Lithium ion battery positive electrode slurry and preparation method thereof

A lithium-ion battery and positive electrode slurry technology, which is applied in the direction of battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of high surface tension, difficult processing, and shrinkage of slurry, so as to reduce surface tension and facilitate dispersion , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

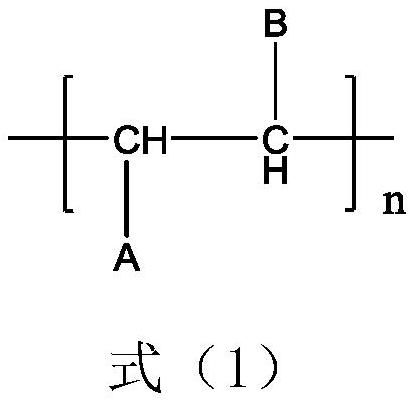

[0027]A lithium ion battery positive slurry comprising a positive electrode active substance, a binder, a conductive agent, a stabilizer, and a solvent, and the structural formula of the stabilizer is shown in the formula (1):

[0028]

[0029]In the formula (1), the A group is -Cho, the B group is -C2Hide5. The molecular weight of the stabilizer is 850,000.

[0030]Among them, the mass ratio of the positive active substance, the binder, the conductive agent, and the stabilizer is 97.5: 1: 1: 0.5, and the positive active substance is Li (Ni0.8CO0.1Mn0.1) O2The secondary ball, the binder is polyvinylidene fluoride, the conductive agent is superconducting carbon black, the solvent is NMP; the solid content of the positive electrode slurry is 75%.

[0031]The preparation method of the above lithium-ion battery positive pole slurry includes the following steps:

[0032]S1, dissolve polyvinylidene fluoride in NMP to obtain a polyvinylidene fluoride solution having an solid content of 8%, and disperse t...

Embodiment 2

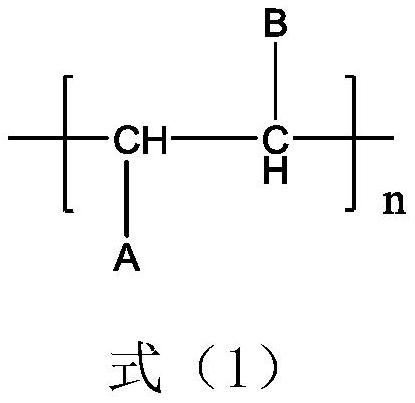

[0044]A lithium ion battery positive slurry comprising a positive electrode active substance, a binder, a conductive agent, a stabilizer, and a solvent, and the structural formula of the stabilizer is shown in the formula (1):

[0045]

[0046]In the formula (1), the A group is -NH2, B group is -c6Hide5. The molecular weight of the stabilizer is 1.1 million.

[0047]Among them, the mass ratio of the positive active substance, the binder, the conductive agent, and the stabilizer is 97.8: 1: 1: 0.2, the positive electrode active material is Li (Ni0.5CO0.2Mn0.3) O2The single crystal particles, the adhesive is polyvinylidene fluoride, the conductive agent is a single-walled carbon nanotube, the solvent is NMP; the solid content of the positive electrode slurry is 65%.

[0048]The preparation method of the above lithium-ion battery positive pole slurry includes the following steps:

[0049]S1, dissolve polyfial fluoride is dissolved in NMP to obtain a polyvinylidene fluoride solution having a solid con...

Embodiment 3

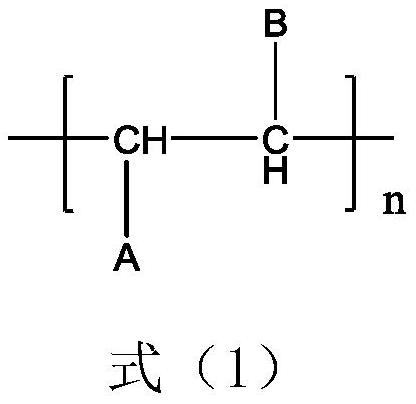

[0061]A lithium ion battery positive slurry comprising a positive electrode active substance, a binder, a conductive agent, a stabilizer, and a solvent, and the structural formula of the stabilizer is shown in the formula (1):

[0062]

[0063]In the formula (1), a group is -COOH, B group is -c6Hide5. The molecular weight of the stabilizer is 1 million.

[0064]Among them, the mass ratio of the positive active substance, the binder, the conductive agent, and the stabilizer are 97.2: 1: 0.8: 1, the positive active substance is Li (Ni0.88CO0.07Mn0.05) O2The single crystal particles, the adhesive is polyvinylidene fluoride, the conductive agent is a multi-walled carbon nanotube, the solvent is NMP; the solid content of the positive electrode slurry is 78%.

[0065]The preparation method of the above lithium-ion battery positive pole slurry includes the following steps:

[0066]S1, dissolve polyfial fluoride in the solvent to obtain a polyvinylidene fluoride solution having a solid content of 10%, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com