High-temperature combined tabular corundum sagger and manufacturing process thereof

A tabular corundum and production process technology, applied in the field of high-temperature saggars, can solve the problem of saggars entering materials and other problems, and achieve the effects of saving energy, avoiding pollution and resource waste, and having high recyclable value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A manufacturing process for a high-temperature combined plate-shaped corundum sagger, comprising the following steps:

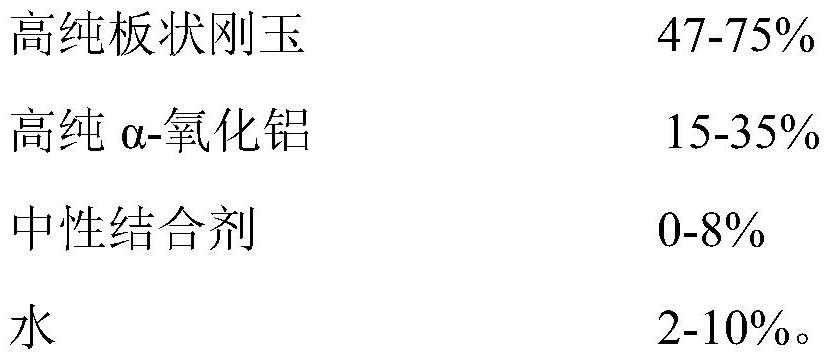

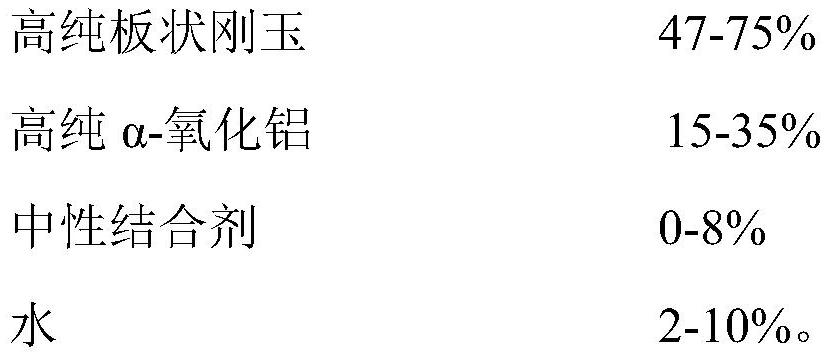

[0038] (1) Mix 65% high-purity tabular alumina, 20% high-purity α-alumina, and 1.0% neutral binder evenly, add water and stir for 2 hours to make a slurry;

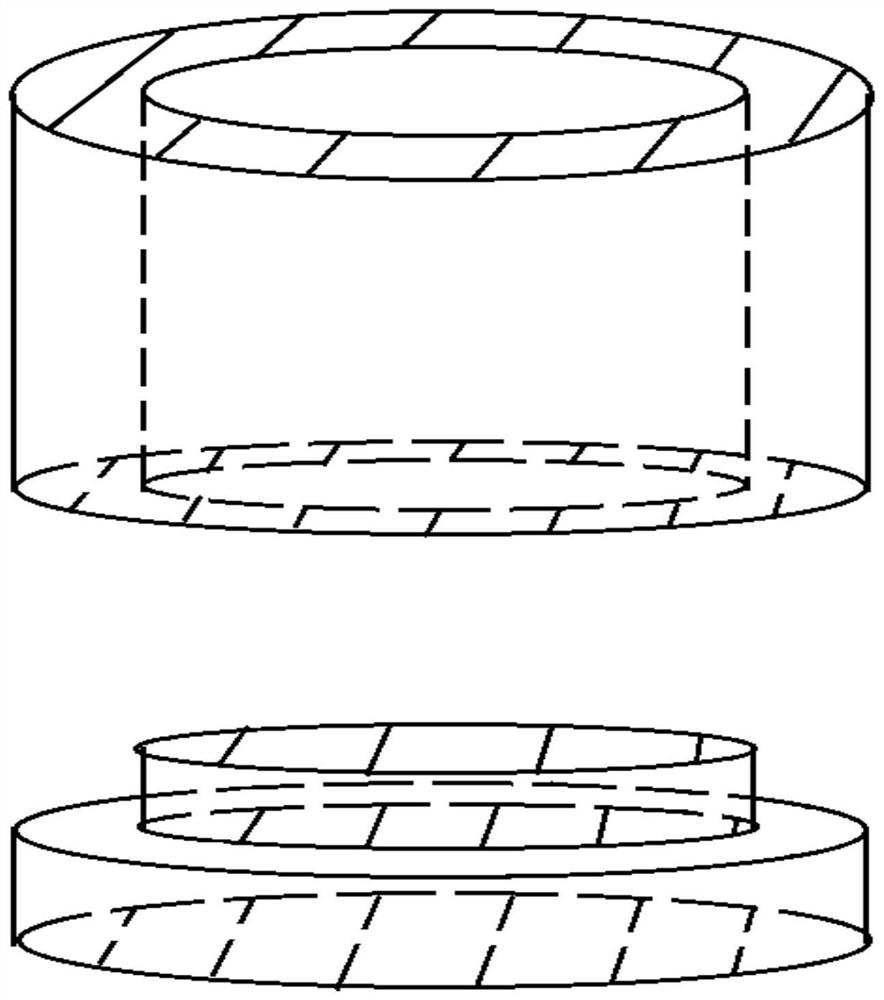

[0039] (2) Add the obtained slurry into a metal mold, and vibrate and press it through an upper-mounted vibration pressing molding machine to obtain a combined plate-shaped corundum sagger, which is composed of two parts. upper base;

[0040] (3) drying the sagger body at 90°C for 8 hours;

[0041] (4) Put the sagger body in a high-temperature kiln for sintering at 1600° C. for 1.5 hours, take it out, cool it, and polish it to obtain a high-temperature combined plate-shaped corundum sagger.

Embodiment 2

[0043] A manufacturing process for a high-temperature combined plate-shaped corundum sagger, comprising the following steps:

[0044] (1) Mix 75% high-purity tabular alumina, 20% high-purity α-alumina, and 2.0% neutral binder evenly, add water and stir for 2 hours to make a slurry;

[0045] (2) Add the obtained slurry into a metal mold, and vibrate and press it through an upper-mounted vibration pressing molding machine to obtain a combined plate-shaped corundum sagger, which is composed of two parts. upper base;

[0046] (3) drying the sagger body at 100°C for 10 hours;

[0047] (4) Put the sagger green body in a high-temperature kiln for sintering at 1700° C. for 2 hours, take it out, cool it, and polish it to obtain a high-temperature combined plate-shaped corundum sagger.

Embodiment 3

[0049] A manufacturing process for a high-temperature combined plate-shaped corundum sagger, comprising the following steps:

[0050] (1) Mix 70% high-purity tabular alumina, 25% high-purity α-alumina, and 3% neutral binder evenly, add water and stir for 2 hours to make a slurry;

[0051] (2) Add the obtained slurry into a metal mold, and vibrate and press it through an upper-mounted vibration pressing molding machine to obtain a combined plate-shaped corundum sagger, which is composed of two parts. upper base;

[0052] (3) drying the sagger body at 95°C for 9 hours;

[0053] (4) Put the sagger green body in a high-temperature kiln for sintering at 1650° C. for 2 hours, take it out, cool it, and polish it to obtain a high-temperature combined plate-shaped corundum sagger.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com