Preparation method of fermented bean curd

A technology of fermented bean curd and Lactococcus lactis, which is applied to bacteria and lactobacilli used in dairy products and food preparation, can solve the problems of gas production, juice leakage, browning, and inability to distinguish beneficial bacteria in fermented bean curd, and achieve stable quality and excellent flavor. Healthy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of fermented bean curd in the present embodiment, comprises the following steps:

[0035] S1. Soymilk production: Soak soybeans, refine them, and filter them, then boil them with steam for 20 minutes, heat the cooked milk at ≥98°C for 5 minutes, and sieve to obtain soybean dregs and soybean milk;

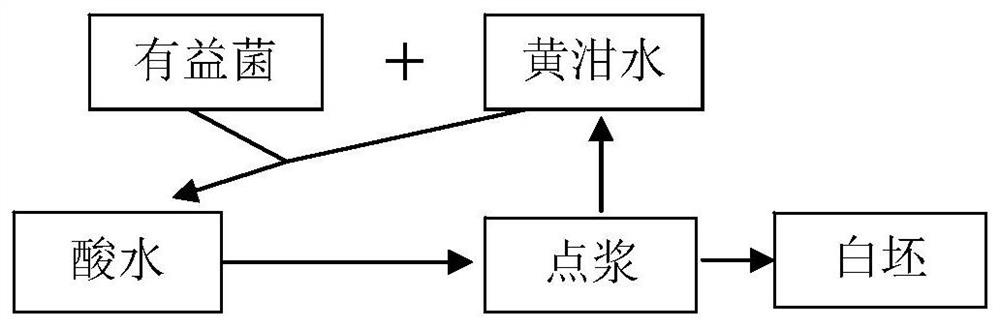

[0036] S2, billet making: the yellow pulp water produced by point pulp is sealed and cooled to below 40°C, inoculated with 5% Lactococcus lactis and fermented naturally for 1 day to form beneficial bacteria acid water with an acidity of 0.7-0.8g / 100ml; The beneficial bacteria acid water is pulped, squeezed, and fermented to obtain a blank;

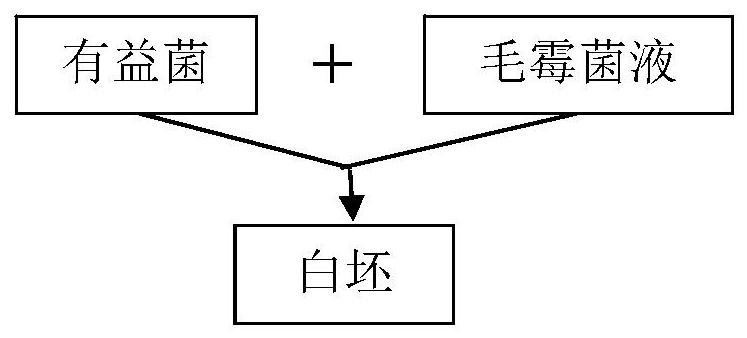

[0037] S3. Seed spraying: use 5% of Lactococcus lactis or Tetradococcus halophilus to mix evenly with 95% of mucormycetes to obtain a mixed bacterial liquid of beneficial bacteria, and inoculate the mixed bacterial liquid of beneficial bacteria on the blank, get blank;

Embodiment 2

[0041] The preparation method of fermented bean curd in the present embodiment, comprises the following steps:

[0042] S1. Soymilk production: Soak soybeans, refine them, and filter them, then boil them with steam for 20 minutes, heat the cooked milk at ≥98°C for 5 minutes, and sieve to obtain soybean dregs and soybean milk;

[0043] S2, billet making: the yellow pulp water produced by point pulp is sealed and cooled to below 40°C, inoculated with 10% Lactococcus lactis and naturally fermented for 1 day to form beneficial bacteria acid water with an acidity of 0.8-0.9g / 100ml; The beneficial bacteria acid water is pulped, squeezed, and fermented to obtain a blank;

[0044] S3, seed spraying: using 10% Lactococcus lactis or Tetradococcus halophilus and 90% mucormycetes to mix uniformly to obtain a mixed bacterial solution of beneficial bacteria, inoculating the mixed bacterial solution of beneficial bacteria on the blank, get blank;

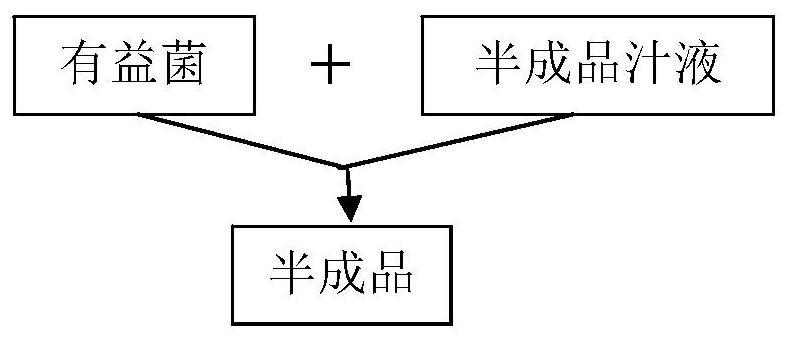

[0045] S4. Pickling: pickling the blank t...

Embodiment 3

[0048] The preparation method of fermented bean curd in the present embodiment, comprises the following steps:

[0049] S1. Soymilk production: Soak soybeans, refine them, and filter them, then boil them with steam for 20 minutes, heat the cooked milk at ≥98°C for 5 minutes, and sieve to obtain soybean dregs and soybean milk;

[0050]S2, billet making: the yellow pulp water produced by point pulp is sealed and cooled to below 40°C, inoculated with 15% Lactococcus lactis and naturally fermented for 1 day to form beneficial bacteria acid water with an acidity of 0.9-1.0g / 100ml; The beneficial bacteria acid water is pulped, squeezed, and fermented to obtain a blank;

[0051] S3. Seed spraying: use 15% of Lactococcus lactis or Tetradococcus halophilus and 85% of mucormycetes to mix evenly to obtain a mixed bacterial liquid of beneficial bacteria, and inoculate the mixed bacterial liquid of beneficial bacteria on the blank, get blank;

[0052] S4. Pickling: pickling the blank to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com