Connection compensation device for preventing local low temperature of high-temperature furnace chamber prepared from single crystal material

A single crystal material and compensation device technology, which is applied in the directions of polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the problems of uneven radial temperature and axial temperature gradient of the furnace cavity, and reduce the temperature around the rapid heat transfer Influence and other issues, to achieve the effect of increasing the contact surface area and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Next, the technical solutions in the embodiments of the present invention will be described in connection with the embodiments of the present invention, which will be described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments of the invention. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

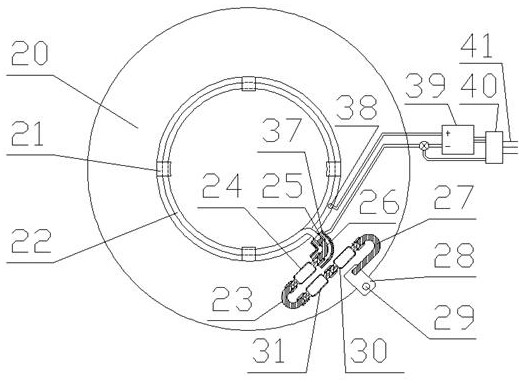

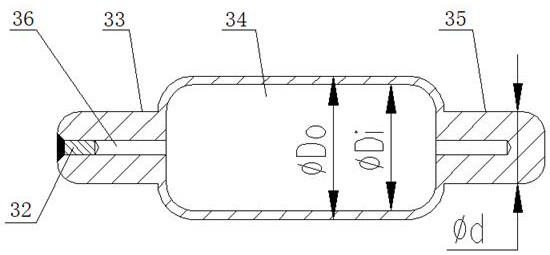

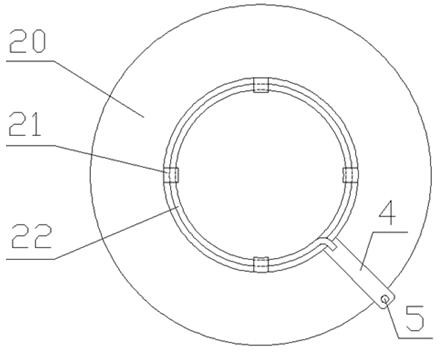

[0020]Such asfigure 1 ,25 shows, a connection compensation device for preventing a single crystal material is preparation high temperature furnace cavity, including thermoelectric coupling support 21, a U-shaped conductive 23, a conductive heat insulating bridge I24, a connection sleeve 25, a L-shaped conductive electromechanical 26, J-shaped conductor 27, connecting conductive sheet 28, conductive heat insulating bridge II30, conductive insulation bridge III31.

[0021]A connection compensation device f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com