Path planning method and system for foot type inspection robot of transformer substation

An inspection robot and path planning technology, which is applied to control/adjustment systems, instruments, motor vehicles, etc., can solve the problems of obtaining inspection data, inspection, planning path restrictions, etc., to reduce inspection time and improve inspection time. Efficiency, the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

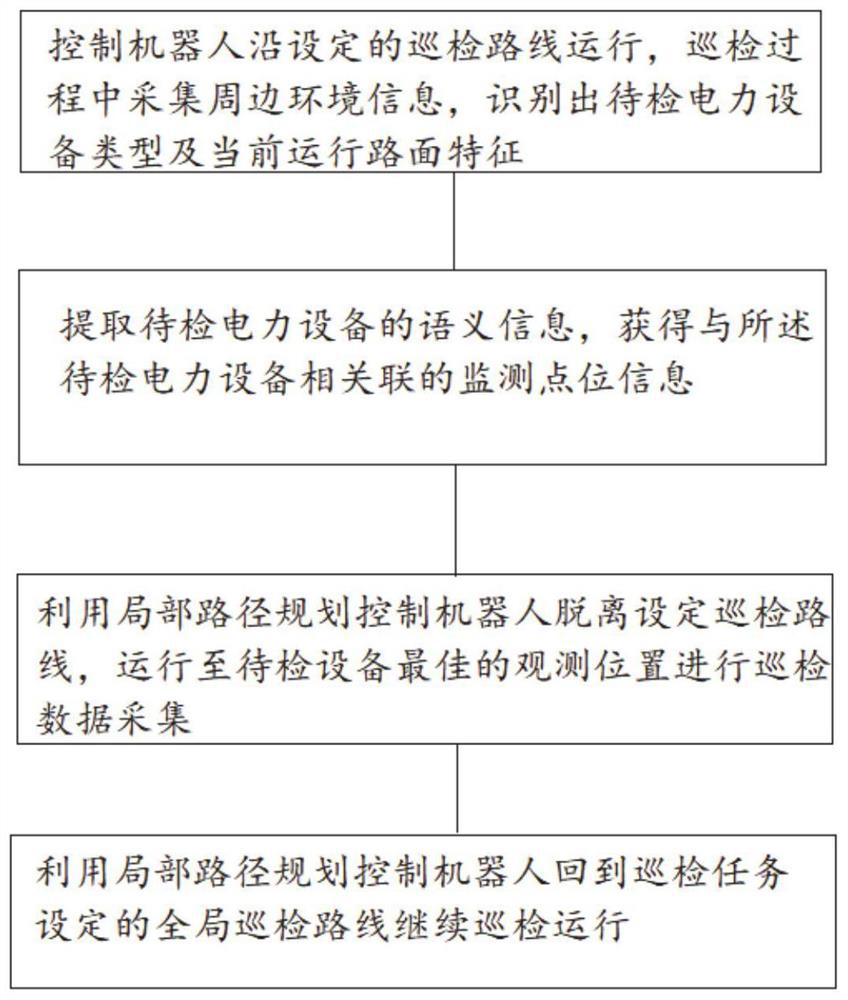

[0041] According to an embodiment of the present invention, an embodiment of a path planning method for a substation legged inspection robot is provided, refer to figure 1 , including the following procedures:

[0042] S101: Control the robot to run along the set inspection route, collect surrounding environmental information during the inspection process, and identify the type of electrical equipment to be inspected and the characteristics of the current operating road surface;

[0043] Specifically, the robot receives the inspection task and navigates along the global inspection route set by the inspection task; during the operation of the robot, it uses sensors such as vision sensors or lidar to collect the surrounding environmental information of the robot, and uses deep learning or other pattern recognition technologies Identify the type of electrical equipment to be inspected, extract the semantic information of the electrical equipment to be inspected, and the character...

Embodiment 2

[0079] According to an embodiment of the present invention, an embodiment of a substation legged inspection robot path planning system is provided, which specifically includes:

[0080] The information collection module is used to control the robot to run along the set inspection route, collect surrounding environmental information during the inspection process, and identify the type of power equipment to be inspected and the characteristics of the current operating road surface;

[0081] An information extraction module, configured to extract semantic information of the power equipment to be checked, and obtain monitoring point information associated with the power equipment to be checked;

[0082] The local path planning module is used to use local path planning to control the robot to run away from the set inspection route to the best observation position of the equipment to be inspected for inspection data collection based on the relative positional relationship between the...

Embodiment 3

[0086] In one or more embodiments, a substation footed inspection robot is disclosed, including the substation footed inspection robot path planning system described in the second embodiment, or using the substation footed inspection robot described in the first embodiment The inspection robot path planning method carries out the inspection of electric equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com