Controllable heat dissipation system and controllable heat dissipation method based on semiconductor refrigeration

A technology of heat dissipation system and heat dissipation method, which is applied in the direction of modification by conduction heat transfer, cooling/ventilation/heating modification, modification with gaseous coolant, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

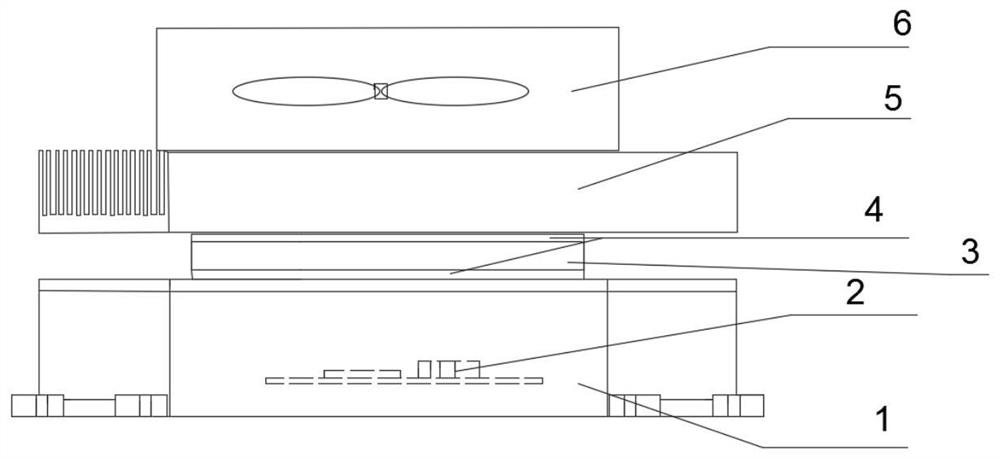

[0031] like figure 1 As shown, the controllable heat dissipation system and controllable heat dissipation method based on semiconductor refrigeration include a circuit board box 1, and also include a control board 2, a heat-conducting silica gel 4, a thermoelectric semiconductor 3, a heat sink 5 and a fan 6, and the circuit board box 1 A control board 2 is installed in the inside, the bottom surface of the thermoelectric semiconductor 3 and the top surface of the circuit board box 2 are pasted by heat-conducting silica gel 4, and the top surface of the thermoelectric semiconductor 3 and the bottom surface of the heat sink 5 are pasted by heat-conducting silica gel 4; A fan 6 is installed on the top surface of the heat sink 5 .

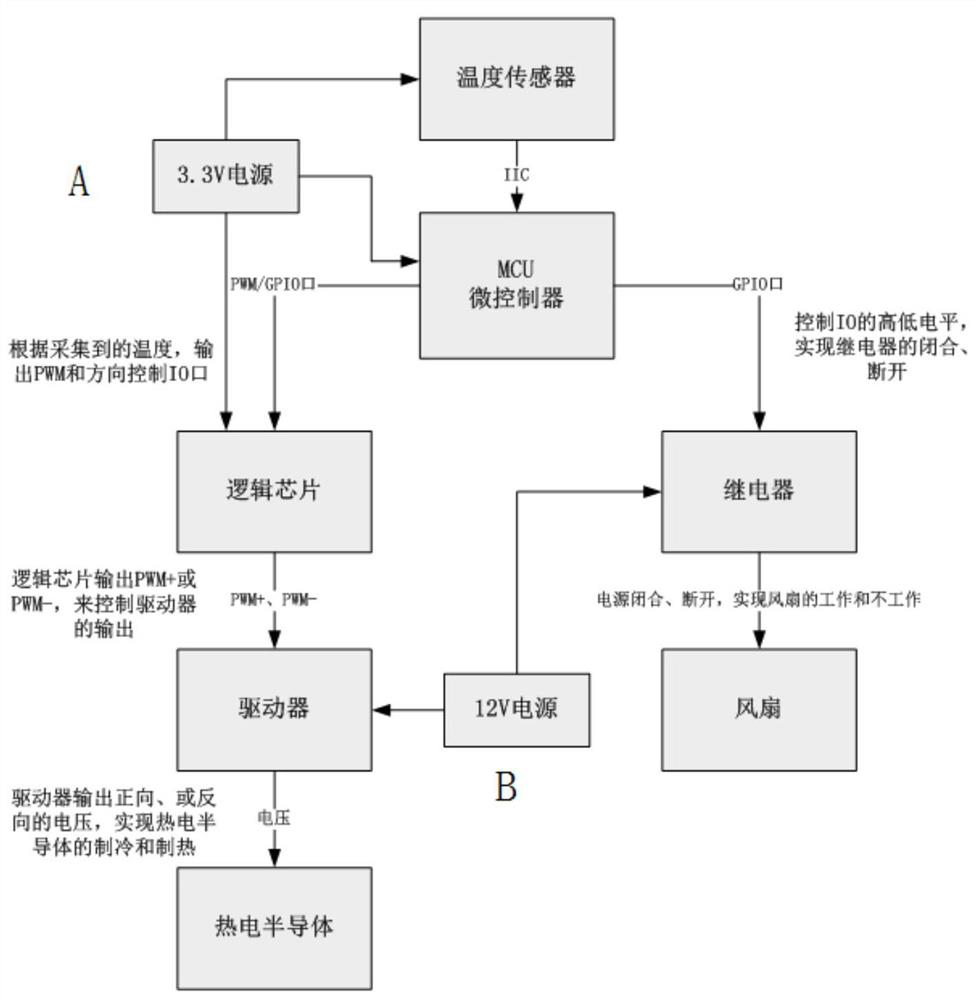

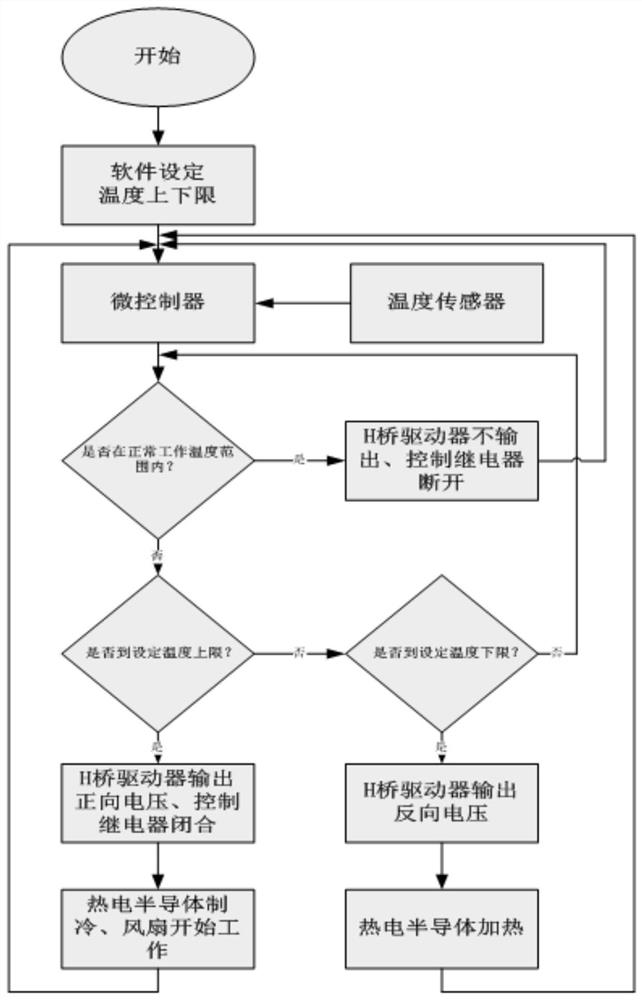

[0032] like figure 2 As shown, the control board 2 includes a logic chip, a driver, a microcontroller, a relay, a temperature sensor, a 3.3V power supply and a 12V power supply; wherein, after a certain temperature is reached in the board box, the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com