Si3N4 ceramic material and preparation method thereof

A technology of ceramic material, -si3n492, applied in the field of preparation of silicon nitride ceramics, can solve the problems of reduced wear resistance of silicon nitride ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

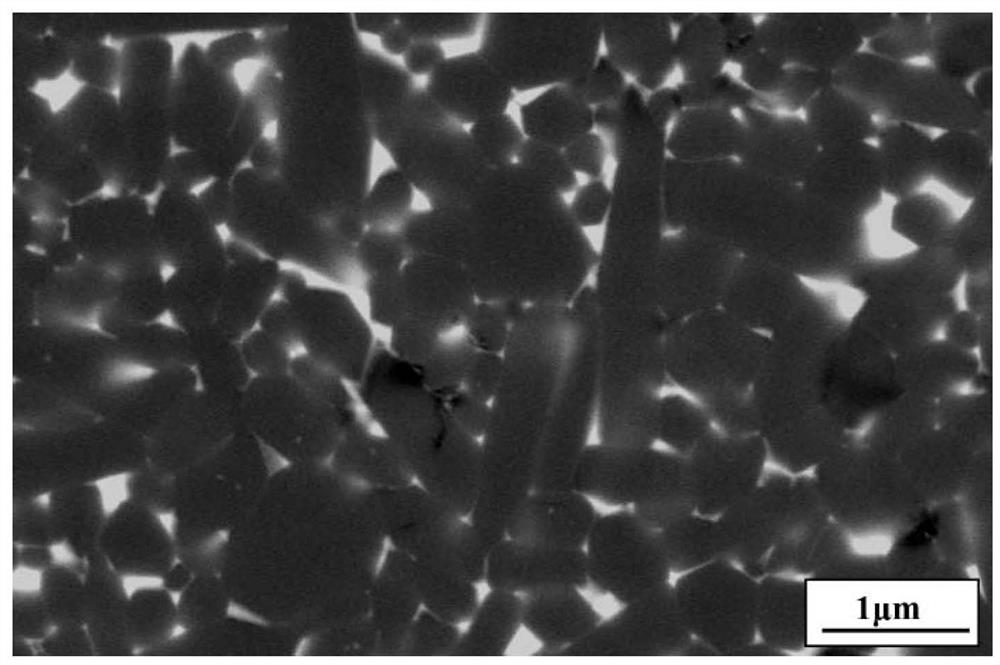

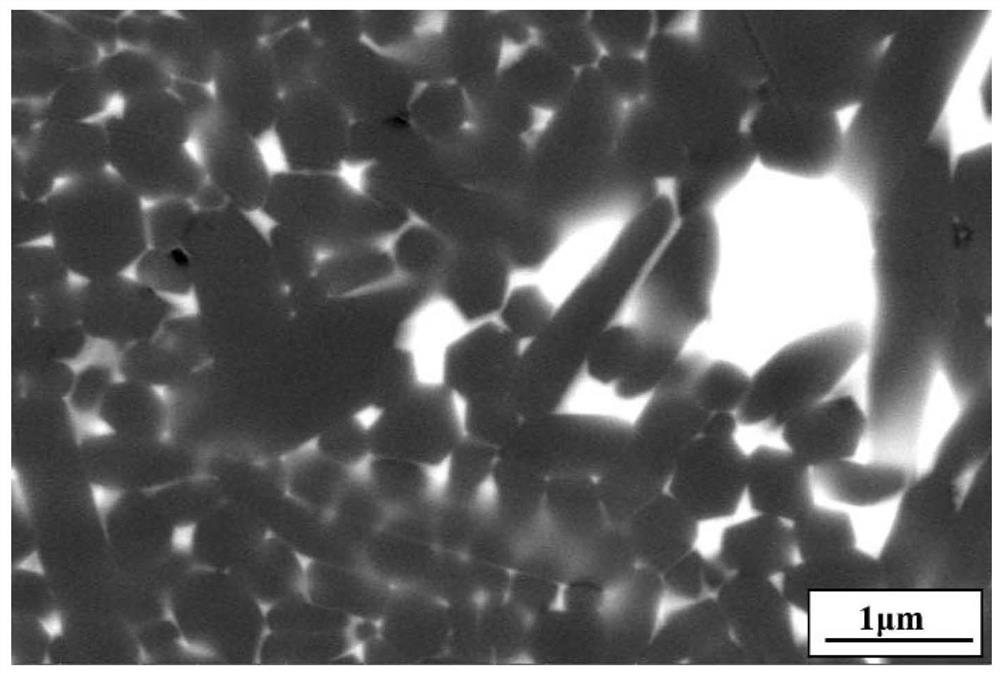

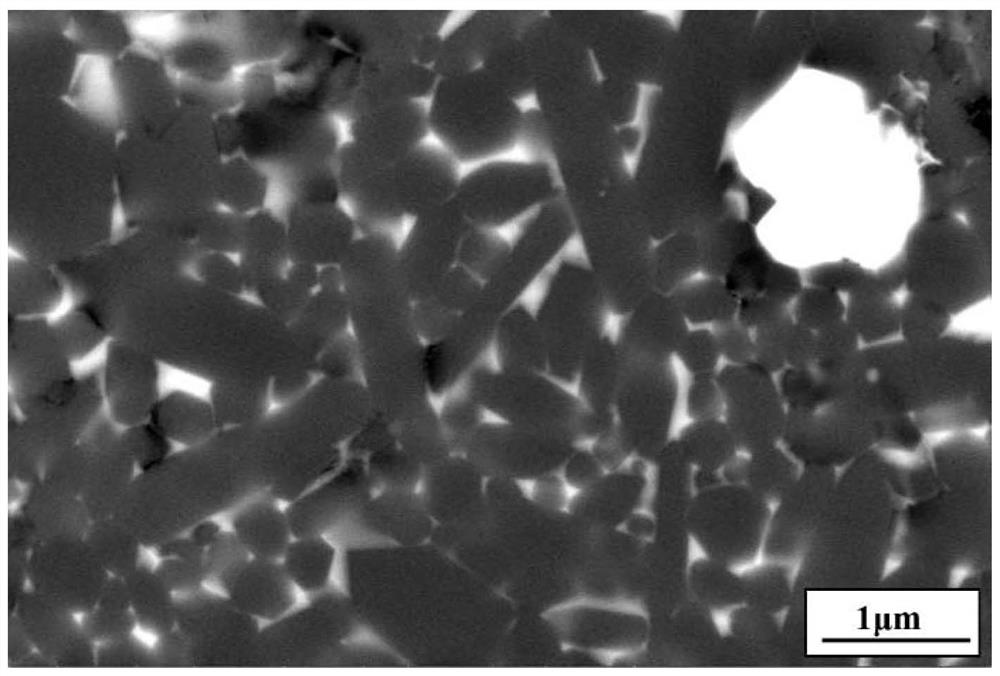

Image

Examples

Embodiment 1

[0038] A kind of Si 3 N 4 Ceramic material and preparation method thereof, comprising the following steps:

[0039] S1: Weigh 95g Si 3 N 4 , 1.73g Al 2 o 3 , 1.27g Y 2 o 3 , 1.00g Fe 2 o 3 A total of 100g and 1.00g AlN;

[0040] S2: The mixed powder in step S1 is configured into a slurry with a certain solid content, and the planetary ball mill is 3h, and the rotating speed is 400rpm;

[0041] S3: Grinding the slurry obtained in step S2 after drying, passing through a 400-mesh sieve, preforming under a pressure of 20MPa by dry pressing, and then forming by cold isostatic pressing at 300MPa;

[0042] S4: the ceramic biscuit obtained in step S3 is put into a BN mould, and placed in a gas pressure sintering furnace, filled with N 2 As a protective gas, sinter at 1750°C and 2MPa pressure for 240 minutes, then perform hot isostatic pressing at 1700°C for 2.5 hours at 200MPa, the relative density is 99.4%, and the bending strength is 1305.7± 15.2MPa, fracture toughness o...

Embodiment 2

[0044] A kind of Si 3 N 4 Ceramic material and preparation method thereof, comprising the following steps:

[0045] S1: Weigh 95g Si 3 N 4 , 0.6g Al 2 o 3 , 2.65g Y 2 o 3 , 0.75g Fe 2 o 3 A total of 100g and 1.00g AlN;

[0046] S2: The mixed powder in step S1 is configured into a slurry with a certain solid content, and the planetary ball mill is 3h, and the rotating speed is 400rpm;

[0047] S3: Grinding the slurry obtained in step S2 after drying, passing through a 400-mesh sieve, preforming under a pressure of 20MPa by dry pressing, and then forming by cold isostatic pressing at 300MPa;

[0048] S4: the ceramic biscuit obtained in step S3 is put into a BN mould, and placed in a gas pressure sintering furnace, filled with N 2 As a protective gas, sinter at 1750°C and 2MPa pressure for 240 minutes, then carry out hot isostatic pressing at 1700°C, holding time for 1h, and pressure 200MPa, that is, the relative density is 99.3%, and the bending strength is 1302.8±21....

Embodiment 3

[0050] A kind of Si 3 N 4 Ceramic material and preparation method thereof, comprising the following steps:

[0051] S1: Weigh 95g Si 3 N 4 , 2.01g Al 2 o 3 , 1.49g Y 2 o 3 , 0.75g Fe 2 o 3 And 0.75g AlN a total of 100g;

[0052] S2: The mixed powder in step S1 is configured into a slurry with a certain solid content, and the planetary ball mill is 3h, and the rotating speed is 400rpm;

[0053] S3: Grinding the slurry obtained in step S2 after drying, passing through a 400-mesh sieve, preforming under a pressure of 20MPa by dry pressing, and then forming by cold isostatic pressing at 300MPa;

[0054] S4: the ceramic biscuit obtained in step S3 is put into a BN mould, and placed in a gas pressure sintering furnace, filled with N 2 As a protective gas, sinter at 1750°C and 2MPa pressure for 240 minutes, and then perform hot isostatic pressing at 1650°C for a holding time of 0.5h and an air pressure of 150MPa. The relative density is 99.6%, and the bending strength is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com