A method for beneficiation and separation of copper-zinc sulfide ore

A sulfide ore, copper-zinc technology, applied in solid separation, flotation, mechanical material recovery, etc., can solve the problems of high grinding cost, loss of metal resources, long process flow, etc., to reduce metal loss and improve overall economic benefits , cost reduction effect

Active Publication Date: 2022-06-03

HUNAN RES INST FOR NONFERROUS METALS

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

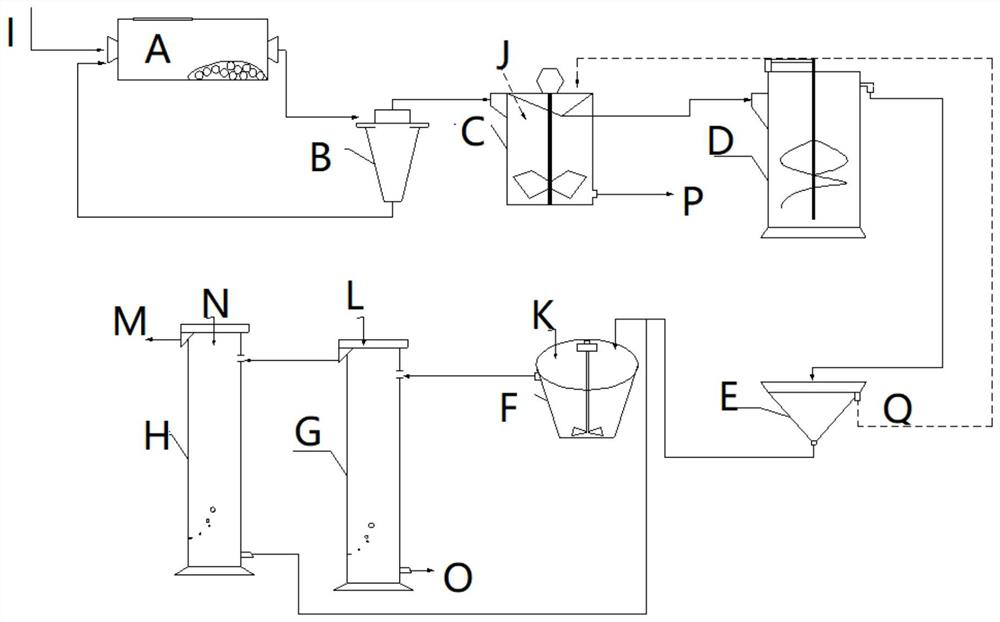

[0005] Aiming at the deficiencies of the prior art, the purpose of the present invention is to provide a method for beneficiation and separation of copper-zinc sulfide ore, which overcomes the serious loss of metal resources, long process flow, and grinding cost in the traditional copper-zinc separation process of using the copper-floating zinc suppression process. For high-level defects, the separation of copper-zinc sulfide ores is realized by using flotation columns to reselect different sulfide ores, and copper sulfate is used to increase the floating rate of sphalerite to achieve the purpose of floating zinc and suppressing copper, thereby improving the efficiency of copper-zinc beneficiation and separation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

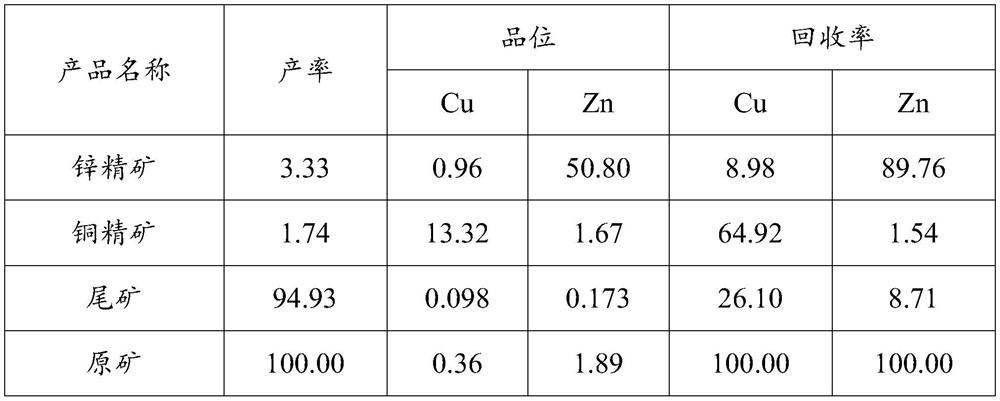

Embodiment 1

[0044]

[0053]

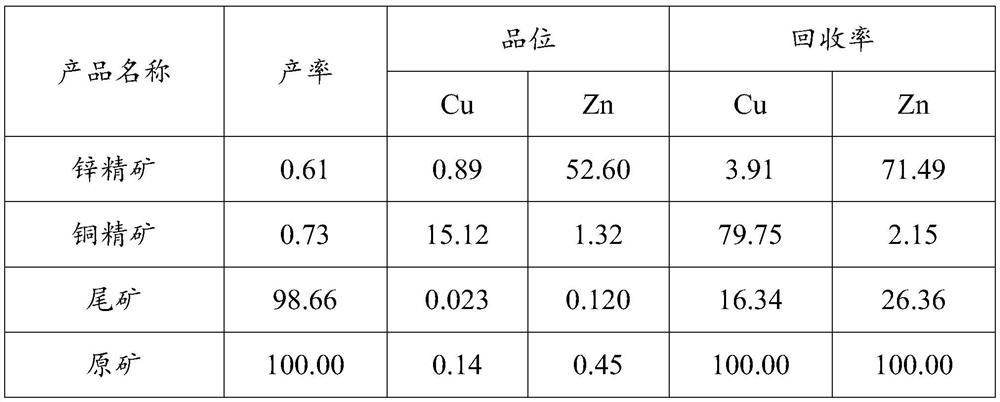

Embodiment 2

[0061]

[0062] The obtained zinc concentrate contains Cu 0.89% and Zn 52.60%, and the copper concentrate contains Cu 15.12% and Zn 1.32%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for beneficiation and separation of copper-zinc sulfide ore, which belongs to the field of mineral processing. The specific method is as follows: the ore containing copper-zinc sulfide ore is ground and classified, and mixed flotation to obtain copper-zinc mixed concentrate; the copper-zinc mixed concentrate is processed by a vertical stirring mill, and the mixed concentrate pulp after the vertical mill treatment is thickened Dehydration treatment, the dense overflow returns to the copper-zinc mixed roughing step, while the dense underflow is slurried and stirred, and the material after slurred is transported to the flotation column for aerated flotation, so as to realize the separation of sphalerite and sphalerite in the copper-zinc mixed concentrate. Other mineral separation purposes. Compared with the traditional process for suppressing zinc by floating copper, the method of the present invention has the advantages of short process, few types of chemicals, low mutual content of concentrate products, etc., and has wide industrial application prospects.

Description

A kind of method for beneficiation and separation of copper-zinc sulfide ore technical field [0001] The present invention relates to the field of mineral processing, and specifically provides a method for beneficiation and separation of copper-containing zinc sulfide ore. Background technique [0002] The copper-containing zinc sulfide ore ores are mostly produced in hydrothermal filling metasomatism and skarn-type deposits. The peculiar lithogenesis and mineralization of the deposit lead to the extremely complex ore structure and structure of the common copper-zinc sulfide deposits at home and abroad. Miscellaneous, some ores are filled with fine-grained chalcopyrite and sphalerite and are filled with each other in the shape of veinlets, interwoven network veins or wrapping In the intergranular or fissures of pyrite, the dissociation and flotation separation of copper-zinc minerals in this type of ore are extremely difficult. In the process of ore grinding, the Cu bet...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B03B9/00B03D1/02B03D1/08

CPCB03B9/00B03D1/02B03D1/08Y02W30/52

Inventor 肖骏陈代雄董艳红杨建文蔡冰冰胡波曾惠明

Owner HUNAN RES INST FOR NONFERROUS METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com