Milling cutter clamp and milling cutter of numerical control milling machine

A milling cutter fixture and CNC milling machine technology, which is applied in the field of machining, can solve the problems of not having the self-monitoring capability of the rotation state of the milling cutter, and the inability to realize the clamping and fixing of the milling cutter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

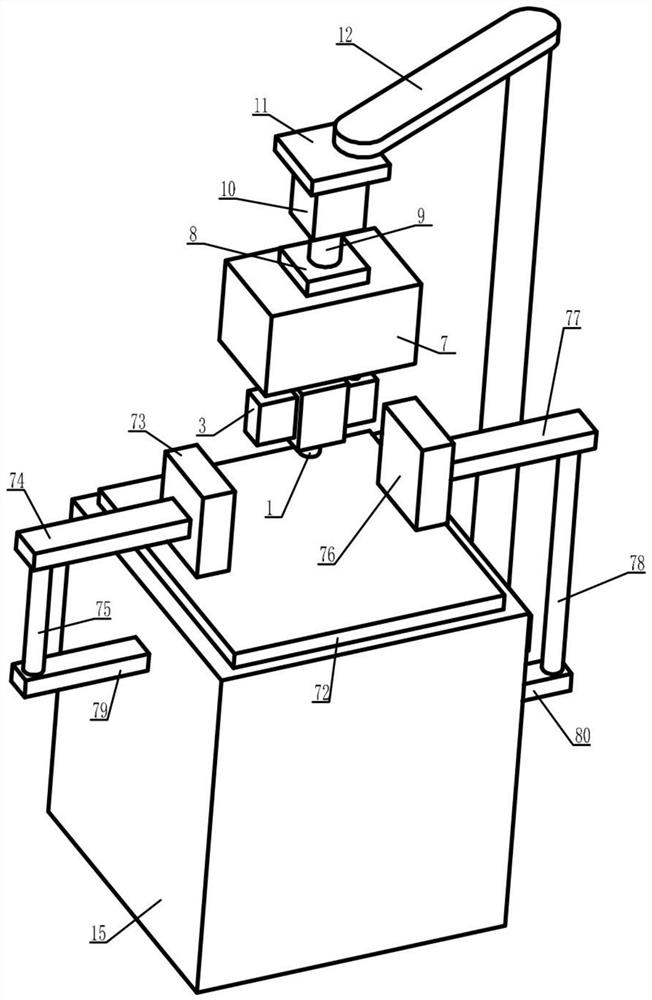

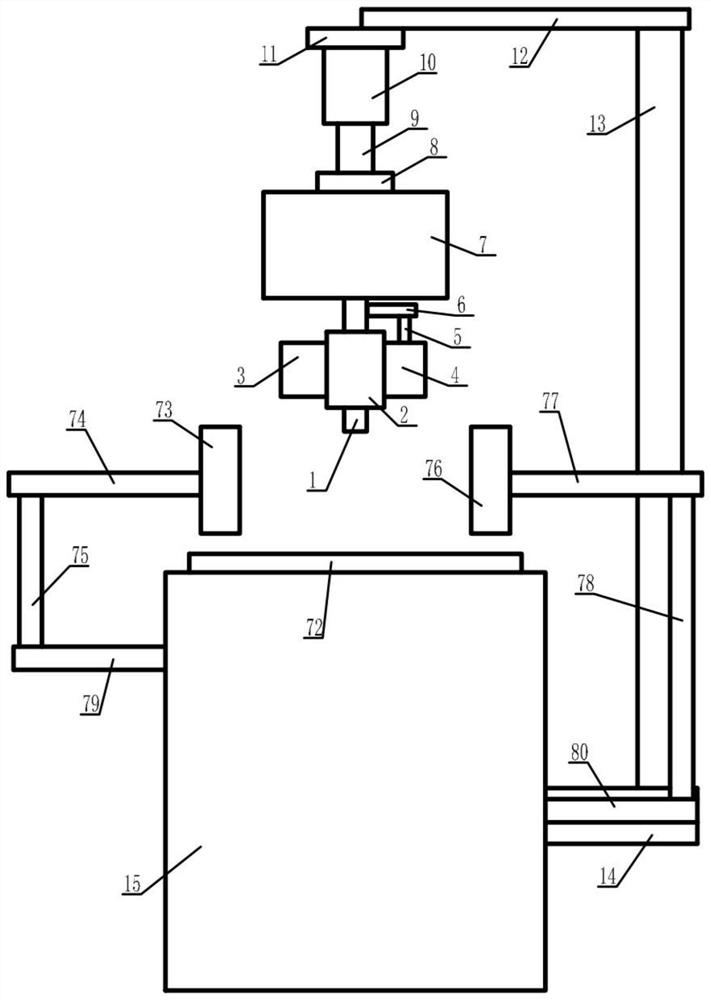

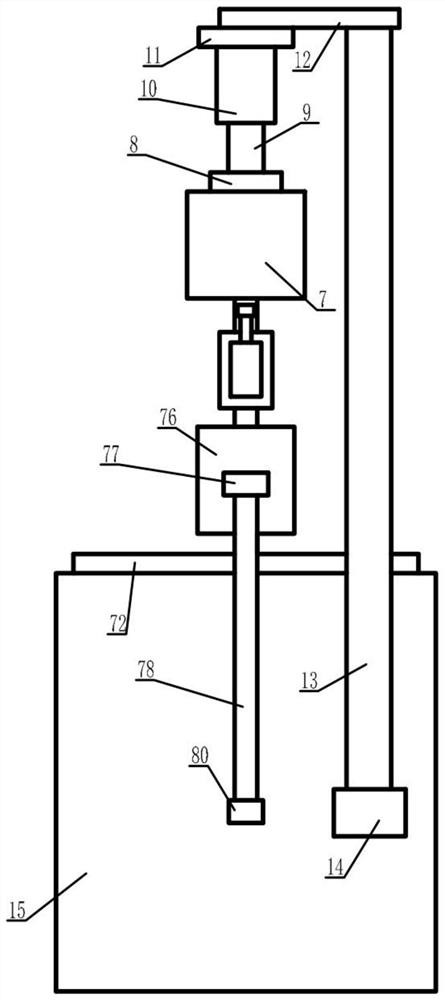

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

[0031] refer to Figure 1 to Figure 10 , the milling cutter fixture and milling cutter of a kind of numerical control milling machine provided by the present invention comprise milling cutter 1, the lower periphery of described milling cutter 1 is provided with square sleeve 2, and the left side of described square sleeve 2 is provided with There is a rotation sensor 3, and the right side of the square sleeve 2 is provided with a liquid outlet 4, and the top end of the milling cutter 1 extends into the inside of the milling cutter clamping box 7, and the milling cutter clamping box 7 The top surface of the tight box 7 is fixed with an intermediate connection plate 8, the top surface of the intermediate connection plate 8 is fixedly connected with the bottom end of the first power shaft 9, and the first power shaft 9 is arranged on the bottom of the first engine 10. The lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com