Wood floor chamfering device for house decoration

A wooden floor and edge chamfering technology, which is applied to wood processing equipment, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problems of high labor intensity, time and manpower consumption, and low efficiency, so as to save time and comprehensively Grinding, good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

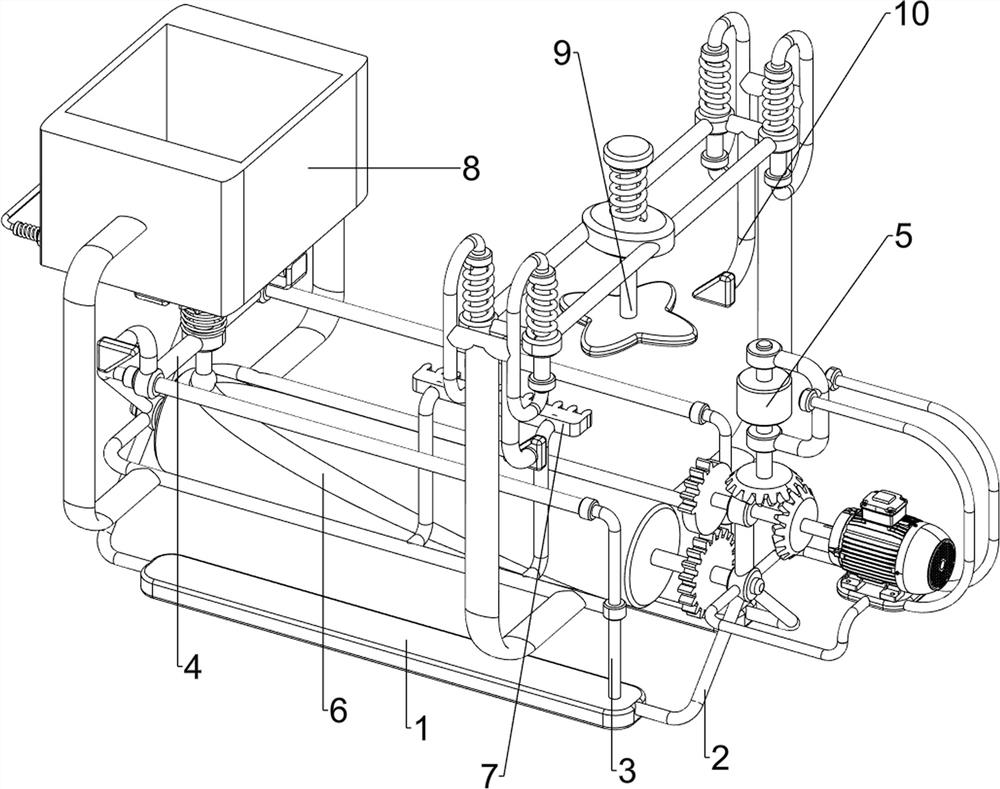

[0068] A wooden floor chamfering device for house decoration, such as figure 1As shown, it includes a base 1, a first support frame 2, a second support frame 3, a fixing mechanism 4 and a polishing mechanism 5, and the left and right sides between the two bases 1 are provided with the first support frame 2, and the two bases 1 The upper right side is equipped with a second support frame 3, the two second support frames 3 are connected with the first support frame 2 on the left side, the first support frame 2 is provided with a fixing mechanism 4, and the right side of the base 1 is provided with a grinding Agency 5.

[0069] When people need to chamfer the wooden floor, people place the wooden floor on the fixing mechanism 4, and then people open the polishing mechanism 5, so that the polishing mechanism 5 rotates, and then people manually move the fixing mechanism 4 to the right, The fixing mechanism 4 drives the wooden floor to move to the right, so that the polishing mecha...

Embodiment 2

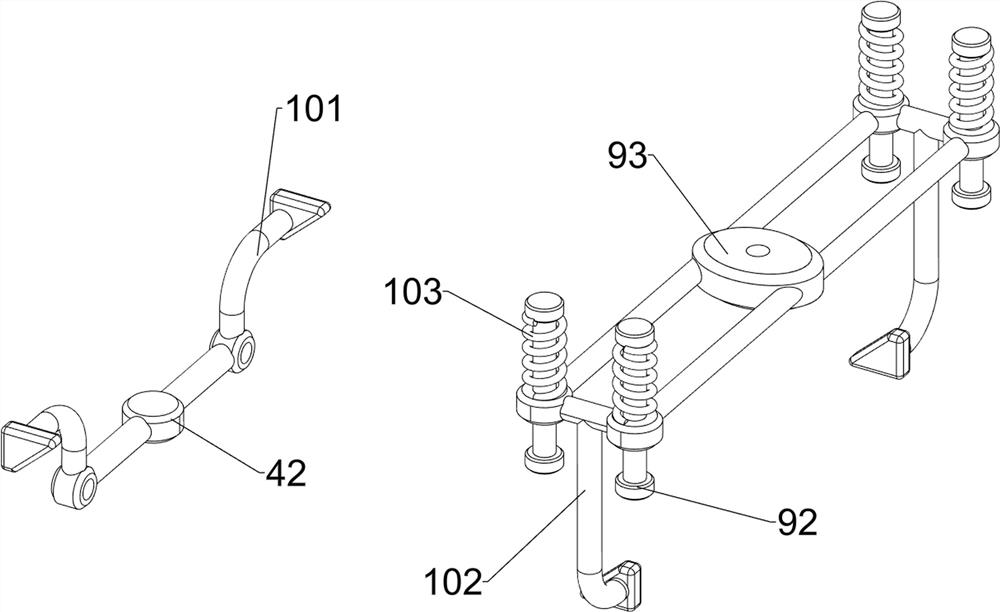

[0071] On the basis of Example 1, such as figure 2 As shown, the fixing mechanism 4 includes a first slide rail 41, a third support frame 42, a first connecting rod 43 and a tray 44, and the front and rear of the first support frame 2 on the left side are provided with the first slide rail 41. A first slide rail 41 is connected with two second support frames 3, a third support frame 42 is slidably provided between the two first slide rails 41, and a first connecting rod 43 is provided in the middle of the third support frame 42 in a rotating manner. , the first connecting rod 43 is provided with a tray 44 .

[0072] When people place the wooden floor on the pallet 44, people will open the grinding mechanism 5, and then people manually move the third support frame 42 to the right, so that the third support frame 42 slides on the first slide rail 41, and then drives The first connecting rod 43 moves to the right, so that the tray 44 moves to the right, so that the wooden floor...

Embodiment 3

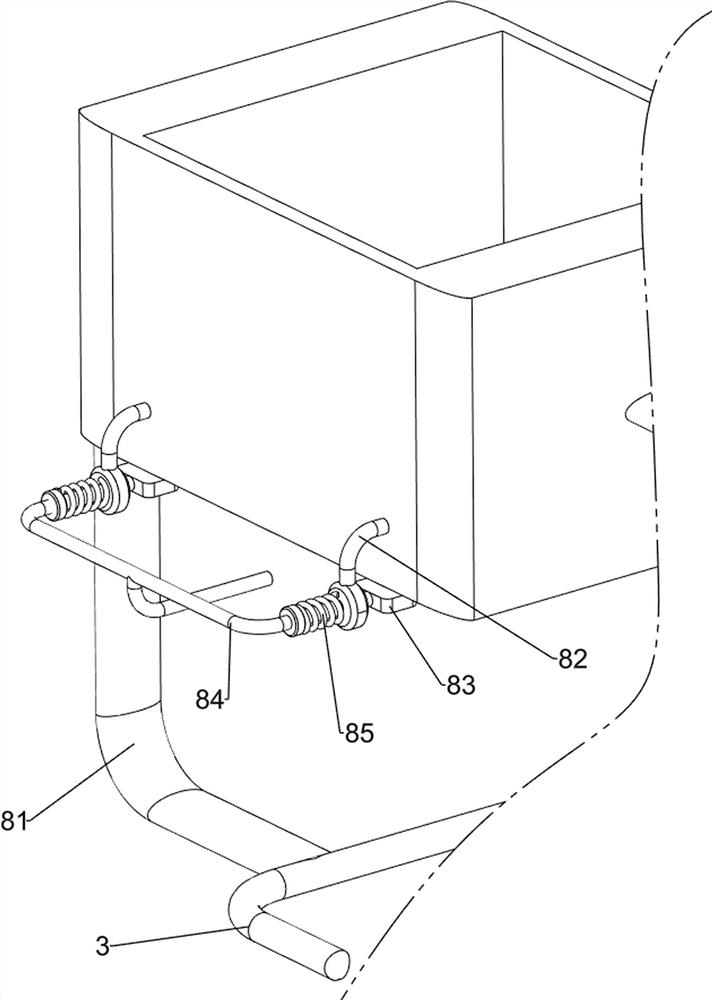

[0074] On the basis of Example 2, such as figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the grinding mechanism 5 includes a fourth support frame 51, a fifth support frame 52, a sixth support frame 53, a motor 54, a first rotating shaft 55, a second rotating shaft 56, a cutting knife 57 and a bevel gear assembly 58, the right side A fourth support frame 51 is provided between the front and rear ends of the first support frame 2, the fifth support frame 52 is provided on the right side of the fourth support frame 51, and the sixth support frame 53 is provided on the first support frame 2 on the right side. A motor 54 is installed on the fourth support frame 51, the output shaft of the motor 54 is connected with a first rotating shaft 55, the first rotating shaft 55 is connected with the sixth support frame 53 in a rotational manner, and the fifth support frame 52 is rotated between the upper and lower sides. A second rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com