A kind of air-jet vortex spinning multi-component antibacterial yarn and preparation method thereof

An antibacterial yarn and vortex spinning technology, applied in the textile field, can solve the problems of unevenness, affecting the quality of the fabric, details, increase of thick knots and neps, etc., and achieve the effect of high strength and good antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 A kind of preparation method of air-jet vortex spinning multi-component antibacterial yarn

[0031] (1) Raw materials

[0032] The raw materials required for the antibacterial yarn include combed fine-staple cotton, combed long-staple cotton, fine-denier polyester staple fiber, antibacterial polyester staple fiber, and lyocell staple fiber;

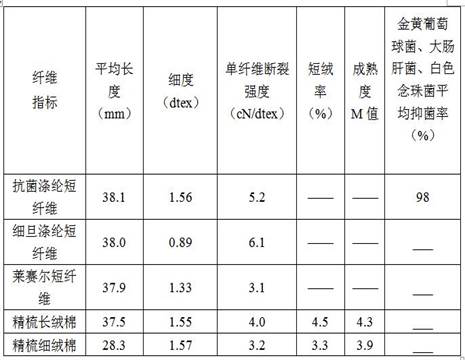

[0033] The technical indicators of the above-mentioned raw materials are shown in Table 1.

[0034] Table 1 List of main indicators of raw materials

[0035]

[0036] (2) Preparation of combed sliver

[0037] The combed fine-staple cotton and combed long-staple cotton are evenly packed in the A002C cotton grabbing machine according to the weight to ensure that the two kinds of cotton are mixed evenly according to the mass ratio of 50%. After passing through the A036B cotton opener-FA022 multi warehouse Mixing machine-A035A Mixing opener-A092A Cotton box feeder-A076C lapping machine-FA201B carding machine-FA334 sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com