Integrated working partition chamber of powder forming machine

A forming machine and integrated technology, applied in the field of work partitions, can solve problems such as unsightly, loud noise, unsafe, etc., and achieve the effect of improving comfort, reducing the impact of noise on the surrounding space, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment shows an integrated working compartment for single-axis and double-axis adjustment precision powder forming machine.

[0033] Such as Figure 1-11 , the partition part composed of the different partition surfaces 3 of the front partition surface, the rear partition surface, the left partition surface, the right partition surface and the top partition surface divides the surrounding space into an interior space and an exterior space. Image 6 The powder forming machine 1 shown is placed in the inner space.

[0034] Figure 7-Figure 11 It shows that the powder molding machine 1 is installed in the inner space of the integrated work compartment 2 .

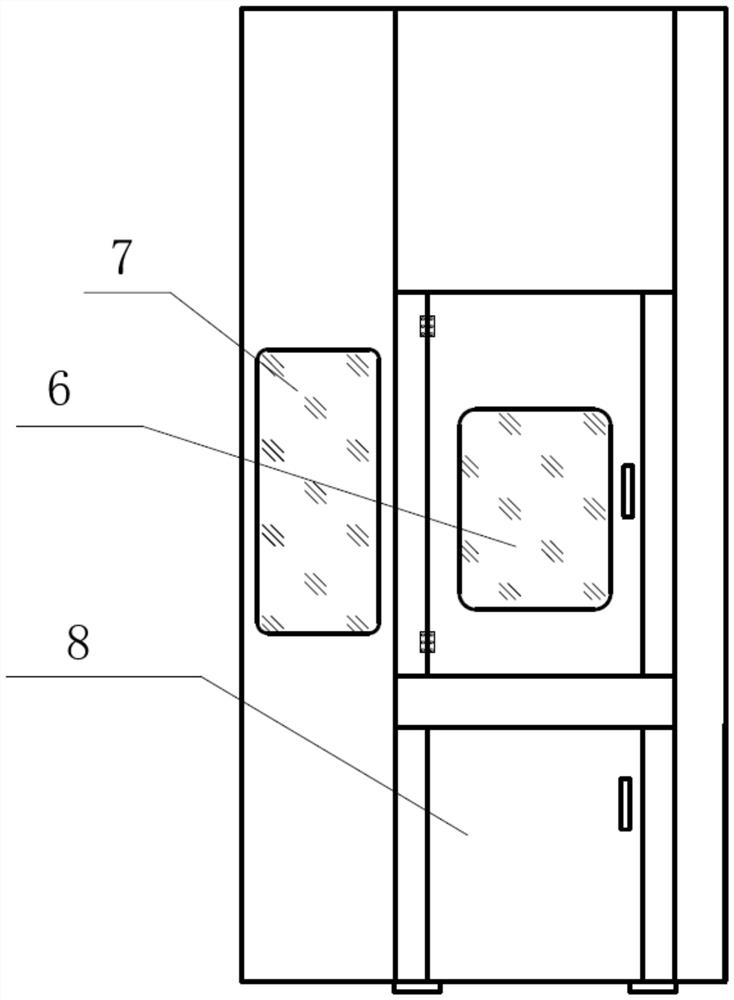

[0035] Figure 1-Figure 5 It shows the openings provided on each partition surface 3 for various communication between the internal space and the external space;

[0036] in,

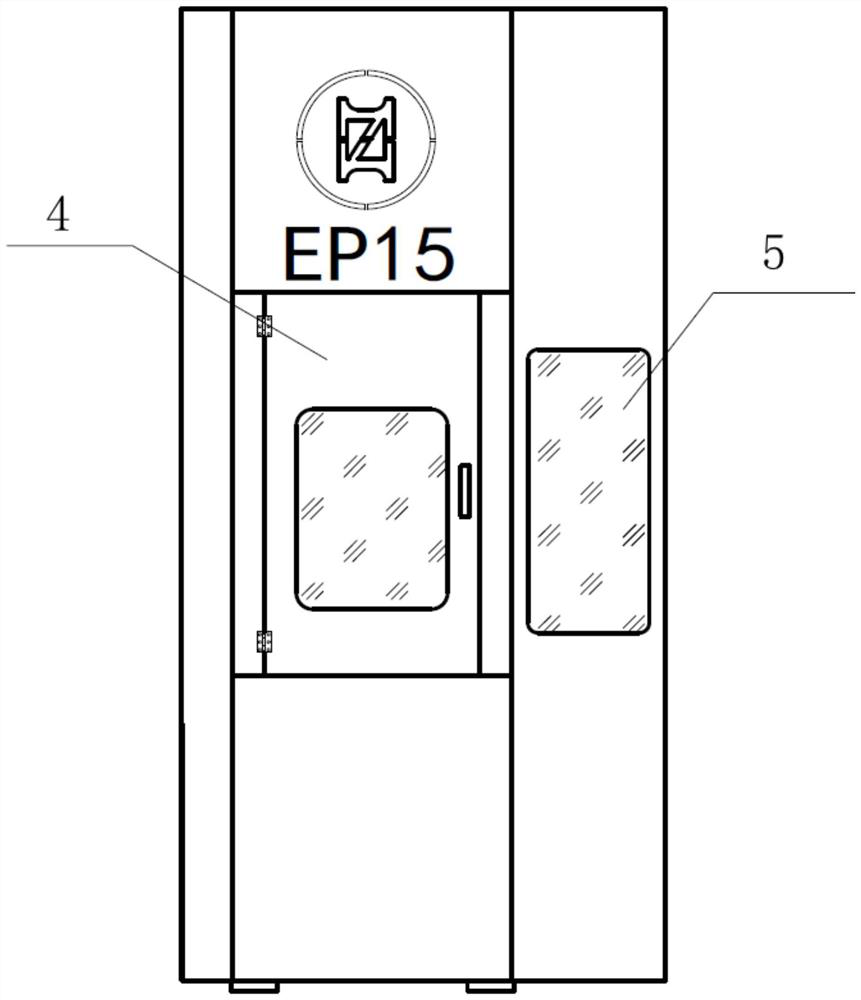

[0037] figure 1 The front mold loading and unloading port 4 and the front viewing window 5 on the front partition surface are sho...

Embodiment 2

[0042] Others are the same as in Example 1. The opening of the integrated work partition surface includes a protective door, and the protective door includes a control device, which can be set to an open or closed state according to the working state of the powder forming machine. The control device also includes a self-locking device. When the powder forming machine is in a working state that may endanger the safety of personnel, the self-locking device can automatically lock the protective door so that the protective door cannot be opened to ensure safety. The control device also includes a shutdown protection device. When the powder molding machine is in a working state that may endanger the safety of the operator, if the protective door is forcibly opened, the shutdown protection device will send a signal to stop the powder molding machine.

Embodiment 3

[0044] Others are the same as in Example 1. Such as Figure 7 The model indicator light 13 and the trademark indicator light 14 of the one-piece work compartment shown, when the powder forming machine is working normally, the model indicator light 13 presents a stable blue light; when the powder forming machine breaks down, the trademark indicator light 14 Flashes orange light to alert operator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com