High-density shaving board cutting processing technology

A processing technology, particleboard technology, applied in the field of high-density particleboard cutting processing technology, can solve the problems that the cutting size of particleboard cannot be accurately guaranteed, reduce the overall quality of particleboard cutting, and the cut of particleboard is not beautiful enough, etc., so as to improve the overall quality of cutting , enhance the aesthetics of the incision, and reduce noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

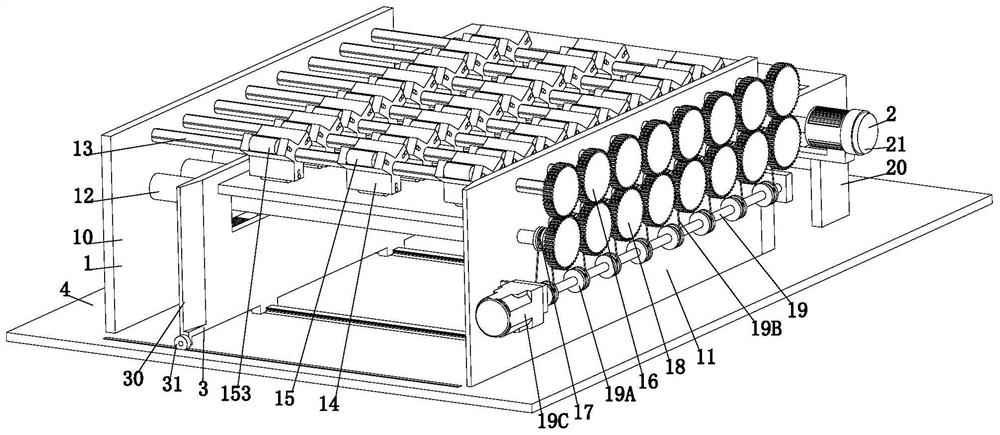

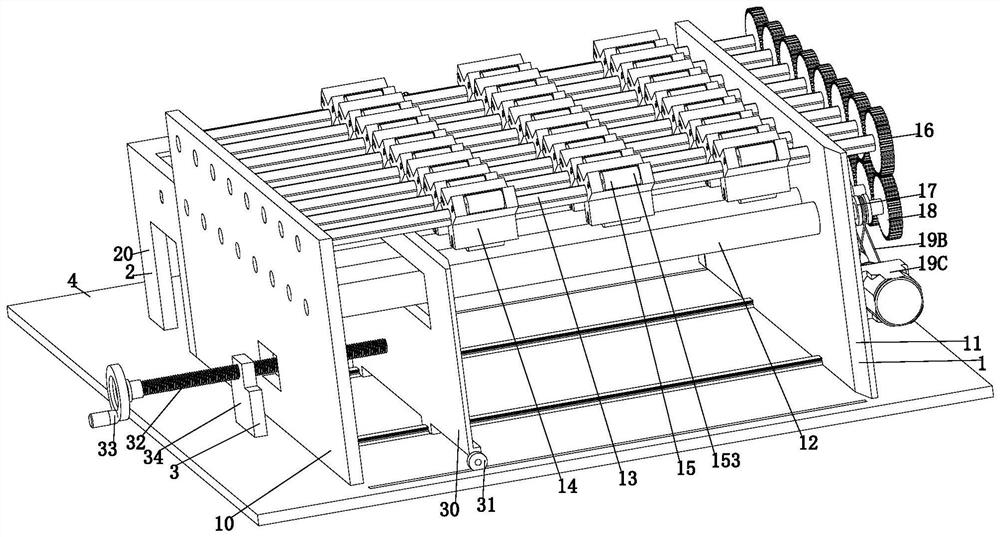

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific drawings. It should be noted that, in the case of no conflict, the embodiments and Features in the embodiments can be combined with each other.

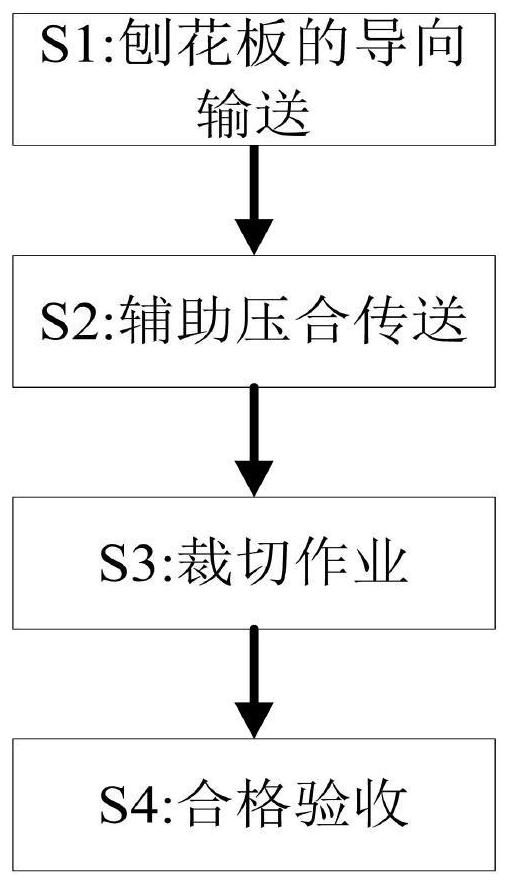

[0034] Such as Figure 1 to Figure 9 As shown, a high-density particleboard cutting process uses a particleboard cutting and processing equipment, which includes a rolling conveying mechanism 1, an actuator 2, a guiding mechanism 3 and a bottom plate 4. The specific method of cutting the particleboard to the specified width by the cutting processing equipment is as follows:

[0035] S1. Guided delivery of particle boards: the particle boards are transported and transported by the rolling conveying mechanism 1, and the moving forward direction of the particle boards is guided by the guiding mechanism 3, so that the pa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap