Self-resetting steel support with pre-pressing disc spring and friction damper

A friction damper and self-resetting technology, which is applied to building components, earthquake resistance, building types, etc., can solve problems such as high manufacturing precision requirements and complex steel support structures, and achieve reduced repair costs, reduced residual deformation, and a better society benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

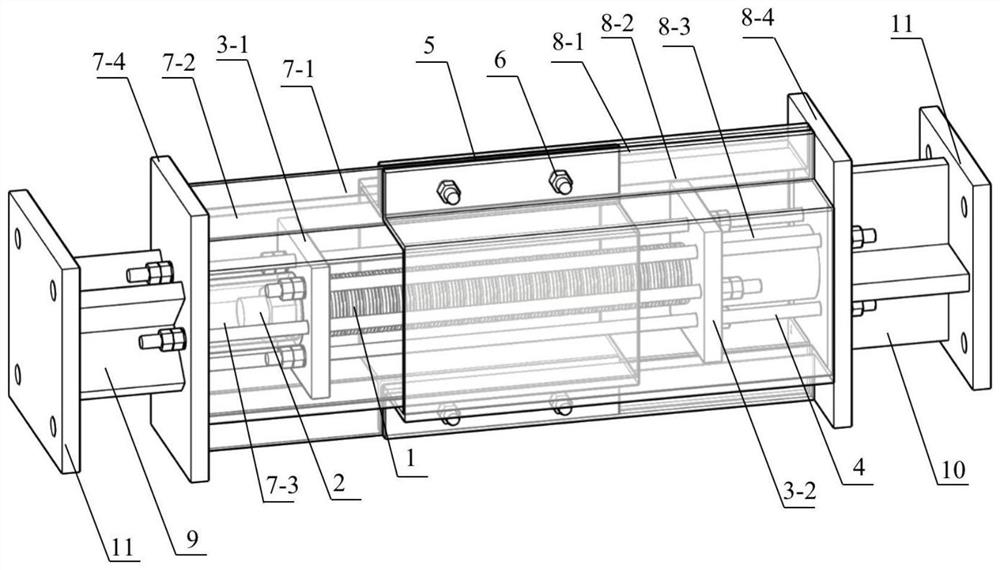

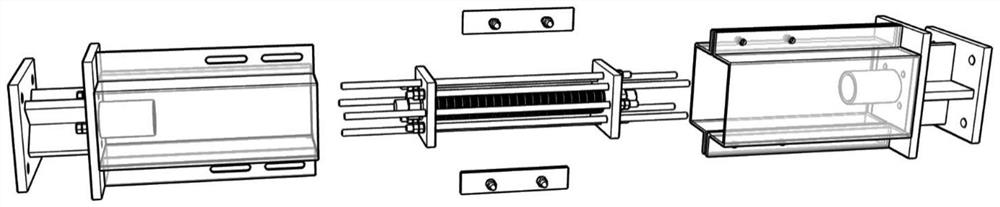

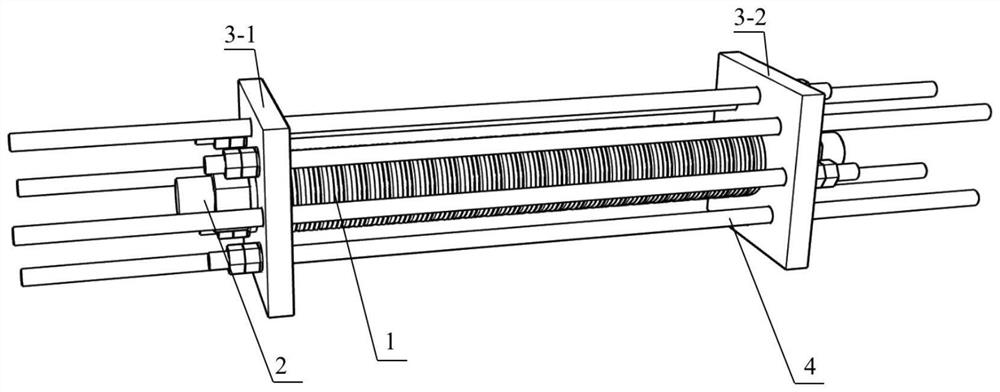

[0034] The present invention is a self-resetting steel support with a preloaded disc spring and a friction damper, including a reset system and a frictional energy dissipation system, wherein a disc spring is used as a reset element, and the combined disc spring, anchor plate and anchor bolt are connected in series through a screw to form Compression spring return system, different combination methods can be used to obtain different denaturation characteristic curves, can withstand large loads with small deformation, and there is no residual deformation after repeated loading; the reset system is reset by high-strength bolts with a diameter of 20mm It is connected with the frictional energy dissipation system to form the self-resetting energy dissipation support. And the friction energy dissipation device is set outside the support, and the fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com