Preparation method of methoxyamine hydrochloride and preparation method of N-methoxyacetamide

A technology of methoxyacetamide and methoxylamine hydrochloride, which is applied in the field of preparation of methoxylamine hydrochloride, can solve the problem of insufficient yield, insufficient purity of methoxylamine hydrochloride, and limited methoxylamine hydrochloride. Problems such as the promotion and application of hydrochloride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

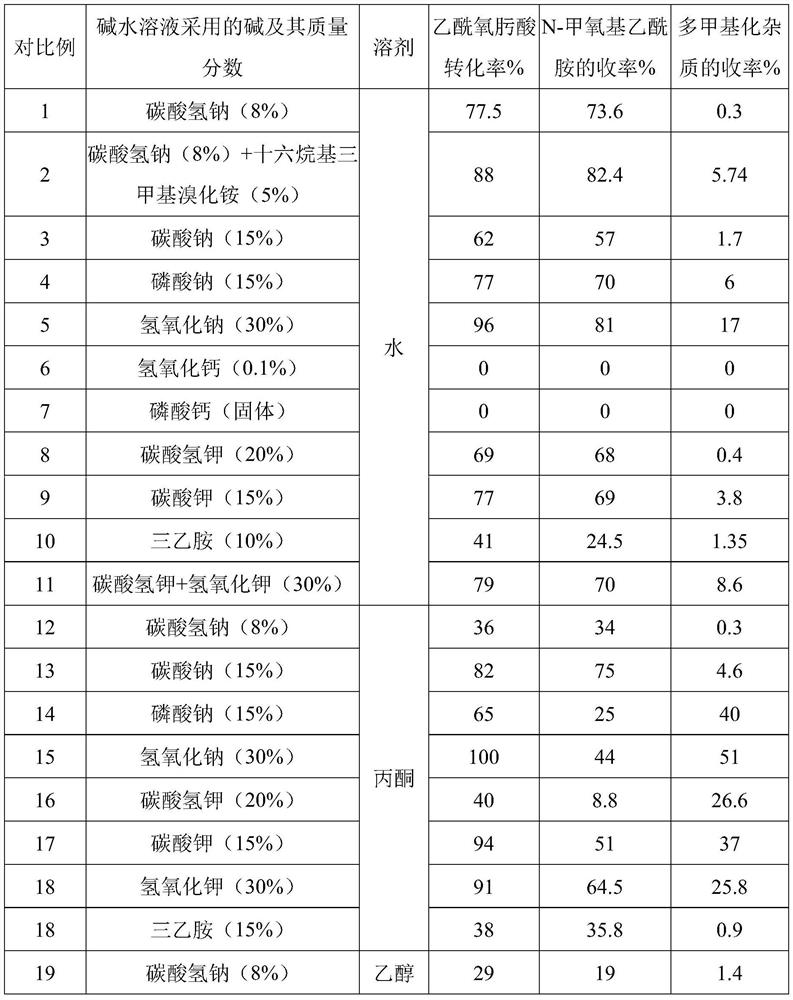

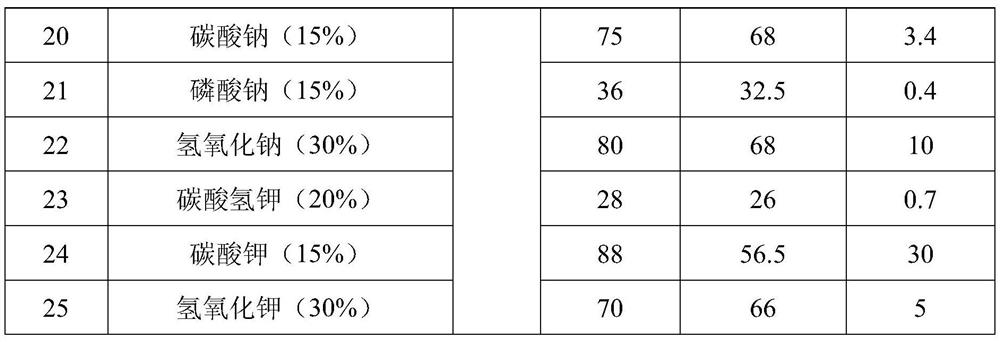

Examples

Embodiment 1

[0039] The preparation method of the methoxylamine hydrochloride of the present embodiment may further comprise the steps:

[0040] 1) Add 0.10 mol of sodium bicarbonate and 3.52 mol of sodium hydroxide to 200 g of water and mix evenly to obtain a composite alkali aqueous solution (i.e. a mixed aqueous solution);

[0041] 2) Add 108g (1.44mol) acetylhydroxamic acid and 200g water to the reaction flask and mix to obtain a reaction solution. Control the temperature of the reaction solution at 10°C, add 181.6g (1.44mol) dimethyl sulfate dropwise, and simultaneously add compound Alkali aqueous solution, control the pH of the reaction system to 7.0-7.5, drop in 2 hours, and stir for 0.5h after adding dimethyl sulfate. Then dropwise add 27.2g (0.22mol) dimethyl sulfate, dropwise add aqueous solution of composite base, control reaction system pH=7.0-7.5, stir 0.5h after dropping, then dropwise add 45.4g (0.36mol) dimethyl sulfate, At the same time, the aqueous solution of compound a...

Embodiment 2

[0044] The preparation method of the methoxylamine hydrochloride of the present embodiment may further comprise the steps:

[0045] 1) Add 0.2mol of sodium bicarbonate and 2.3mol of sodium hydroxide to 200g of water and mix evenly to obtain a composite alkali aqueous solution (i.e. a mixed aqueous solution);

[0046] 2) Add 108g (1.44mol) of acetylhydroxamic acid and 252g of water into the reaction flask and mix to obtain a reaction solution. Control the temperature of the reaction solution at 20°C, add 163.4g (1.30mol) of dimethyl sulfate dropwise, and simultaneously add compound Alkaline aqueous solution, control the pH of the reaction system to 7.5-8.0, drop it in 2 hours, and stir for 0.5 h after adding dimethyl sulfate. Then continue to dropwise add 18.1g (0.14mol) of dimethyl sulfate, and dropwise add a complex alkali aqueous solution at the same time, control the pH of the reaction system=7.5-8.0, stir for 0.5h after dropping, then add dropwise 27.2g (0.22mol) of dimeth...

Embodiment 3

[0049] The preparation method of the methoxylamine hydrochloride of the present embodiment may further comprise the steps:

[0050] 1) Add 0.15 mol of sodium bicarbonate and 3.0 mol of sodium hydroxide to 200 g of water and mix evenly to obtain a composite alkali aqueous solution (i.e. a mixed aqueous solution);

[0051] 2) Add 108g (1.44mol) of acetylhydroxamic acid and 162g of water into the reaction flask and mix to obtain a reaction solution. Control the temperature of the reaction solution at 30°C, add 154.3g (1.22mol) of dimethyl sulfate dropwise, and simultaneously add the compound Alkali aqueous solution, control the pH of the reaction system to 8-9, drop after 2 hours, and stir for 0.5h after adding dimethyl sulfate. Then continue to add dropwise 9.1g (0.08mol) dimethyl sulfate, and dropwise add the aqueous solution of compound alkali to control the pH of the reaction system=8-9, stir for 0.5h after dropping, then add dropwise 18.1g (0.14mol) dimethyl sulfate , and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com