Three-stage countercurrent washing process and device for calcium carbonate based on gypsum conversion

A technology of countercurrent water washing and calcium carbonate, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as increased water treatment costs, large washing water consumption, and complex systems, and achieves a solution for washing Effects of water consumption and equipment occupation, reasonable equipment structure, and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

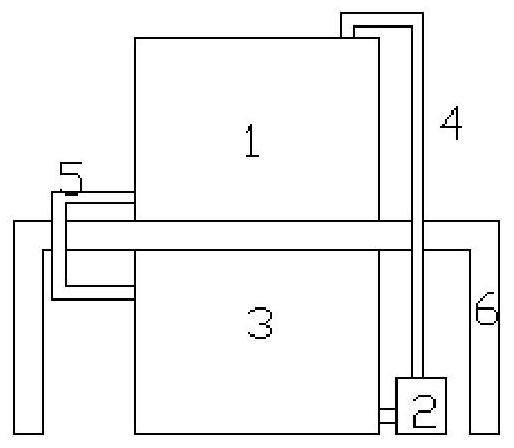

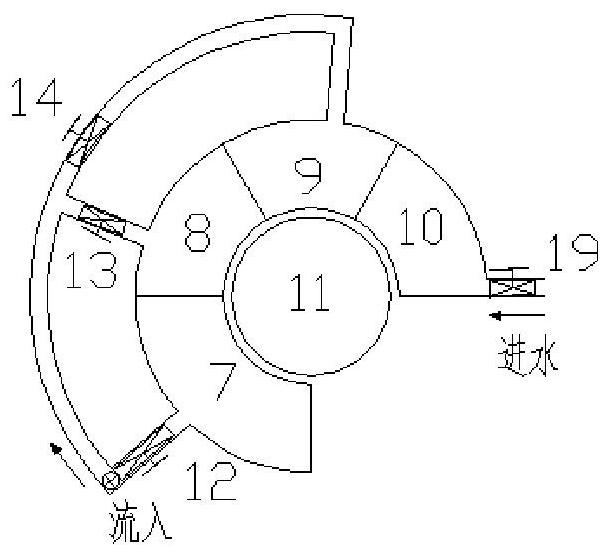

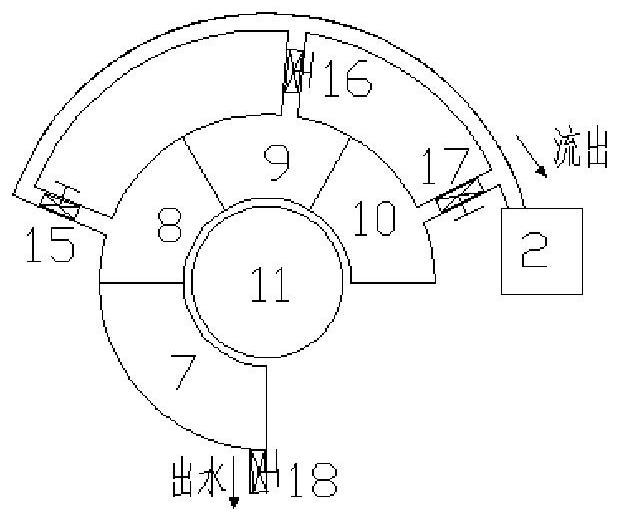

[0025] This embodiment provides a three-stage countercurrent washing device based on calcium carbonate converted from gypsum, including an automatic feeding centrifuge 1, a lotion pump 2, a washing box group 3, an upper water pipe 4, a lower water pipe 5, and a centrifuge stand 6 . The automatic unloading centrifuge 1 is located directly above the washing box group 3, the automatic unloading centrifuge 1 is fixed by the centrifuge stand 6, the outlet of the automatic unloading centrifuge 1 is connected to the inlet of the washing box group 3 through the sewer pipe 5, and the washing box group 3 The outlet is connected to the inlet of the automatic feeding centrifuge 1 through the washing liquid pump 2 and the upper water pipe 4, and the separated liquid enters the washing box group 3 from the automatic feeding centrifuge 1 through the lower water pipe 5 by gravity, and then the washing liquid pump 2 passes through the upper water pipe 4 The liquid is returned to the automatic ...

Embodiment 2

[0032] The present embodiment provides a process for washing with a three-stage countercurrent washing device based on calcium carbonate converted from gypsum, comprising the following steps:

[0033] S1. The calcium carbonate suspension enters the automatic feeding centrifuge 1 for the first solid-liquid separation. After working for 1-10 minutes at a speed of 800-1500r / min, the calcium carbonate solid remains on the separation device, and the easily soluble substances are dissolved in the washing machine. liquid, the liquid inlet valve 12 of the first-level washing liquid tank is opened, and other valves are closed, and the separated liquid (liquid separated from solid-liquid) enters the first-level washing liquid tank 7;

[0034]S2, the outlet valve 15 of the secondary lotion tank is opened, the other valves are closed, the lotion pump 2 is turned on, and the lotion pump 2 is turned off after running for a certain period of time, and a certain amount of liquid is drawn from ...

Embodiment 3

[0043] The present embodiment provides a three-stage countercurrent washing process based on calcium carbonate converted from gypsum, comprising the following steps:

[0044] S1, 30kg of calcium carbonate, 20kg of ammonium sulfate and 50kg of water suspension mixture first enter the centrifuge, work at 1500r / min for 3min, 30kg of calcium carbonate solid is adsorbed on the wall of the centrifuge, at this time the solid contains 2.5kg of water, 1kg ammonium sulfate.

[0045] S2, then inject 10kg of secondary lotion through the water pump, which contains about 0.311kg of ammonium sulfate and 9.689kg of water. After the first washing, 30kg of calcium carbonate solids are adsorbed on the centrifuge wall. Contains 3.160kg of water, 0.340kg of ammonium sulfate.

[0046] S3. At this time, 10kg of third-stage lotion is poured in through the water pump. The lotion contains about 0.081kg of ammonium sulfate and 9.919kg of water. After the second washing, 30kg of calcium carbonate solids...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com