Method for modifying flaw on surface of electronic-grade glass fiber cloth

A technology of glass fiber cloth and electronic grade, which is applied in the field of surface defect modification of electronic grade glass fiber cloth, which can solve the problems of unable to meet the needs of downstream customers and abnormal surface defects, so as to reduce the abnormal flow direction of cloth surface defects and improve the flatness , the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

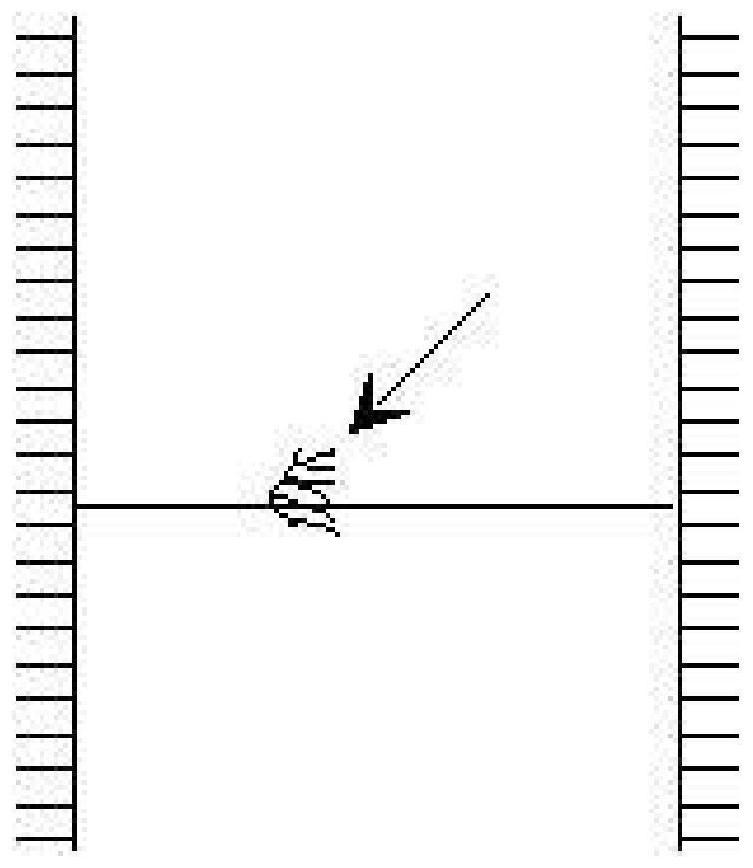

[0033] For 2116 fabric types (basis weight 104g) with abnormal weft breakage in electronic grade fiberglass fabrics, the staff will record the meter length of the defect detected by the CCD before inspection, and repair the defect according to the meter length detected by the CCD during the cloth inspection process. Find it, use a correction needle with a diameter of 0.5mm to pick off the left and right ends of the protruding weft yarn on the surface, and use the correction needle to pick out the protruding yarn, (Note: When using the correction needle, other yarns cannot be picked off , when the broken yarn is picked out, there should be no remaining yarn), after picking out the protruding yarn in the middle, use the correction needle to evenly dial the weft yarns adjacent to the weft yarn, and finally use the electronic grade glass fiber cloth 1 larger than the electronic grade fiberglass cloth to be modified 7628 cloth kinds of modified wiping cloth (basis weight 210g) with ...

Embodiment 2

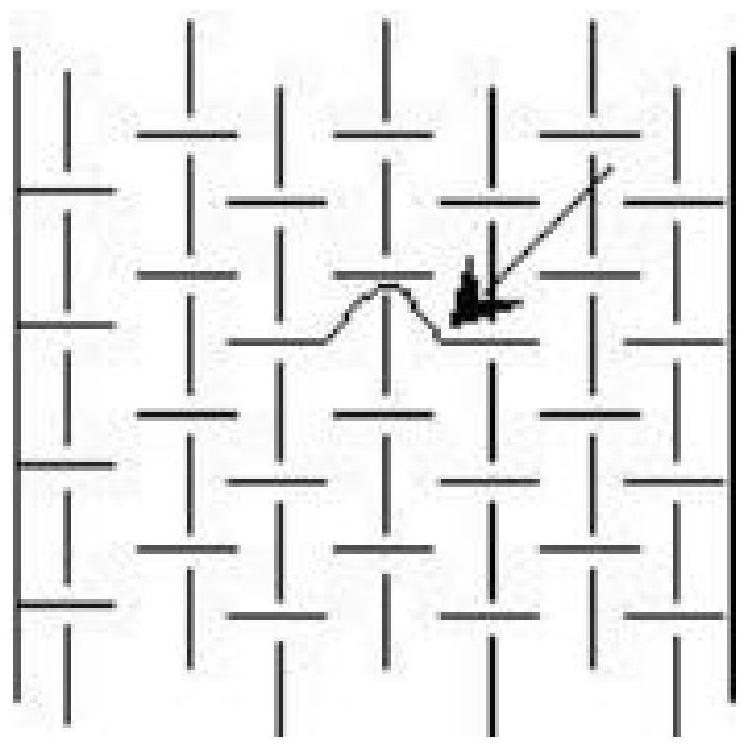

[0035] For the abnormal item of electronic grade glass fiber cloth loose loop weft, the staff first records the meter length of the defect detected by CCD before inspection, and finds the wavy weft yarn on the surface of the electronic grade glass fiber cloth to be modified according to the defect meter length detected by CCD , and then use the combined force of the thumb and forefinger to pull out the wavy weft yarn. The occurrence rate of loose loop weft defects on the finished fabric surface to downstream customers is 2%.

Embodiment 3

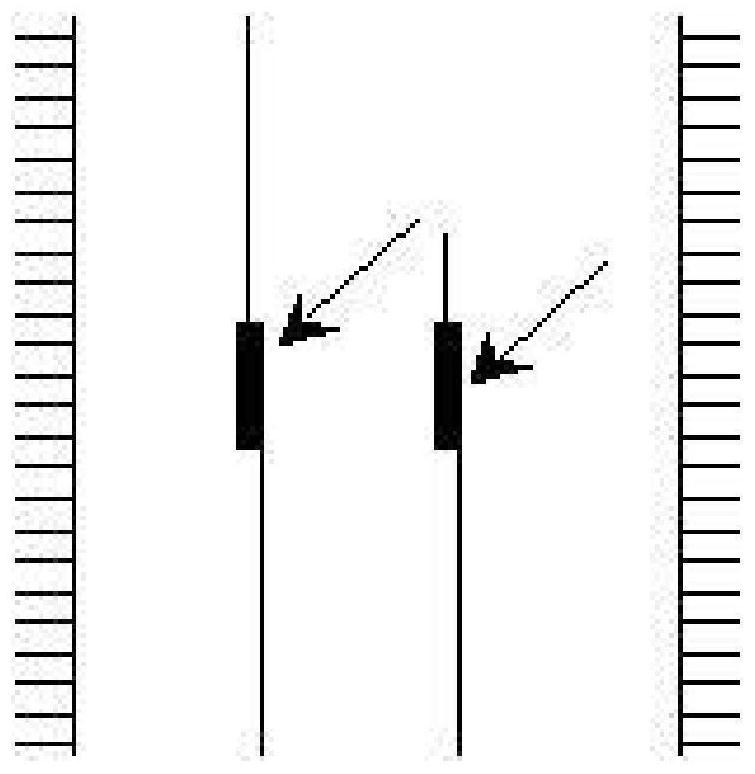

[0037]For 1080 types of cloth (basis weight 48g) electronic grade glass fiber cloth with loose loops and weft abnormal items, the staff first records the meter length of the defect detected by the CCD before inspection, and finds the electronic grade glass to be modified according to the defect meter length detected by the CCD For the loose weft on the surface of the fiber cloth, use the correction scissors to cut off the protruding loose weft on the surface, and finally use a modified wiping cloth 2116 cloth type (basis weight 104g) Wipe the cloth surface of the modified electronic-grade glass fiber cloth to make it smooth, and the occurrence rate of loose loop weft defects on the cloth surface of the finished cloth to downstream customers is 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com