Ultrathin flexible vapor chamber and manufacturing method

A vapor chamber, flexible technology, applied in the field of ultra-thin flexible vapor chamber and its production, can solve the problems of unfavorable large-scale application of ultra-thin flexible electronic equipment, poor thermal conductivity, high price, etc., and achieve equilibrium evaporation limit and condensation limit. , The effect of reducing wrinkle height and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

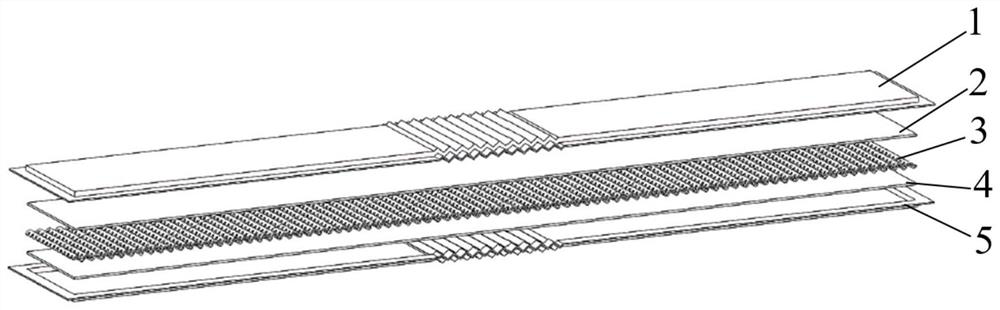

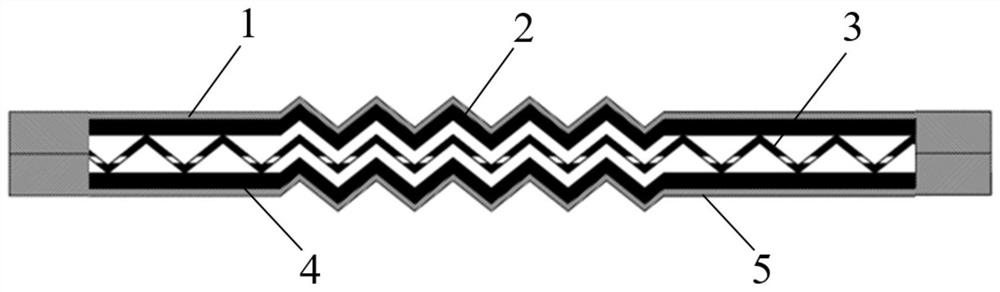

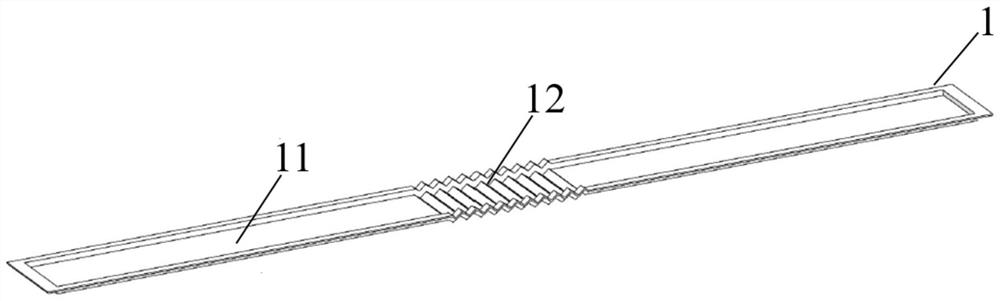

[0035] like Figure 1-Figure 5 As shown, an ultra-thin flexible vapor chamber with an overall thickness of 0.6mm, including an upper shell plate 1, an upper shell plate liquid-absorbing core 2, a flexible support plate 3, a lower shell plate liquid-absorbing core 4 and Lower shell plate 5. The material of the upper shell 1 and the lower shell 5 is red copper, on which are provided a pit structure 11 and a folded structure 12 integrally formed by stamping; the liquid-absorbing core 2 of the upper shell and the liquid-absorbing core 4 of the lower shell are The flexible porous material is sintered together with the upper and lower shell plates through a graphite mold, and is specifically located in the pit.

[0036] The lower surface of the upper shell plate has a pit structure and is provided with a first fold structure.

[0037] The upper surface of the lower shell plate is a pit structure, and a second corrugation structure is provided at a position corresponding to the fir...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 lies in that the first corrugated structure and the second corrugated structure are respectively located in the middle of the upper and lower shell plates, and the shapes of the first corrugated structure and the second corrugated structure are both triangular.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com