Brewing process of northern clean and elegant raw wine

A clean and elegant, original wine technology, applied in the field of winemaking, can solve the problems of limited adaptability, long pressing period, difficult fermentation, etc., and achieve the effect of improving the quality of original wine, reducing acidity and improving the quality of wine production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

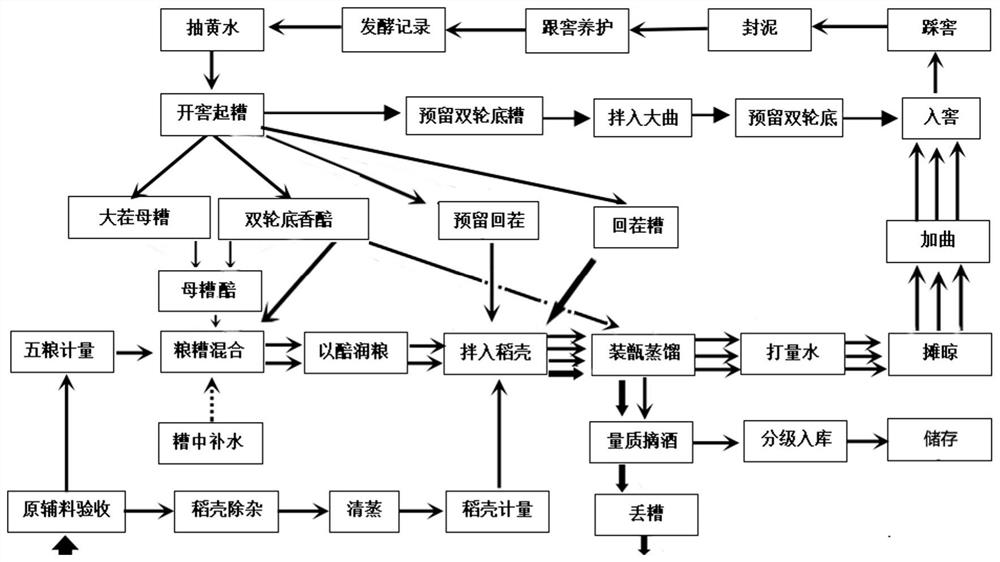

[0042] Embodiment 1 A kind of brewing process of northern Jingya original wine

[0043] A kind of brewing process of northern Jingya original wine, see figure 1 , first of all, after the acceptance of raw and auxiliary materials, carry out raw material pretreatment: ①Wuliang measurement: weigh 480kg of sorghum, 264kg of glutinous rice, 216kg of rice, 144kg of wheat, and 96kg of corn, and mix them evenly to obtain grain; Drying and obtaining rice husks; then follow the following steps in sequence:

[0044] S1. Replenish water in grains, mix grain grains, moisten grains with unstrained spirits:

[0045] Detect the moisture content of Shuanglunbotan fermented grains and large stubble grains. If the moisture is lower than 62%, add 25kg of water per cubic Shuanglunbottom fermented grains / large stubble grains for every one percentage point lower;

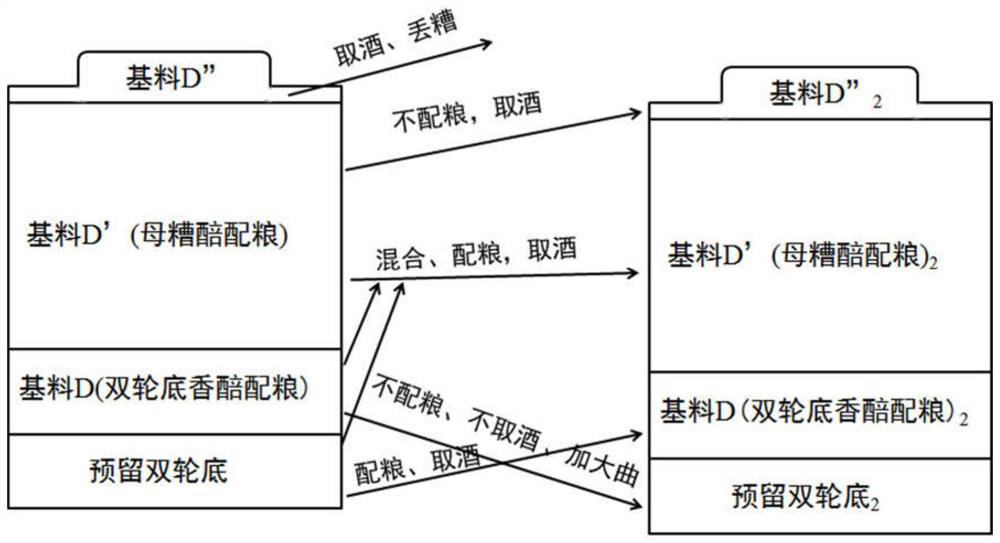

[0046] Combine 300kg grain and 0.96m 3 Shuanglunbottom fermented grains are mixed (the volume ratio of grain and Shuanglunbottom dist...

Embodiment 2~8

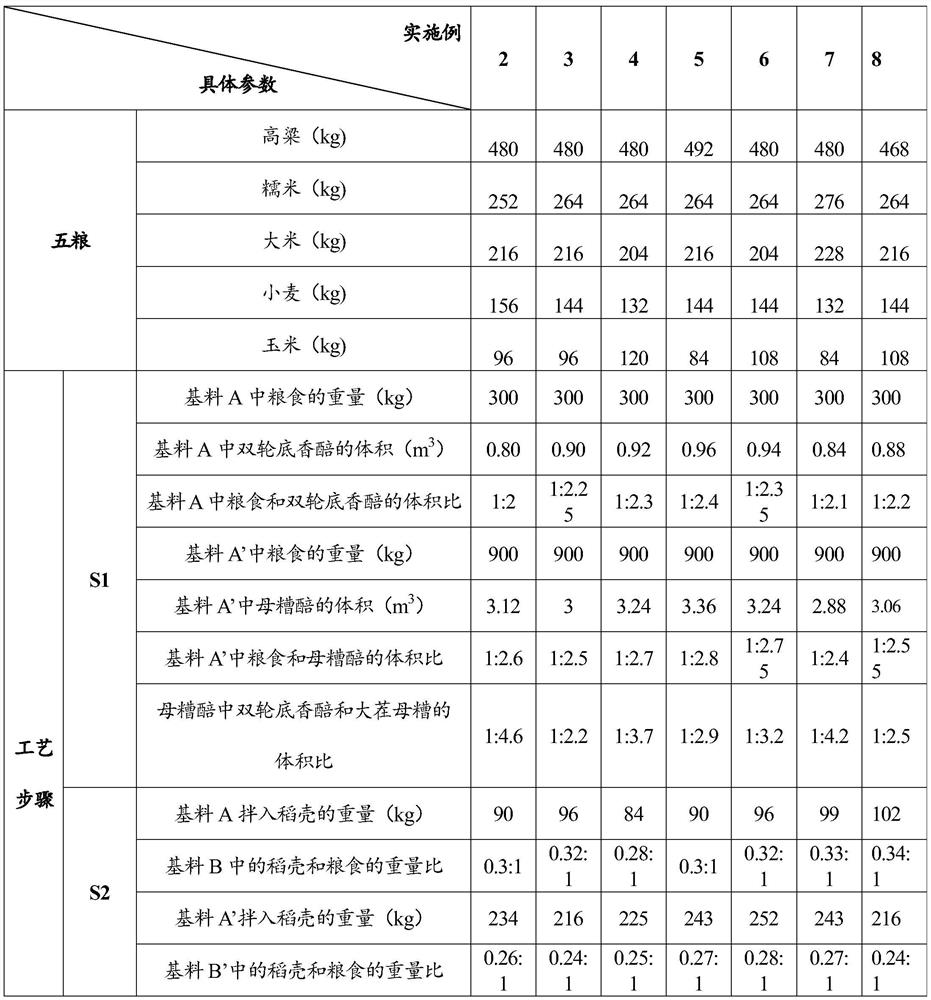

[0068] Examples 2-8 The brewing process of northern Jingya original wine

[0069] Examples 2 to 8 are respectively a brewing process of a northern Jingya original wine, the process steps of which are similar to those of Example 1, the only difference being that the relevant parameters are different, see Table 1 for details.

[0070] Table 1 Example 2-8 List of specific steps and parameters of the brewing process of northern Jingya original wine

[0071]

[0072]

[0073] Comparative Example 1'

[0074] Comparative Example 1' is a liquor brewing process, the process steps of which are similar to those of Example 1, the only difference being that: ① the water in the cellar of this process is 59%; Only use large stubble grains and grains to mix grains and moisten materials to obtain DA'. In step S5, only the reserved double-wheel bottom and base material DD' are put into the cellar, stepped on the cellar, and sealed with mud for a period of 60 days of fermentation ; Base ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com