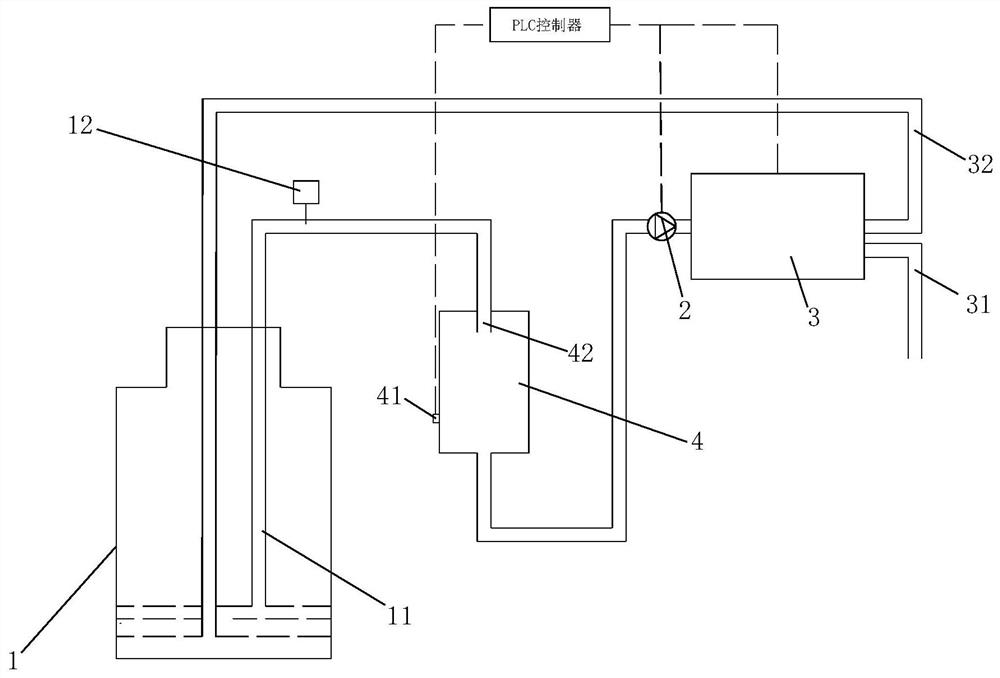

[0053] see image 3 As shown, the difference between this embodiment and Embodiment 1 is that the water inlet of the gas-water level control tank 4 extends to the inner cavity of the tank to form a water inlet pipe 42, and the raw water enters the gas-water level control tank 4 through the water inlet pipe 42. The inner cavity of the tube 4 allows the raw water to drop directly from the inlet pipe and splash on the liquid surface, so that the air in the tank is converted into small air bubbles and then mixed with the raw water to prevent the raw water from flowing down slowly along the inner wall of the tank. The pump 2 will The raw water mixed with small air bubbles is pumped to the filter system 3 for filtration.

Embodiment 3

[0055] see Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the water outlet of the air-water level control pipe 4 extends toward the inner cavity of the tank to form an outlet pipe 43, which is located at the end of the outlet pipe 43 in the inner cavity of the tank. The first water outlet 431 and the second water outlet 432 are respectively pierced on the water outlet pipe 43, and the water level switch 41 is located between the first water outlet 431 and the second water outlet 432;

[0056] The cross-sectional area of the first water outlet 431 and the second water outlet 432 are the same, the sum of the cross-sectional areas of the two water outlets is equal to the cross-sectional area of the water outlet pipe 43, and the cross-sectional area of a single water outlet is half of the cross-sectional area of the water outlet pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com