Sewage suction pipe inner wall cleaning device

A technology for cleaning inner walls and sewage pipes, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

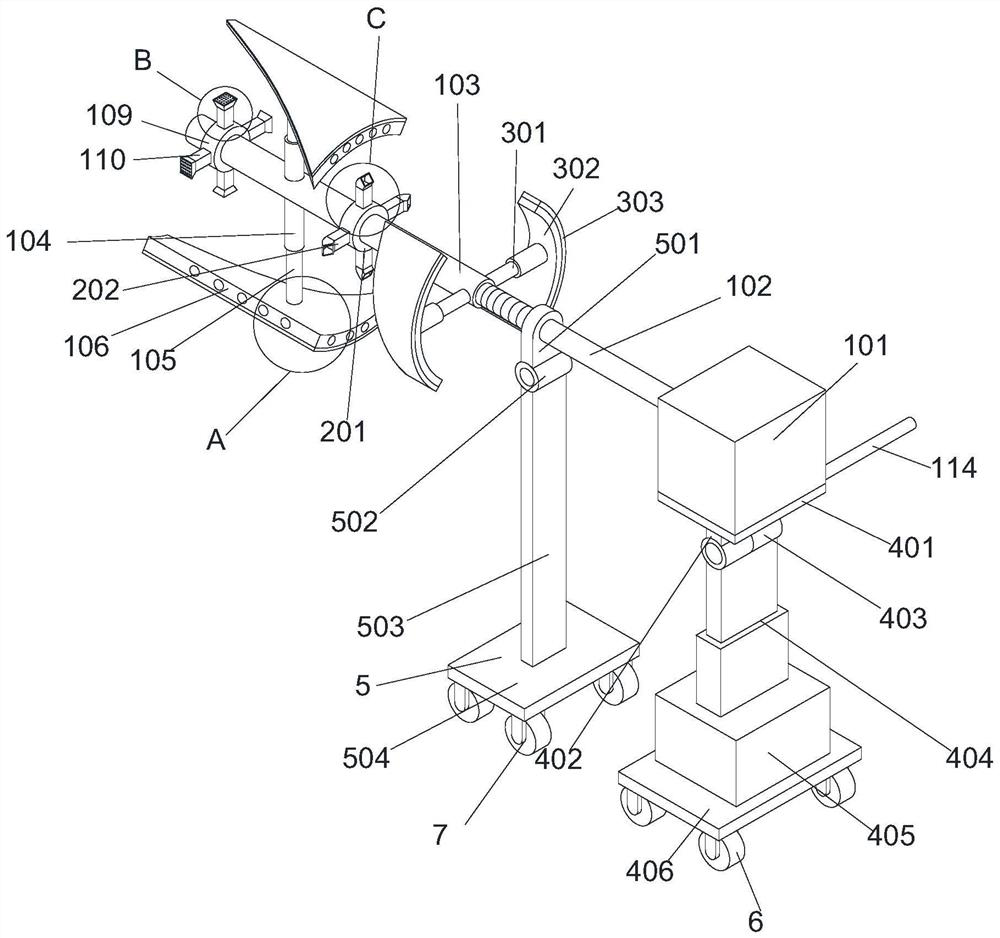

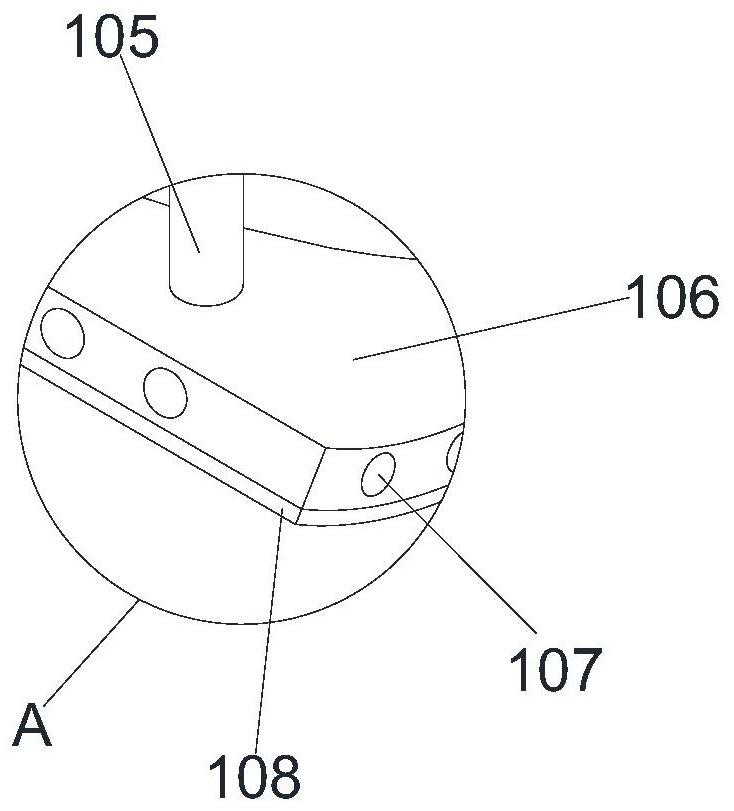

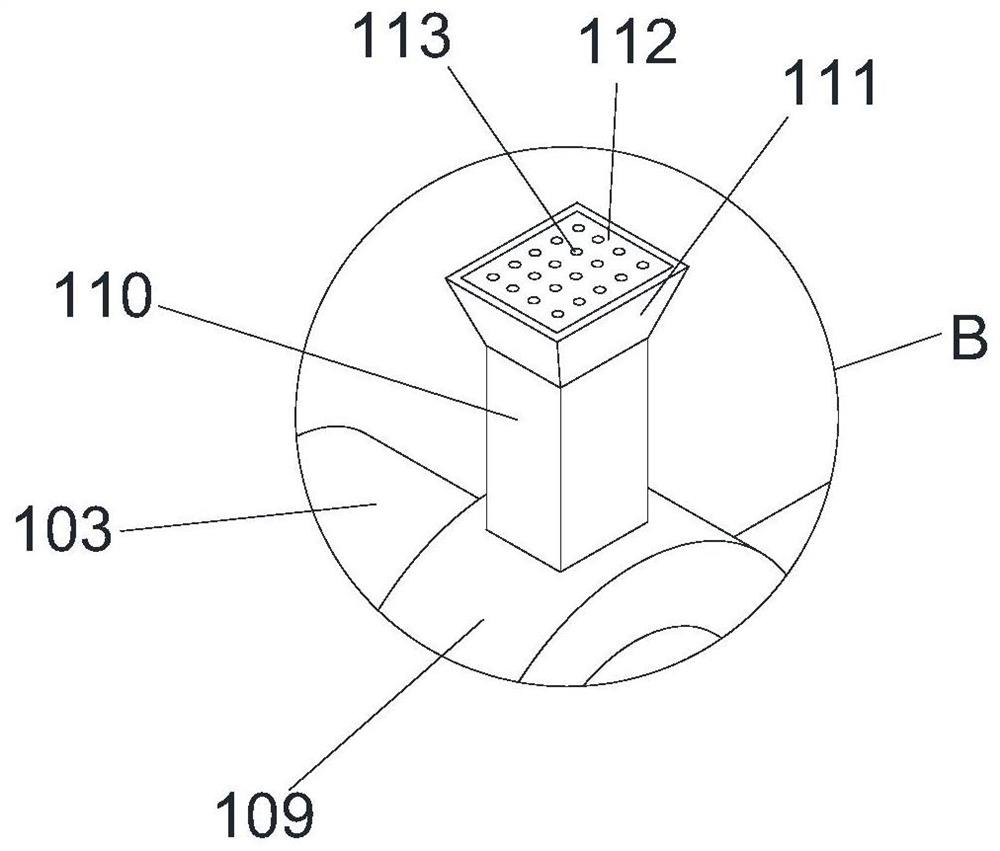

[0023] Example 1: Please refer to figure 1 , figure 2 and image 3 , the present invention provides the following technical solutions: a device for cleaning the inner wall of a sewage suction pipe, comprising a water pump 101, a drain pipe 102 is fixedly connected to the center of the rear side of the water pump 101, and a thread is provided at the rear end of the circumferential surface of the drain pipe 102 to drain water. The thread surface of pipe one 102 is threadedly connected with drain pipe two 103, the lower end of the circumference side of drain pipe two 103 is fixedly connected with sleeve pipe 104, and the lower end of the inner wall of sleeve pipe 104 is slidably connected with slide pipe 105, and inside the sleeve pipe 104 and slide pipe 105 A spring is provided, and the lower surface of the sliding pipe 105 is fixedly connected with a scraper one 106, and the lower surface of the scraper one 106 is fixedly connected with a cleaning cushion one 108, and the cir...

Embodiment 2

[0025] Example 2: Please refer to figure 1 and Figure 4 , on the basis of Embodiment 1, the circumferential side of the drainpipe 2 103 is provided with an opening and the water passage ring 2 201 is fixedly sleeved at the opening, and the circumferential side of the water passage ring 201 is fixedly connected with the water passage pipe 2 202 , the upper surface of the second water pipe 202 is fixedly connected with an elbow 203 , and the second water ring 201 is located at the front side of the casing 104 .

[0026] When in use, the cleaning pad-108 rotates to scrape off the dirt on the inner wall of the suction pipe to separate the dirt. When detached, the dirt may fall and splash onto the front side pipe wall of the cleaning pad-108. At this time, the cleaning cushion 1 108 can no longer clean the sputtered part. Set the water ring 201, the water pipe 202 and the elbow 203 and the water ring 201 is located at the front side of the casing 104, and the clean water passes t...

Embodiment 3

[0027] Example 3: Please refer to figure 1 , figure 2 and Figure 5 , on the basis of the second embodiment, the front end of the circumferential side of the drainage pipe 2 103 is fixedly connected with a spring telescopic rod 301, and the right side of the spring telescopic rod 301 is fixedly connected with a scraper 2 302, and the right side of the scraper 2 302 is fixed. Connected with cleaning pad 2 303, spring telescopic rod 301, scraper 2 302 and cleaning pad 2 303 are symmetrically arranged around the center of the drainage pipe 2 103 as the axis, and the front side and left side of scraper 1 106 run through. There are through grooves 107, and the through grooves 107 are arranged in an arc along the inside of the first scraper 106, and the cross-sectional shape of the second scraper 302 is a right-angled trapezoid.

[0028] When in use, the rotation of the drain pipe 2 103 stretches the spring telescopic rod 301 through centrifugal force, and the cleaning cushion 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com