Real-time prediction method for engine emission

A real-time prediction and engine technology, which is applied in the direction of engine testing, internal combustion engine testing, neural learning methods, etc., can solve the problems of not reflecting the engine's transient emission performance well, long calculation time, expensive instrument purchase and maintenance costs, etc. , to achieve the effect of improving the efficiency of the algorithm, accurate prediction results, and avoiding limited generalization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

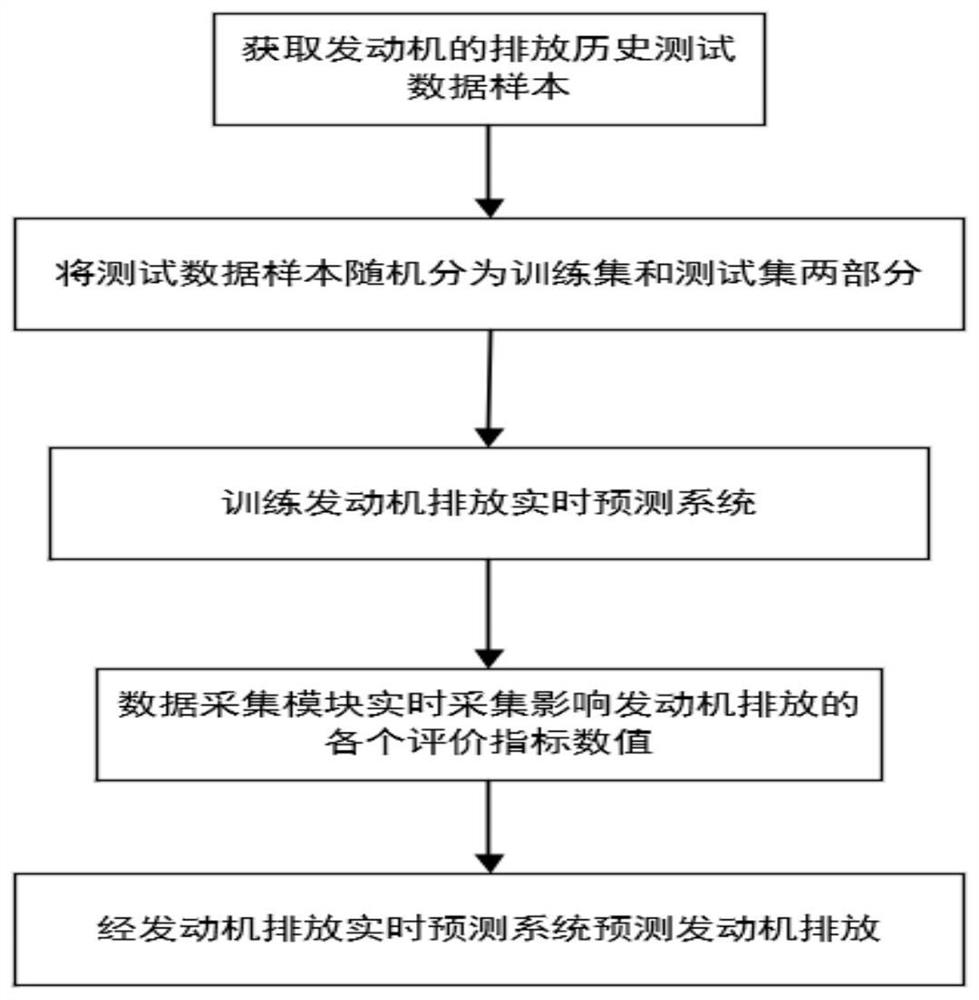

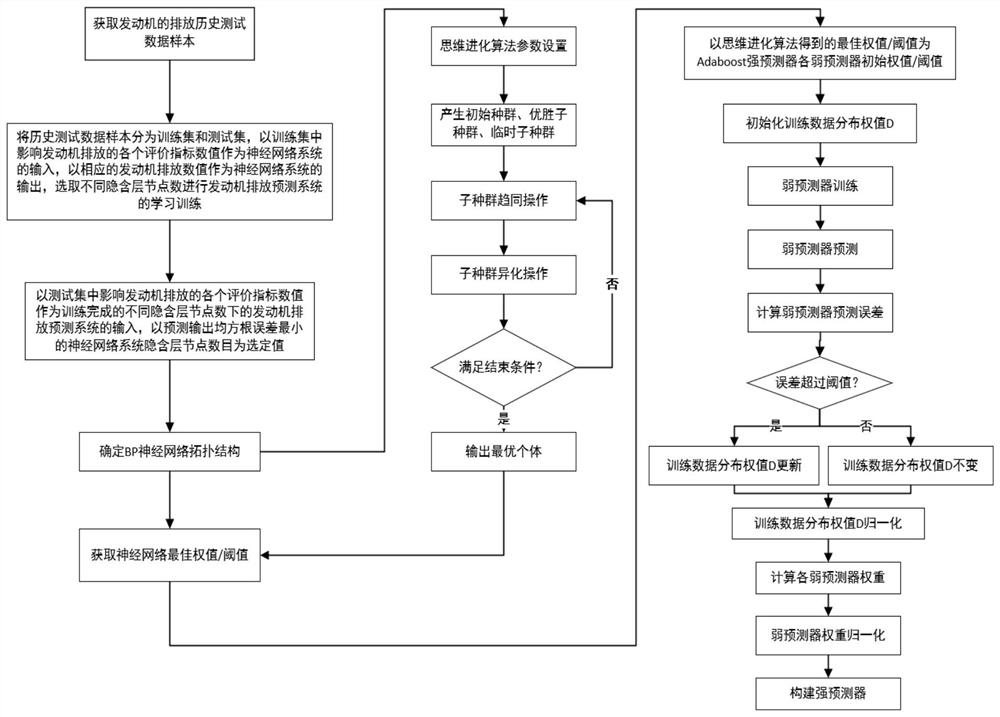

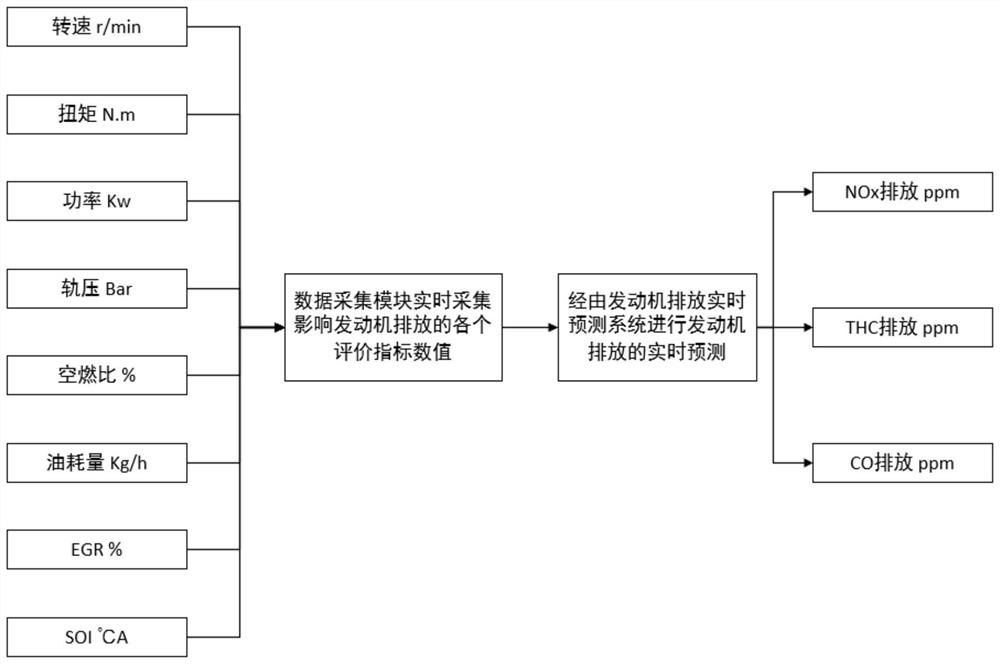

[0084] As an embodiment of the present invention, the specific steps are:

[0085] Step 4021, define the individual score function of each winning subpopulation and temporary subpopulation, the steps are:

[0086] First, each individual in each winning subpopulation and temporary subpopulation is decoded to obtain the neural network connection weight matrix and threshold matrix corresponding to each individual. The steps are:

[0087] Transform the first to p*g elements of each subpopulation into the first connection weight matrix w in the order of columns p×g , that is, the first column of the matrix is filled first, and then the other columns are filled in turn, each element in the first connection weight matrix and the connection weight from the input layer neuron to the hidden layer neuron in the step 3 value w ks Consistent; transform the p*g+1th element to the p*g+g*hth element of the individual into the second connection weight matrix w in the order of columns g×h ...

Embodiment

[0117] Select 100 groups of engine emission history test data samples, randomly select 90 groups of samples to train the prediction model adopted in the engine emission real-time prediction method proposed by the present invention, and use the remaining 10 groups of samples as a test set to check the accuracy of the method of the present invention ,get:

[0118] 1. The NOx emission prediction effect of the engine emission real-time prediction method proposed by the present invention and the neural network without any optimization and only through the initial weight threshold optimization is shown in the figure Figure 5 shown;

[0119] 2. The real-time prediction method of engine emission proposed by the present invention is compared with the relative error of the NOx emission prediction value of the neural network without any optimization and only through the initial weight threshold optimization. Image 6 shown;

[0120] 3. The comparison of the THC emission prediction eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com