Small mobile laser cladding robot and repair method

A technology of laser cladding and repair methods, which is applied in the coating process and coating of metal materials, can solve the problems of difficult parts to be disassembled and repaired, and achieve the effect of high-precision repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

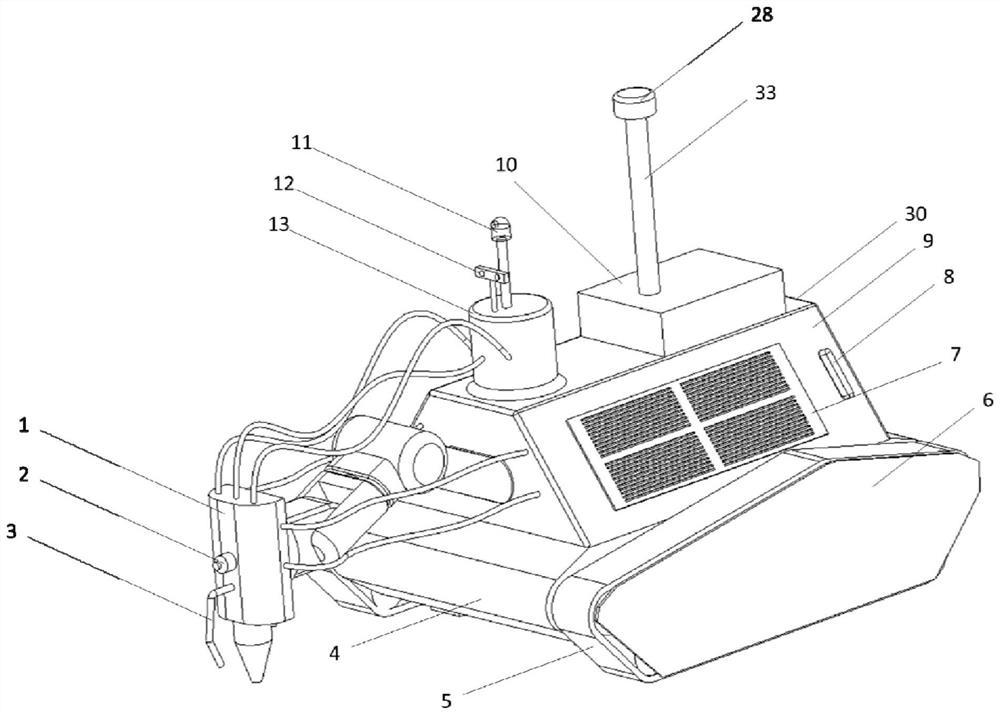

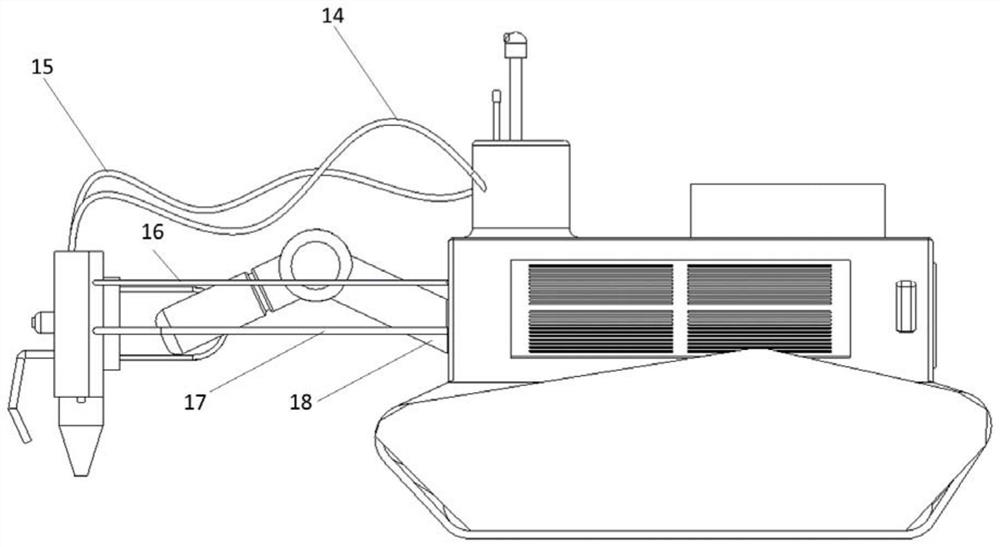

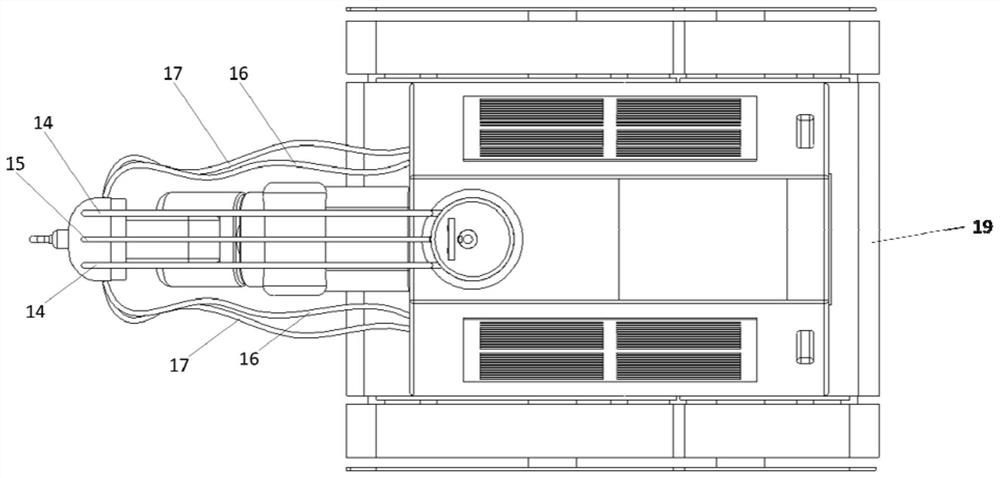

[0039] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 , a small mobile laser cladding robot and repair method, including a laser cladding head, a camera, a multispectral camera, a front track wheel drive device, a track, an antifouling baffle, a side heat dissipation window, a panel push-pull slot, a side panel, Main controller, camera, binocular camera, conveying pipe bracket, powder feeding pipe, laser optical fiber, water cooling pipe, data line pipe, four-degree-of-freedom mechanical arm, rear track wheel drive device, rear heat dissipation window, distance measuring device, mechanical arm Control host, water-cooled host, laser, powder feeder, UPS power supply, cooling fan, lidar, lifting positioning device, fixed cover, front panel, rear panel, lidar bracket.

[0040] Wherein, the moving mode of the small mobile laser cladding robot depends on the moving structure of the crawler belt. The crawler belt is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com