Sewage treatment heater

A technology for sewage treatment and heaters, applied in heating water/sewage treatment, heat storage heaters, fluid heaters, etc., can solve problems such as pipe bursting, reducing thermal efficiency, and difficulty in dissipating heat from heaters, so as to avoid pipe bursting. , The effect of increasing the heating area and reducing the maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

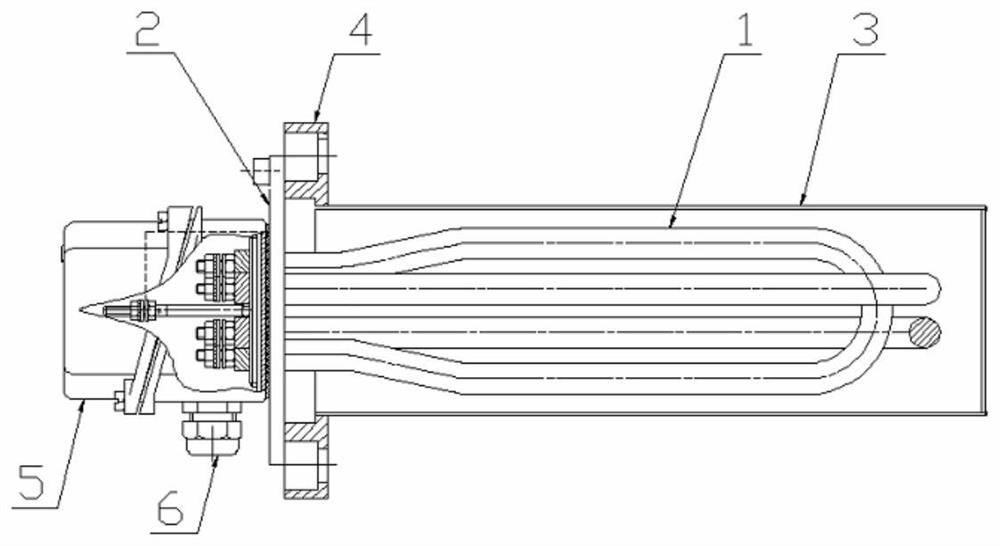

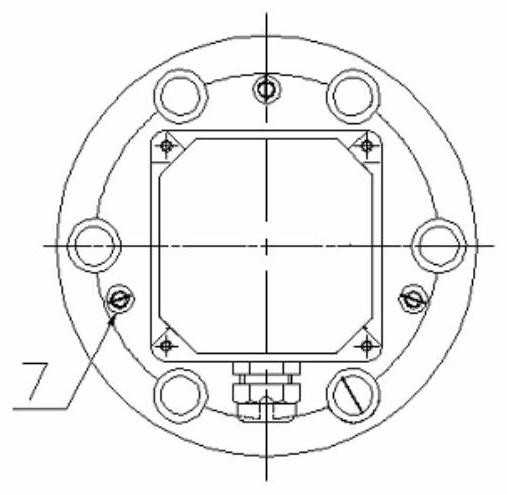

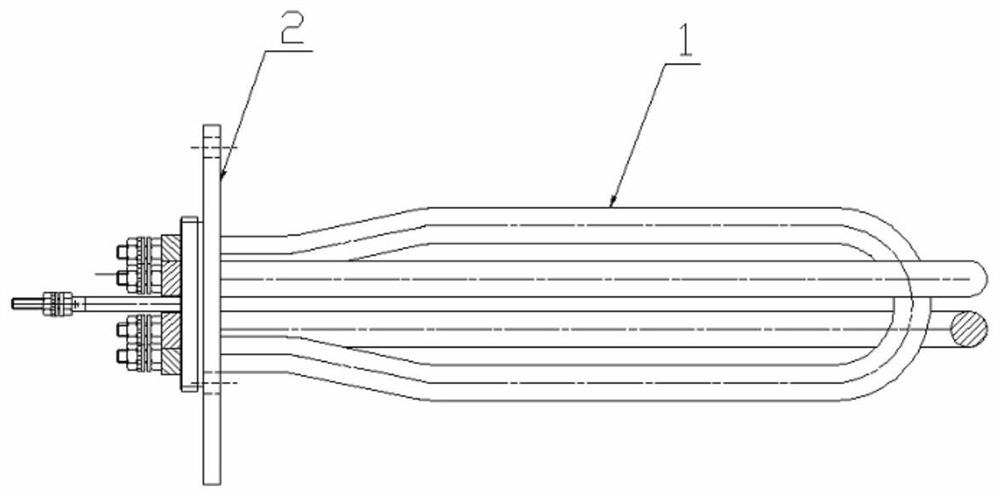

[0026] Such as figure 1 , 2 As shown, a sewage treatment heater includes a heating element. It also includes a small flange, a large flange 4 and a closing sleeve 3. The heating element includes a heating tube 1, such as Figure 3-6 As shown, the heating tube 1 is a U-shaped or 3U-shaped heating tube. The end of the heating tube 1 is welded on the small flange 2 .

[0027] Such as Figure 7 , 8 As shown, the sleeve 3 is arranged on the large flange 4 by argon arc welding, the sleeve 3 must be airtight, and can withstand at least 6bar pressure. The heating element is arranged in the sleeve 3, and the sleeve 3 is filled with a heat transfer medium. The heating pipe 1 passes through the heat transfer medium such as air or heat transfer oil inside the heating sleeve 3, and then transfers the heat to the sleeve 3, and the sleeve 3 effectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com