A method for improving the stability of high-calcium milk by optimizing the production process

A production process and stability technology, applied in the field of milk powder processing, can solve problems such as poor dispersion stability, and achieve the effects of high practicability and improved dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

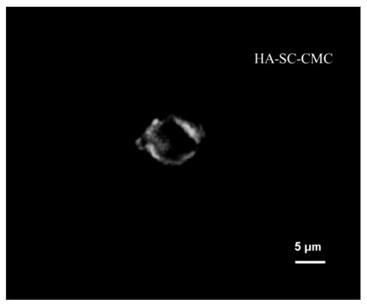

[0026] A method for improving the dispersion stability of hydroxyapatite by preparing a polysaccharide-protein-calcium salt compound using sodium caseinate, hydroxyapatite and sodium carboxymethylcellulose as raw materials, the specific process steps are as follows:

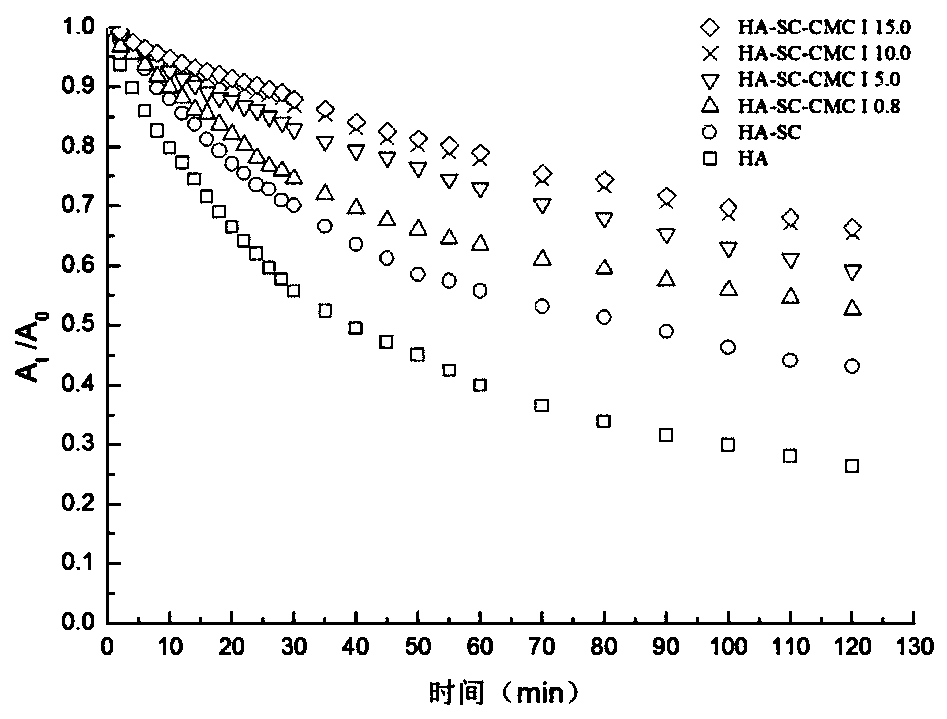

[0027] Weigh 20 mg of HA-SC complex, add a small amount of ultrapure water to disperse it evenly, and then add CMC solution, so that 0.2 mg–15.0 mg of CMC I (molecular weight: 250,000, substitution degree: 0.9) in the final 10 mL reaction system, mix Evenly, adjust the pH to 4.0 with hydrochloric acid, rotate for 4 hours, centrifuge at 4000rpm for 10min, redisperse the precipitate in 10mL ultrapure water, oscillate, and centrifuge again at 4000rpm for 10min to obtain the precipitate that is the washed HA-SC-CMC I Complex. With the increase of CMC addition, more CMC is adsorbed on the surface of HA-SC, and the surface has more negative charges, the electrostatic mutual repulsion between particles and the steric hi...

Embodiment example 2

[0029] Weigh 20 mg of HA-SC complex, add a small amount of ultrapure water to disperse it evenly, and then add CMC solution, so that the CMC II (molecular weight is 700,000, substitution degree is 0.9) in the final 10 mL reaction system is 0.2 mg–15.0 mg, The specific operation steps are the same as the implementation case 1, and finally the HA-SC-CMC II complex is obtained. With the increase of CMC addition, more CMC II is adsorbed on the surface of HA-SC, and the surface has more negative charges, the electrostatic mutual repulsion between particles and the steric hindrance of polysaccharide chains are enhanced, so that HA-SC -The stability of the redispersion suspension of the CMC II complex is improved ( Figure 5 ).

Embodiment example 3

[0031] Weigh 20 mg of HA-SC complex, add a small amount of ultrapure water to disperse it evenly, and then add CMC solution, so that the CMC II (molecular weight is 250,000, substitution degree is 0.7) in the final 10 mL reaction system is 0.2 mg–15.0 mg, The specific operation steps are the same as the implementation case 1, and finally the HA-SC-CMC III complex is obtained. With the increase of the amount of CMC added, more CMC was adsorbed on the surface of HA-SC, and the surface had more negative charges, and the stability of the HA-SC-CMC III complex redispersed suspension was improved ( Image 6 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com