Variable-stiffness end effector based on wedge-shaped bristle bundles

An end effector and variable stiffness technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of asymmetric contact area between two units, difficulty in providing reliable loading, and inability to guarantee the flatness of bristle bundles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

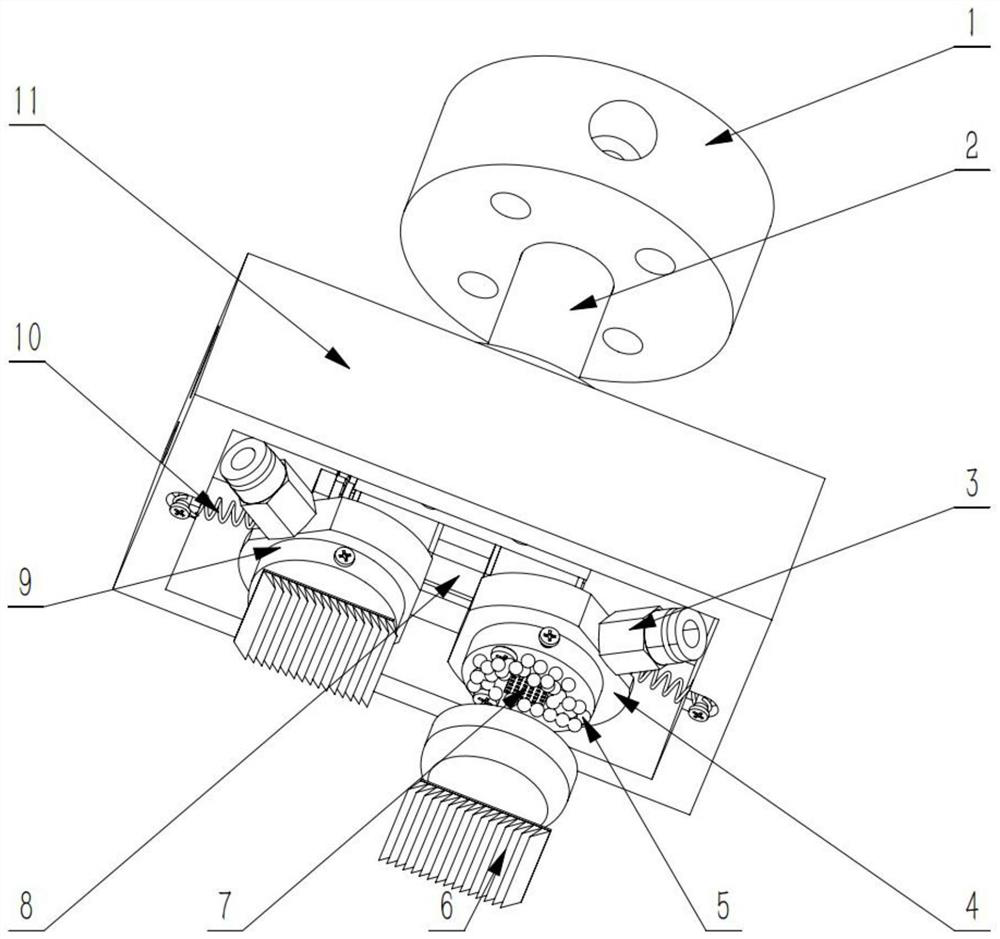

Embodiment 1

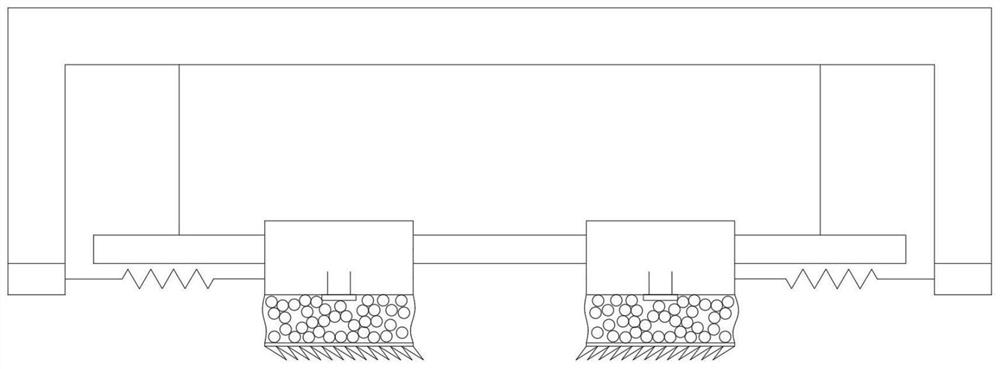

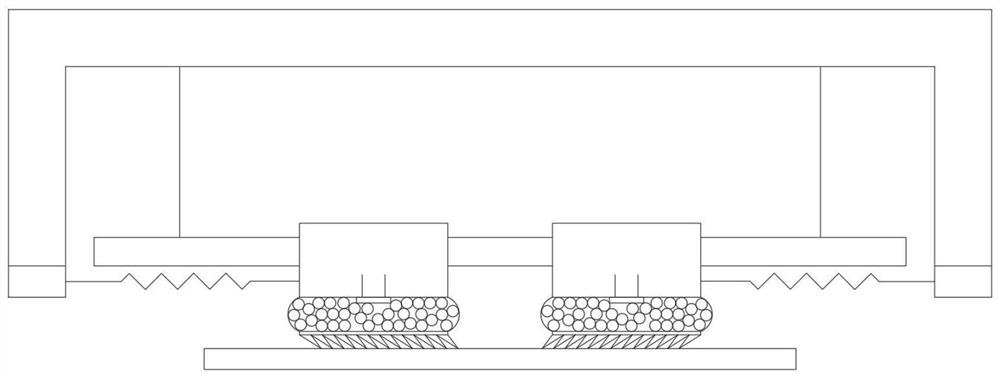

[0037] Such as Figure 1-6 As shown, this embodiment provides a variable stiffness end effector based on wedge-shaped bristle bundles. The stiffness of the base of the wedge-shaped bristle bundles is changed through a soft bag 9 combined with particles 5, and a tangential load is applied through a tension spring 10; based on wedge-shaped bristle bundles The variable stiffness end effector of the beam mainly includes five units-wedge-shaped bristle bundle unit 6, tangentially loaded detachment unit, variable stiffness unit, driving device and outer frame unit. In this embodiment, the above five units coordinate with each other to realize the end effector The function of the actuator to adhere to the planar target.

[0038] Specifically, the outer frame unit includes an outer frame 11, and the outer frame 11 is used to maintain the relative positions of the various components in the end effector and to connect with the external connection mechanism; wherein, the external connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com