Device for automatically and efficiently cutting off waste steel rails

A rail and waste technology, which is applied in the field of automatic and efficient cutting of waste rail devices, can solve the problems of high risk factor, limited service life of rails, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

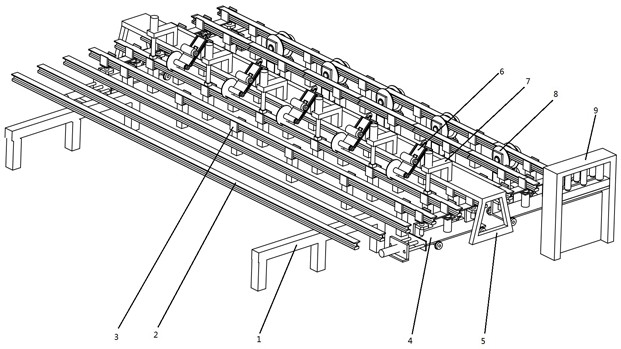

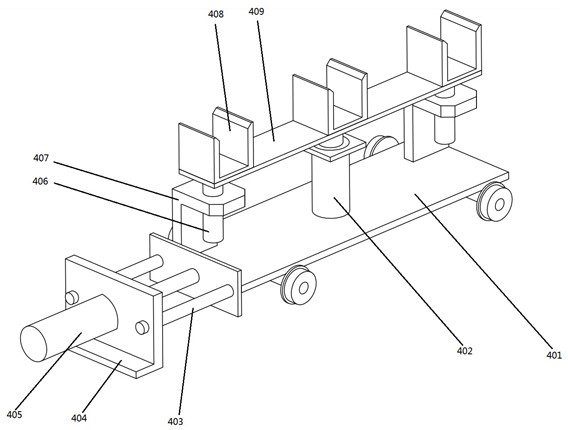

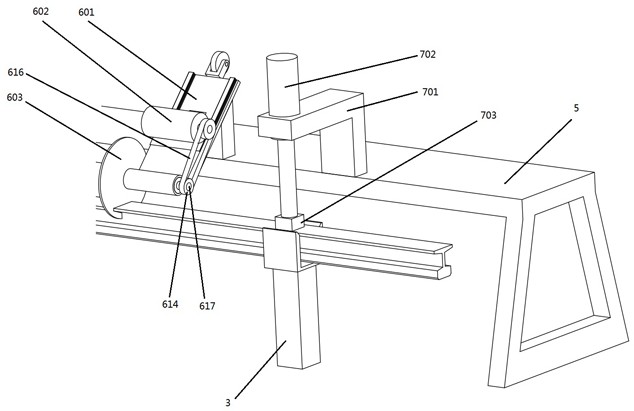

[0027] Example 1, such as figure 1 As shown in —7, the device for automatically and efficiently cutting waste rails includes a rail placement frame 1, the rail placement frame 1 is used to place waste rails 2, the right side of the rail placement frame 1 is provided with a fixed frame 5, and the right side of the rail placement frame 1 is provided with a Multiple rows of evenly arranged bracket mechanisms 3 for supporting the rail 2, the bracket mechanism 3 is used to place the rail 2, the structure of the bracket mechanism 3 is not limited, and the placement of the rail 2 can be realized without rotation That is, two symmetrically distributed moving mechanisms 4 for laterally moving the rail 2 are respectively provided on both sides of the supporting mechanism. , supporting plate 409, mobile frame bracket 408, transverse guide rod 403, longitudinal guide rod 406, L-shaped guide plate 407, the transverse electric cylinder 405 is fixed on the fixed plate 404, and the output end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com