Control method and cooperative control method for automatic baking machine

A control method and automatic technology, applied in the cleaning device of the baking chamber, the loading/unloading of the oven, the coin-operated equipment with instrument control, etc. Errors, reducing the speed of replenishment, etc., to simplify the baking food equipment, shorten the space occupied, and facilitate cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

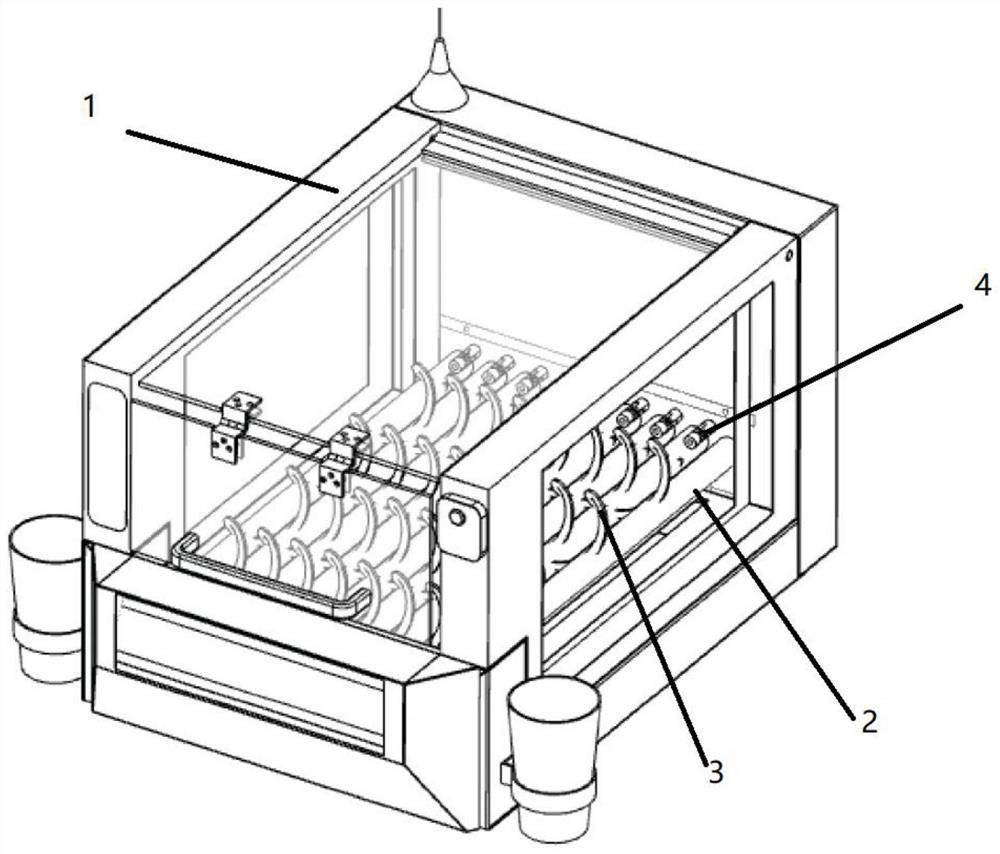

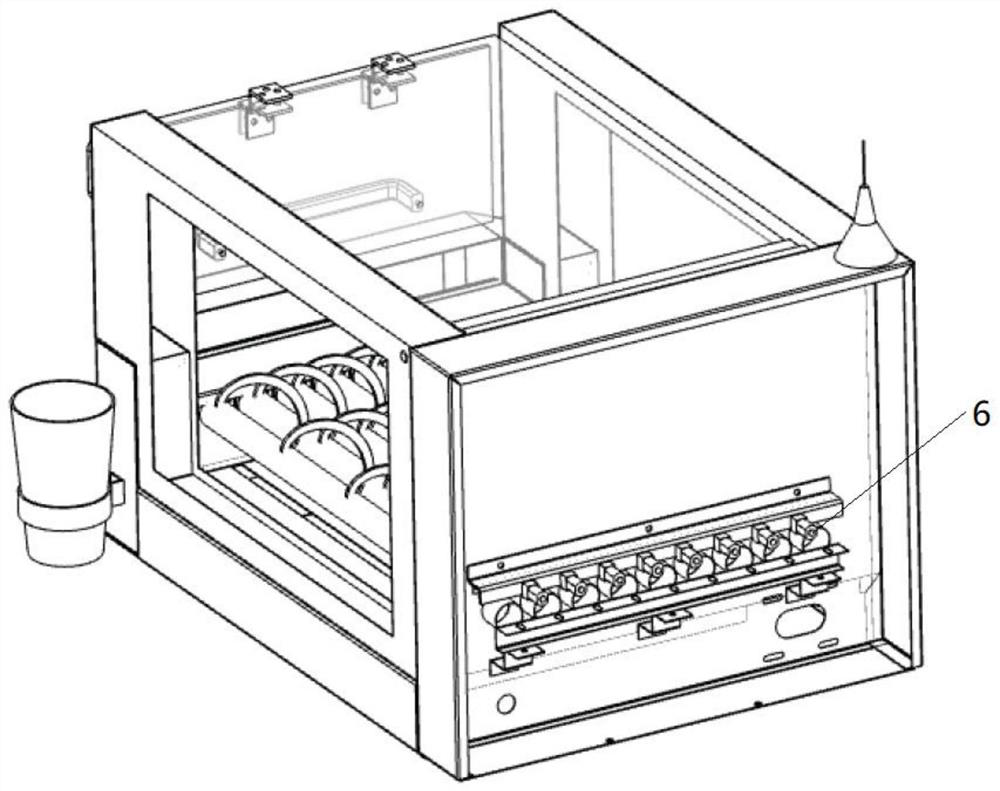

[0028] As a preferred embodiment, the baking machine includes an adapter, and the connector is connected to a motor through a connecting member, which further comprises:

[0029] Control the motor action according to the cleaning mode input by the user, to reset all couplings;

[0030] The coupling is driven to drive the connector and the coil is rotated upward.

[0031] When the automatic baking machine needs to be cleaned, the following process is performed:

[0032] Control the motor action according to the cleaning mode input by the user, to reset all couplings;

[0033] The coupling is driven to drive the connector and the coil is rotated upward.

[0034] This embodiment can lift the coil, facilitate cleaning inside the box, and facilitates the disc.

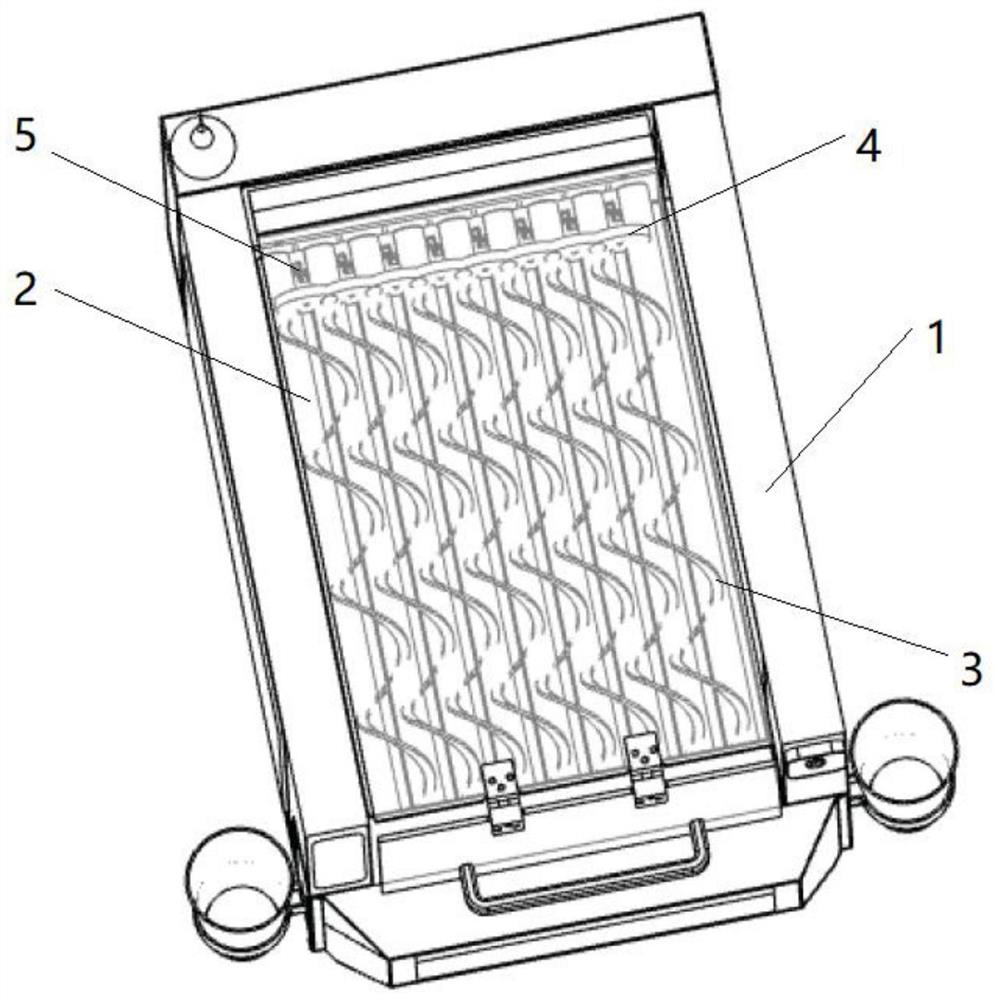

[0035] Such as figure 2 As shown, one end of the coil is fixed to one side surface of the connector, and the joint is disposed on the other side of the connector, rotating upwardly by a coupling coil to make the propellant with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com