CO2 treatment gasification gray water recycling device and method

A CO2 and grey water technology, applied in water softening and other directions, can solve the problems of difficult to meet environmental protection requirements, increase the cost of gasification grey water treatment, etc., and achieve the effect of simple structure and reasonable process design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

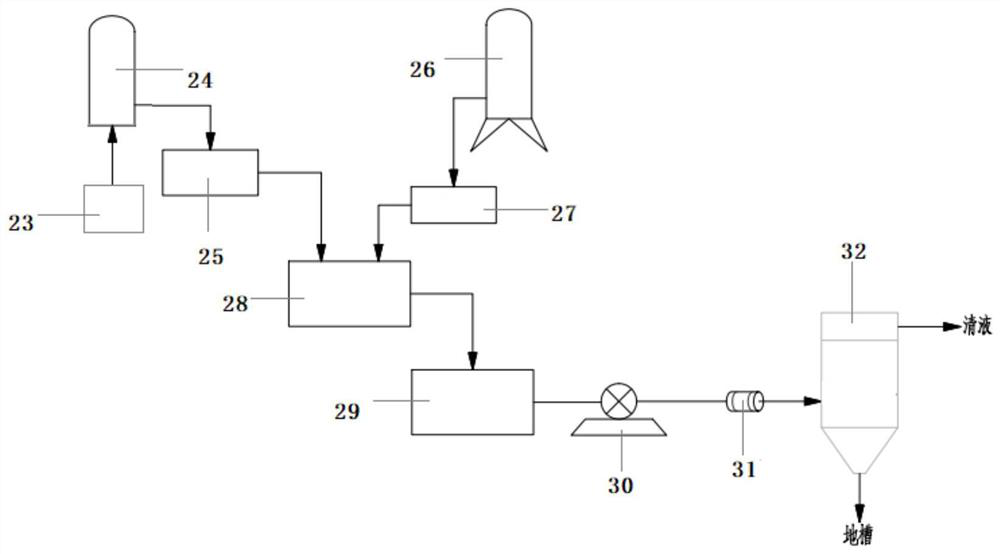

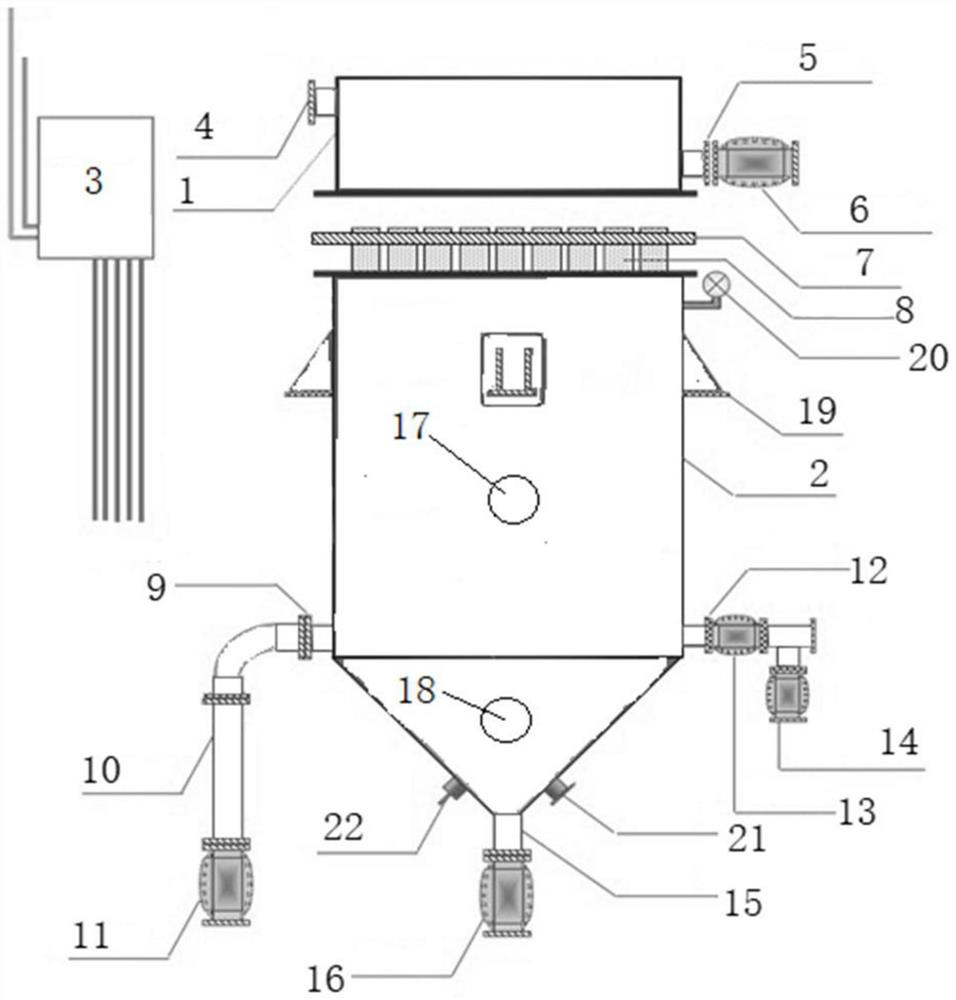

[0029] a CO 2 Treatment of gasification gray water reuse device, including gasification furnace 23, flash tank 24, buffer tank 25, dissolved gas reactor 26, CO 2 Storage tank 27, decalcification reaction tank 29 and automatic backwashing surface filter 32, the gasifier 23 is connected to the buffer tank 25 through the flash tank 24, and the buffer tank 25 reacts with the dissolved gas through a lift pump The gas-dissolving reactor 26 is connected with the device 26. The gas-dissolving reactor 26 is prepared by the application number CN201320285194. The gas-dissolving reactor 26 makes full use of carbon dioxide gas to reduce the hardness of the reclaimed water and reduce the emission of carbon dioxide; the device dissolves the gas under pressure to make the carbon dioxide Fully mixed with reclaimed water, no need to use mixing devices such as stirring, reducing power consumption and operating costs.

[0030] The CO 2 Storage tank 27 is connected with dissolved gas reactor 26 ...

Embodiment 2

[0045] like figure 1 Shown: a CO 2 A method for reusing gasification gray water, the method for reusing comprises the following steps:

[0046] Step 1: Introduce the gasified black water discharged from the gasification furnace through the pipeline to enter the flash tank to form gasified gray water. The formed gasified gray water enters the buffer tank for natural precipitation, and uses lime water to adjust the pH value of the wastewater to 8 ;The temperature of gasified black water is 100℃, the solid content is 14000mg / l, the turbidity is 700NTU, and the flow rate is 5m 3 / h.

[0047] Step 2: Send the gasified gray water supernatant in the buffer tank to the dissolved air reactor through the lifting pump. The temperature of the gasified gray water supernatant is 60°C, the solid content is 2750mg / l, and the turbidity is: 120NTU, CO 2 CO in storage tank 2 Enter the dissolved air reactor through the air-temperature gasifier and mix effectively and fully with the supernatan...

Embodiment 3

[0052] like figure 1 Shown: a CO 2 A method for reusing gasification gray water, the method for reusing comprises the following steps:

[0053] Step 1: Introduce the gasified black water discharged from the gasification furnace through the pipeline to enter the flash tank to form gasified gray water. The formed gasified gray water enters the buffer tank for natural precipitation, and uses lime water to adjust the pH value of the wastewater to 9. ;The temperature of gasified black water is 110℃, the solid content is 10000mg / l, the turbidity is 400NTU, and the flow rate is 5m 3 / h.

[0054] Step 2: Send the gasified gray water supernatant in the buffer tank to the dissolved air reactor through the lifting pump. The temperature of the gasified gray water supernatant is 75°C, the solid content is 2050mg / l, and the turbidity is: 80NTU, CO 2 CO in storage tank 2 Enter the dissolved air reactor through the air-temperature gasifier and mix effectively and fully with the supernatan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com