Garment fabric with good antibacterial performance

A clothing and fabric technology, applied in the field of clothing fabrics with good antibacterial performance, can solve the problems of poor antibacterial performance, anti-wrinkle and antistatic effects, etc., and achieve the effects of improving shape retention, moisture absorption and breathability, and antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

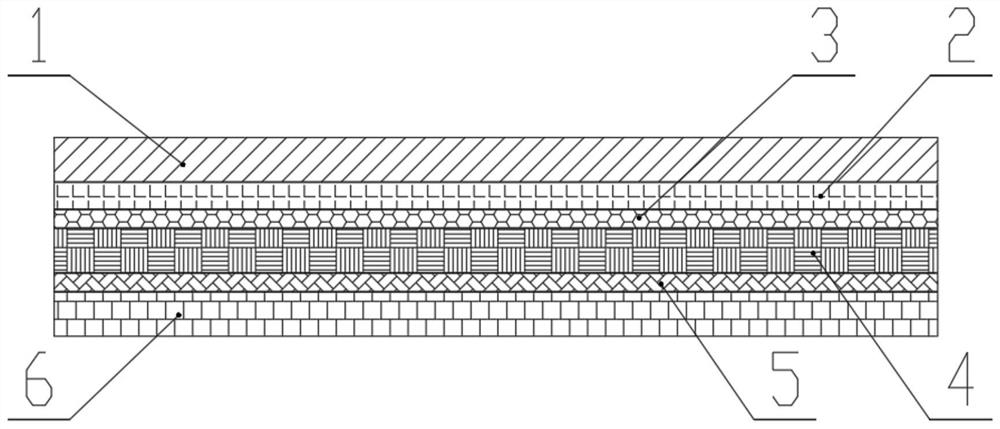

Image

Examples

Embodiment 1

[0028] A clothing fabric with good antibacterial performance, comprising the following components in parts by weight: 12 parts by weight of an outer protective layer, 8 parts by weight of an antibacterial layer, 5 parts by weight of an anti-wrinkle layer, and 5 parts by weight of a thermal insulation layer 20 parts, 3 parts by weight of the antistatic layer, and 10 parts by weight of the skin-friendly layer.

[0029] The clothing cloth with good antibacterial properties comprises the following steps:

[0030] S1: Take an appropriate amount of polyester fiber, comb the polyester fiber, remove impurities, mix it into a sliver and put it into the cylinder, and combine it with 6~8 slivers to improve the unevenness of the long segment of the sliver. The drawn sliver is stretched and twisted to make the sliver have a certain strength, and the warp beam is woven on the shuttle loom to form an outer protective layer through the shuttle loom;

[0031] S2: By weighing an appropriate am...

Embodiment 2

[0038] A clothing fabric with good antibacterial properties, comprising the following components in parts by weight: 13 parts by weight of an outer protective layer, 10 parts by weight of an antibacterial layer, 7 parts by weight of an anti-wrinkle layer, and 10 parts by weight of a thermal insulation layer 25 parts, 5 parts by weight of the antistatic layer, and 10 parts by weight of the skin-friendly layer.

[0039] The clothing cloth with good antibacterial properties comprises the following steps:

[0040] S1: Take an appropriate amount of polyester fiber, comb the polyester fiber, remove impurities, mix it into a sliver and put it into the cylinder, and combine it with 6~8 slivers to improve the unevenness of the long segment of the sliver. The drawn sliver is stretched and twisted to make the sliver have a certain strength, and the warp beam is woven on the shuttle loom to form an outer protective layer through the shuttle loom;

[0041] S2: By weighing an appropriate a...

Embodiment 3

[0048] A clothing fabric with good antibacterial performance, comprising the following components in parts by weight: 12 parts by weight of an outer protective layer, 10 parts by weight of an antibacterial layer, 6 parts by weight of an anti-wrinkle layer, and 5 parts by weight of a thermal insulation layer 30 parts, 6 parts by weight of the antistatic layer, and 8 parts by weight of the skin-friendly layer.

[0049] The clothing cloth with good antibacterial properties comprises the following steps:

[0050] S1: Take an appropriate amount of polyester fiber, comb the polyester fiber, remove impurities, mix it into a sliver and put it into the cylinder, and combine it with 6~8 slivers to improve the unevenness of the long segment of the sliver. The drawn sliver is stretched and twisted to make the sliver have a certain strength, and the warp beam is woven on the shuttle loom to form an outer protective layer through the shuttle loom;

[0051] S2: By weighing an appropriate am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com