Precoated sand molding auxiliary mechanism capable of efficiently controlling material overflow

An auxiliary mechanism and technology of coated sand, applied in the field of coated sand, can solve the problems of iron and steel casting, casting defects, affecting production effect, etc., and achieve the effect of improving molding effect, reducing leakage and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

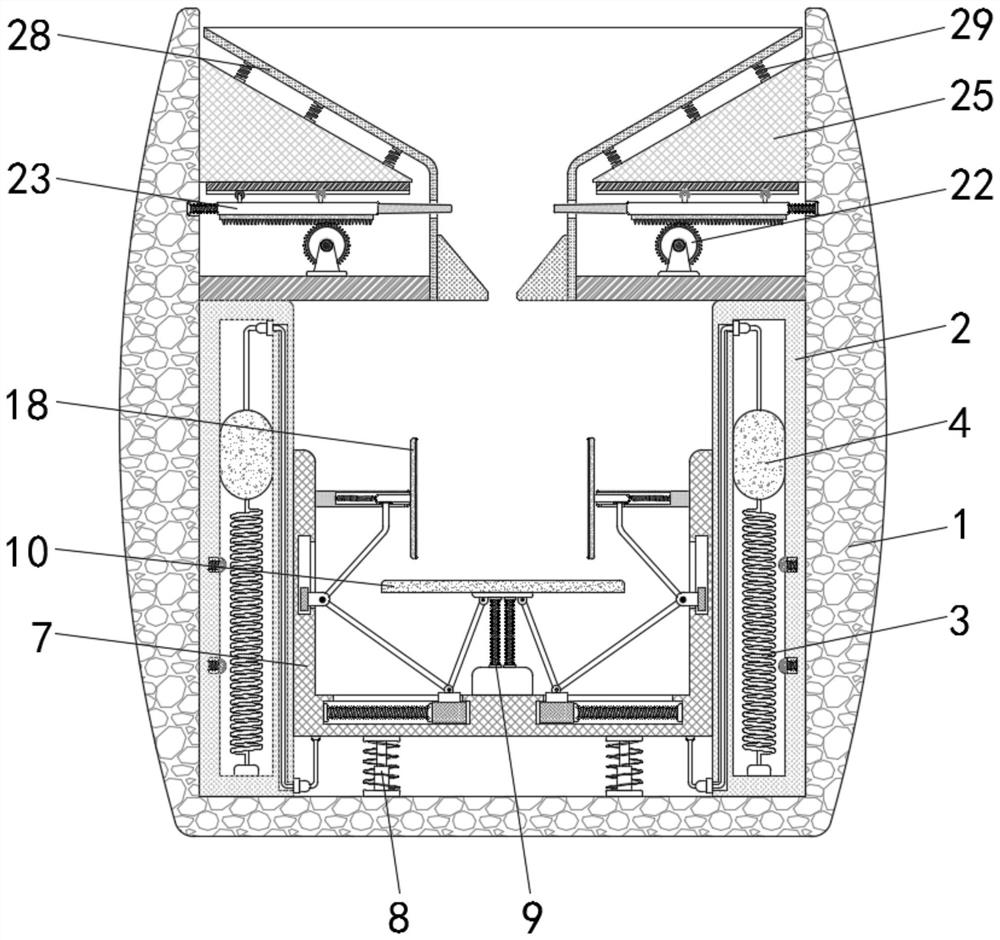

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] as attached figure 1 to attach Image 6 Shown:

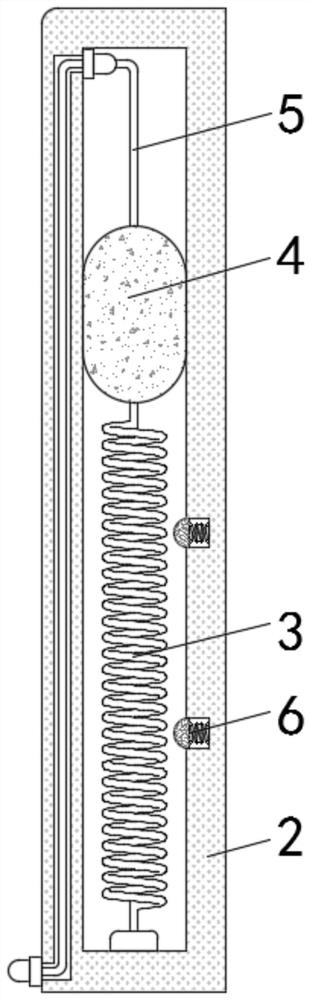

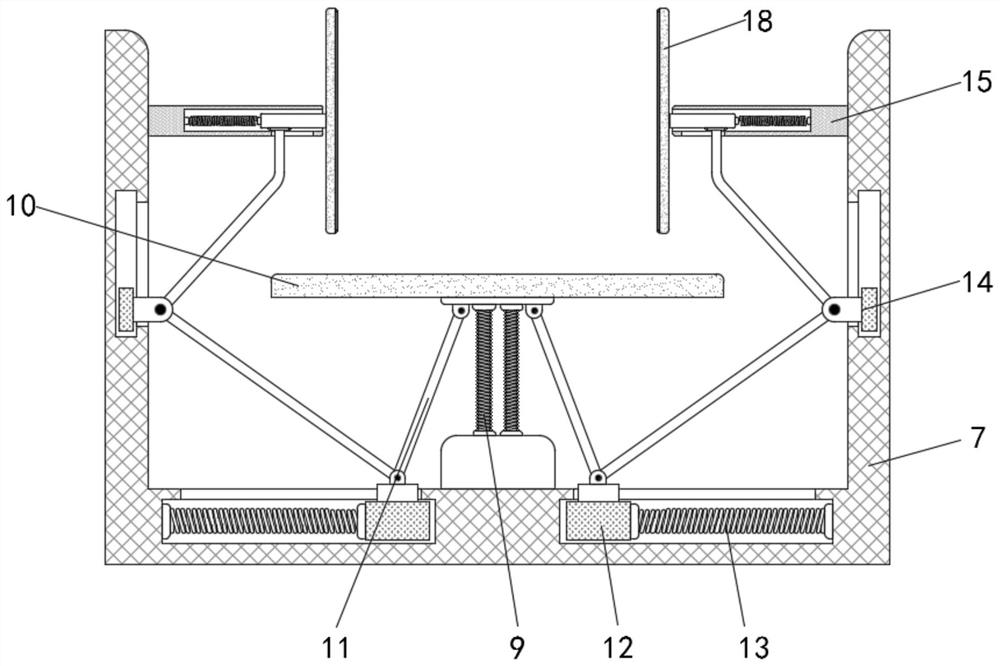

[0026] The invention provides a coated sand molding auxiliary mechanism for efficiently controlling material overflow, which includes a main body 1, a fixing part 2 is installed inside the main body 1, a spring mechanism 3 is installed inside the fixing part 2, and the upper end of the spring mechanism 3 is fixed. An induction airbag 4 is connected, and an inductor 6 is installed on the inner wall of the fixed part 2. The inductor 6 is electrically connected to the induction airbag 4, and the induction airbag 4 is in contact with the inductor 6, so that the driving gear 22 generates kinetic energy. The driving gear 22 is rotated and meshed to drive the movable gear baffle 23 to move. The upper end of the induction airbag 4 is provided with a pull cord 5 connected thereto. The support mechanism 8, through the continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com