Method for synthesizing TS-1 zeolite through size-adjustable solvent-free method

A TS-1, solvent-free technology, applied in chemical instruments and methods, inorganic chemistry, molecular sieve compounds, etc., can solve the problems of zeolite size control difficulties, etc., and achieve the effects of reducing water pollution, complete crystal morphology, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Put 0.60g of fumed silica and 0.81g of tetrapropylammonium hydroxide containing 0.61g of water in a mortar and grind to a particle size of 0.5 μm, then add 0.015g of pure silicalite seed crystals with an average particle size of 500nm and sulfuric acid Continue to grind 0.024g of titanium until the particle size is 0.3 μm, and then place it in a reactor for crystallization. The reaction temperature is 180°C, and the reaction time is 24h. The obtained product is suction-filtered, baked at 60°C for 24h, and calcined at 550°C for 6h to obtain TS-1 zeolite;

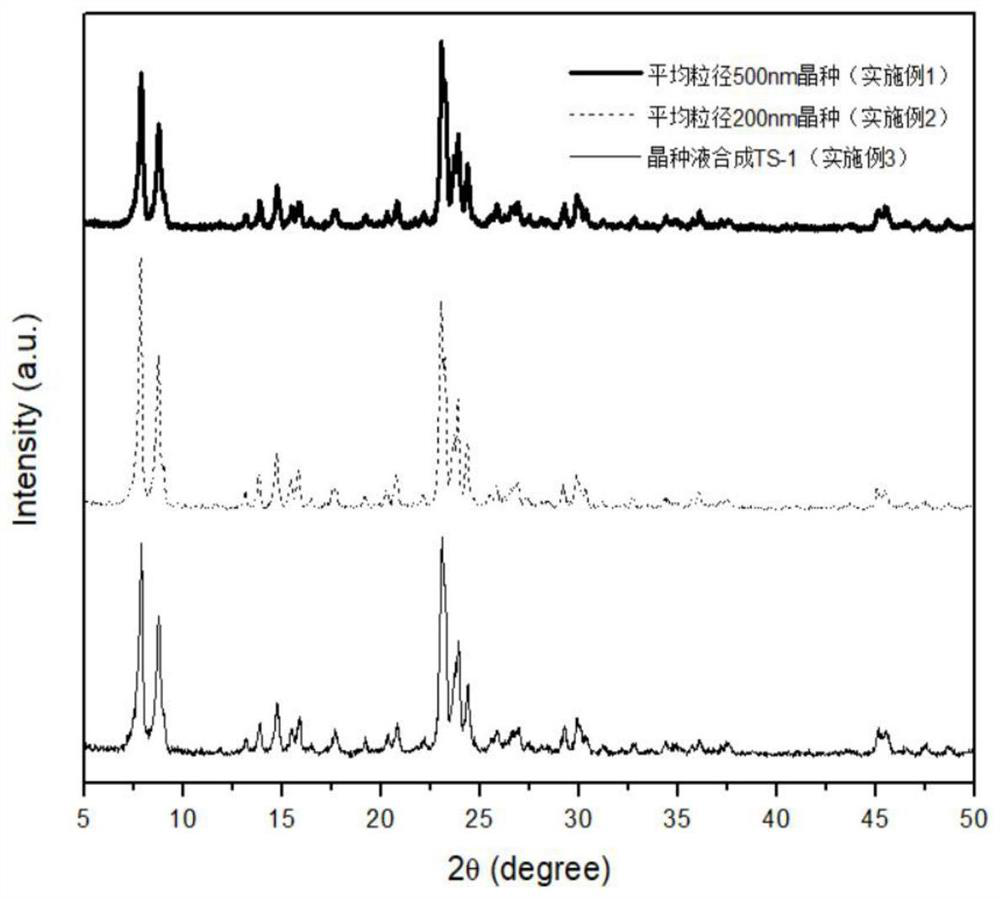

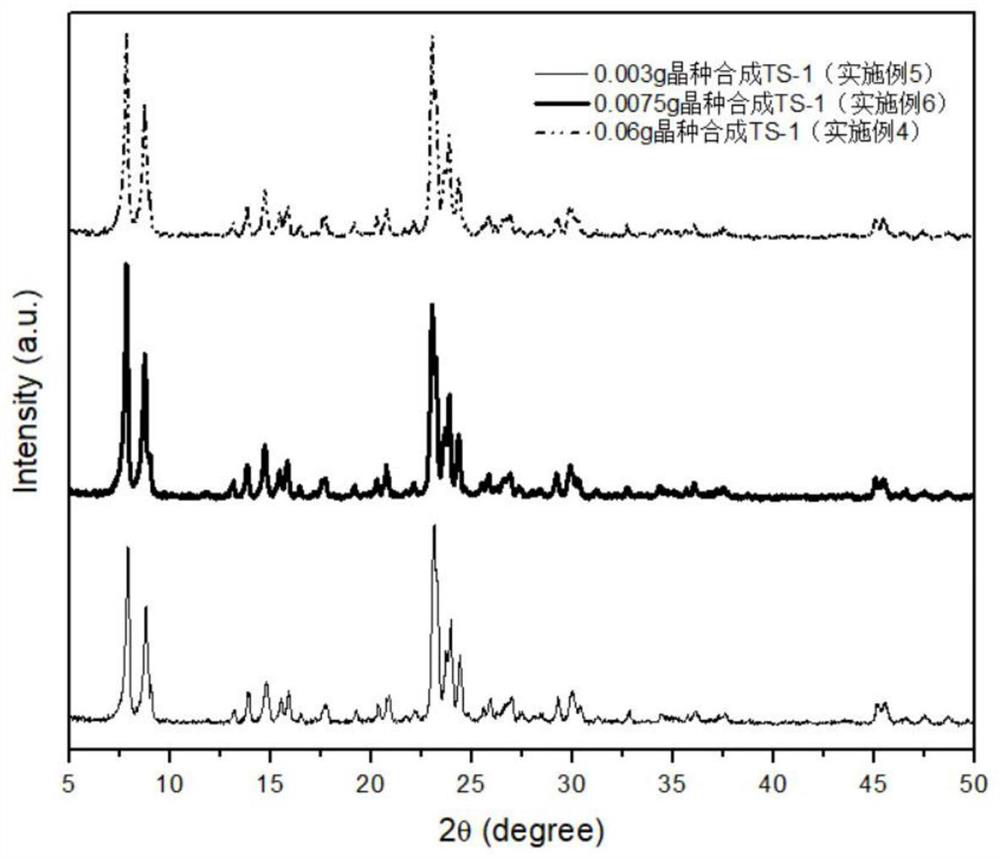

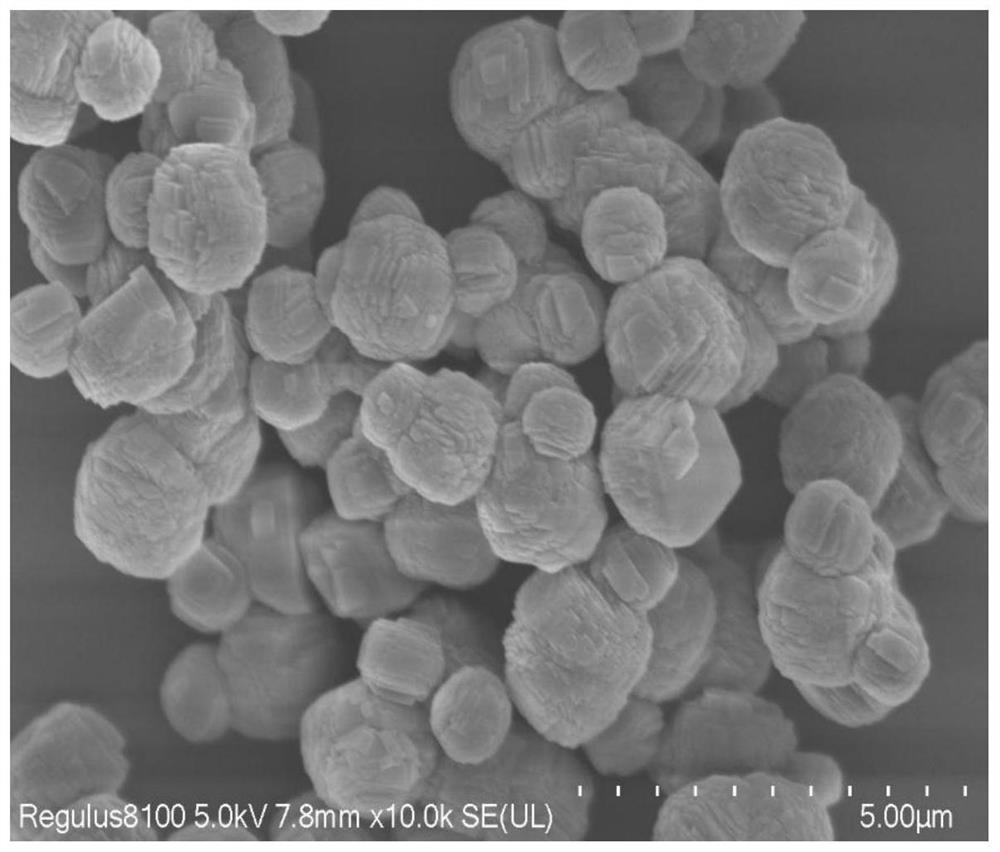

[0036] After XRD analysis, the TS-1 zeolite structure belongs to the MFI structure, such as figure 1 As shown, and through the SEM image, it can be seen that there are more TS-1 zeolites of about 2 μm in the crystal grains, such as image 3 As shown, the pore structure of the synthesized zeolite is microporous, such as Image 6 shown.

Embodiment 2

[0038] A method for synthesizing TS-1 zeolite by a solvent-free method of adjustable size, comprising the following steps:

[0039] Put 0.60g of fumed silica and 0.81g of tetrapropylammonium hydroxide containing 0.61g of water in a mortar and grind to a particle size of 0.6 μm, then add 0.015g of pure silicalite seed crystals with an average particle size of 200nm and sulfuric acid Continue to grind 0.024g of titanium until the particle size is 0.2μm, and then place it in a reactor for crystallization. The reaction temperature is 180°C, and the reaction time is 24h. The obtained product is subjected to suction filtration, baked at 60°C for 12h, and calcined at 550°C for 6h to obtain TS -1 zeolite;

[0040] After XRD analysis, the TS-1 zeolite structure belongs to the MFI structure, such as figure 1 As shown, the particle size distribution of the zeolite is determined to be concentrated around 850nm through the SEM image, as shown in Figure 4 shown by Image 6 The TS-1 zeol...

Embodiment 3

[0042] A method for synthesizing TS-1 zeolite by a solvent-free method of adjustable size, comprising the following steps:

[0043] 0.60g of fumed silica and 1.78g of pure silicalite seed solution (containing 0.21g of tetrapropylammonium hydroxide) and 0.024g of titanium sulfate with an average particle size of 80nm are ground to a particle size of 0.5 μm, and then loaded into the reaction In the still, after crystallization at 180°C for 24 hours, the product was suction filtered, baked at 60°C for 18 hours, and calcined at 550°C for 5 hours to obtain the product. (Because the seed crystal is too small, it is not easy to separate, so the seed crystal liquid is directly used, and the seed crystal liquid is used to adjust the size of the TS-1 zeolite by using the 80nm seed crystal in the solution.)

[0044] Its structure is consistent with the MFI structure through XRD pattern analysis, such as figure 1 shown by Figure 5 It can be seen that the particle size of the synthesize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com