Light, high-power and particle-rich gunpowder ignition device

An ignition device and high-power technology, applied in the direction of rocket engine devices, jet propulsion devices, machines/engines, etc., can solve the problems of poor ignition capability, high cost, complicated design and production, etc., to increase effectiveness and reliability, Effects of weight reduction and mass ratio improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

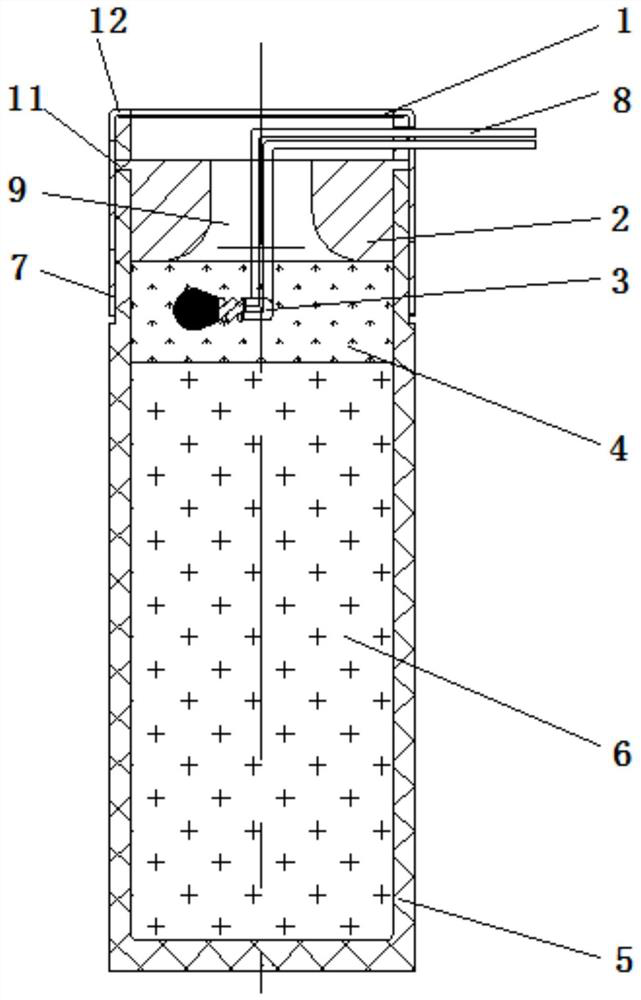

[0037] figure 1 A structure of an ignition device is disclosed, including an ignition head 3 (including an ignition lead 8), an initial charge 4, a main charge 6, a casing, a nozzle 2 and a sealing diaphragm 1;

[0038] One end of the shell is an ignition port, and a sealing diaphragm 1 is installed at the ignition port;

[0039] A nozzle 2, an initial charge 4 and a main charge 6 are sequentially arranged in the shell from the ignition port inward;

[0040] The ignition head 3 is arranged inside the starting charge 4, and its ignition lead wire 8 is drawn out of the shell;

[0041] The nozzle pipe 2 is provided with a nozzle hole 9 along the center; the diameter of the nozzle hole 9 gradually increases from the ignition port to the inside. The method in this embodiment is to form a straight hole near the nozzle hole of the sealing diaphragm, and the nozzle hole near the initial charge is trumpet-shaped, and the largest end of the trumpet shape is close to the described prim...

Embodiment 2

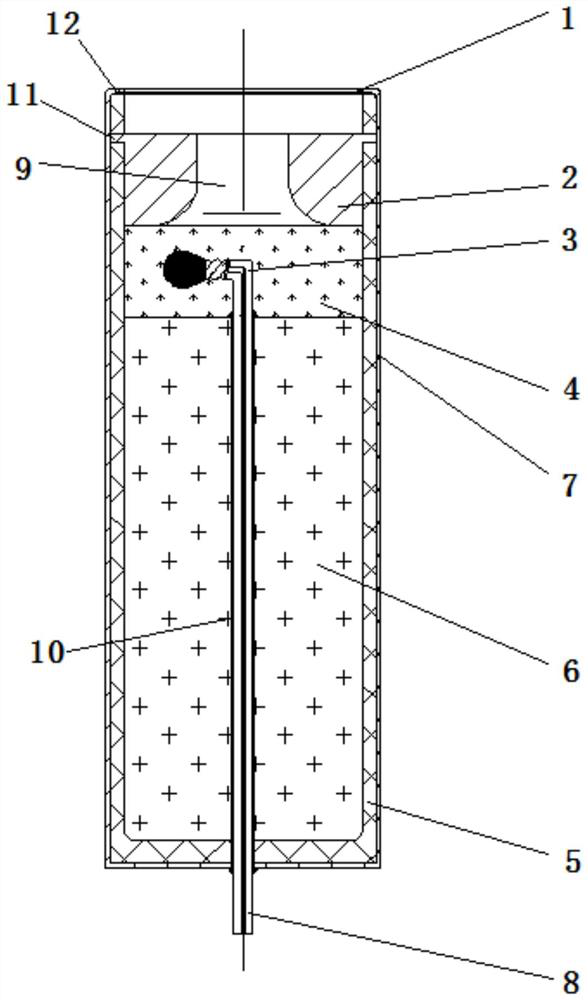

[0050] figure 2 The structure of another ignition device is disclosed, including an ignition head 3 (including an ignition lead 8), an initial charge 4, a main charge 6, a shell, a nozzle 2 and a sealing diaphragm 1;

[0051] One end of the shell is an ignition port, and a sealing diaphragm 1 is installed at the ignition port;

[0052] A nozzle 2, an initial charge 4 and a main charge 6 are sequentially arranged in the shell from the ignition port inward;

[0053] The ignition head 3 is arranged inside the starting charge 4, and its ignition lead wire 8 is drawn out of the shell;

[0054] The nozzle pipe 2 is provided with a nozzle hole 9 along the center; the diameter of the nozzle hole 9 gradually increases from the ignition port to the inside. The method in this embodiment is to form a straight hole near the nozzle hole of the sealing diaphragm, and the nozzle hole near the initial charge is trumpet-shaped, and the largest end of the trumpet shape is close to the initial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com