Three-stage rectification method of electronic-grade CHF3

An electronic grade, rectification technology, applied in chemical instruments and methods, organic chemistry, preparation of halogenated hydrocarbons, etc., can solve the problems of failure to meet the requirements of semiconductor use, difficult separation of various impurities deep removal technology, low purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

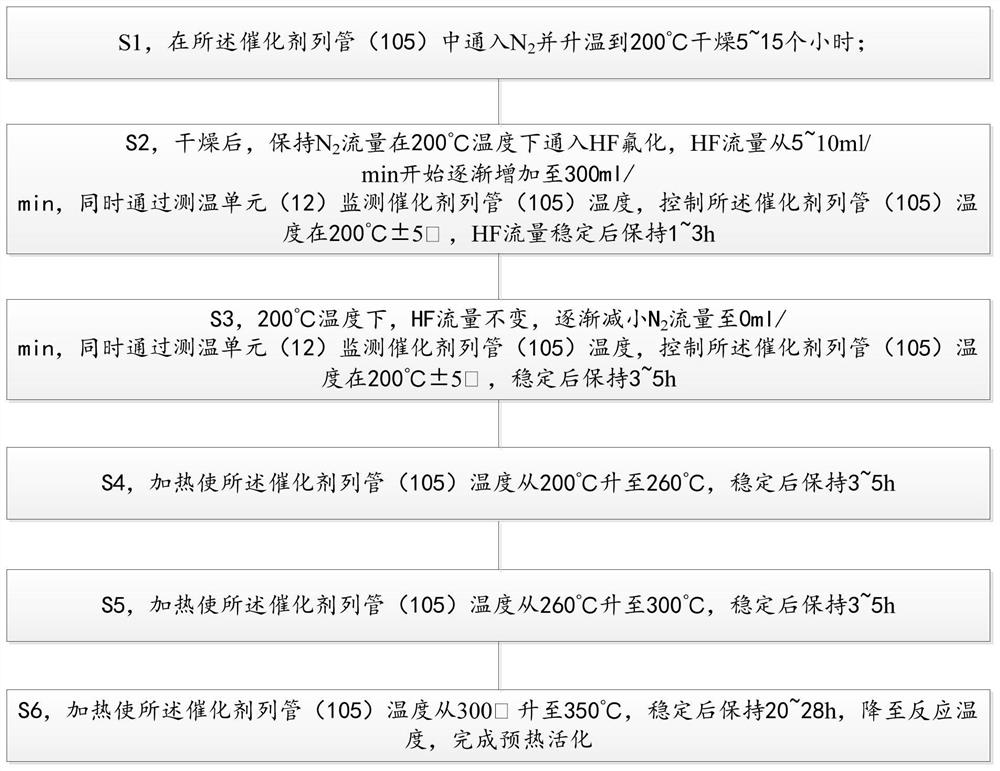

[0041] Please also see Figure 4 , the present invention further provides a kind of electronic grade CHF The novel preparation method comprises: the following steps:

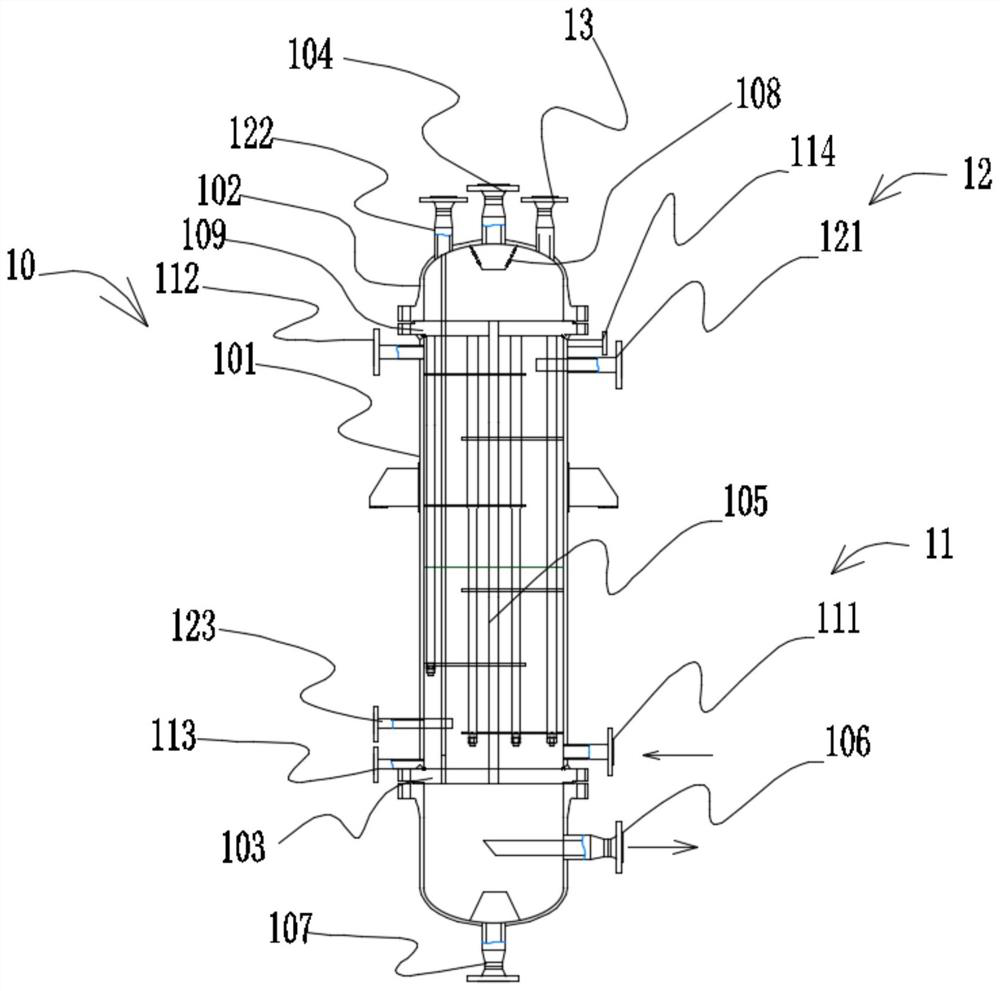

[0042] S7, feed a reaction gas mixed with HF and chlorodifluoromethane from top to bottom into the catalyst tube 105, wherein the ratio of HF to chlorodifluoromethane is 1.05-1.1:1 and HF will be partially dissolved in The water formed is non-reactive, so an excess is required; the catalyst column 105 includes activated catalyst particles;

[0043] S8, controlling the upper temperature of the catalyst tube 105 to 220-230°C, the middle temperature to 245-255°C, the lower temperature to 230-240°C, the reaction pressure to 0.05-0.2Mpa, and the residence time to 40-80s to obtain the catalyst with a purity of 98% or more. Trifluoromethane crude product;

[0044] S9, after the crude trifluoromethane product is washed with water, washed with alkali, dried and rectified, electronic-grade CHF with a purity of 99.9999% ...

Embodiment 1

[0058] The chromium trichloride / activated carbon composite of 8 parts by weight, the aluminum trichloride of 60 parts by weight, the nickel chloride of 3 parts by weight, the magnesium chloride of 5 parts by weight are mixed wherein, chromium trichloride is in said chromium trichloride The content in the activated carbon composite is 20wt%, and it is filled into the catalyst column tube 105 and assembled on the device for activation; N 2 The flow rate is 300ml / min, the catalyst bed temperature is raised to 100°C at a heating rate of 10°C / min, and dried at a constant temperature for 4 hours; the temperature of the catalyst tube 105 is raised to 200°C at a heating rate of 10°C / min, and dried at a constant temperature for 6 hours; 200°C After drying, start fluorination with HF at this temperature; N 2 The flow rate is maintained at 300ml / min, and the HF flow rate is gradually increased from 10ml / min to 300ml / min, which can be adjusted by 20ml / min each time, once every hour. 5°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com