Sprayable moisture absorption type ink for digital printing process of fabric and moisture absorption fabric

A digital printing and ink technology, applied in the direction of ink, coating, application, etc., can solve the problems of unstable fabric quality, low utilization rate of chemicals, color shift, etc., to solve the problem of color fastness decline, waste reduction, and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

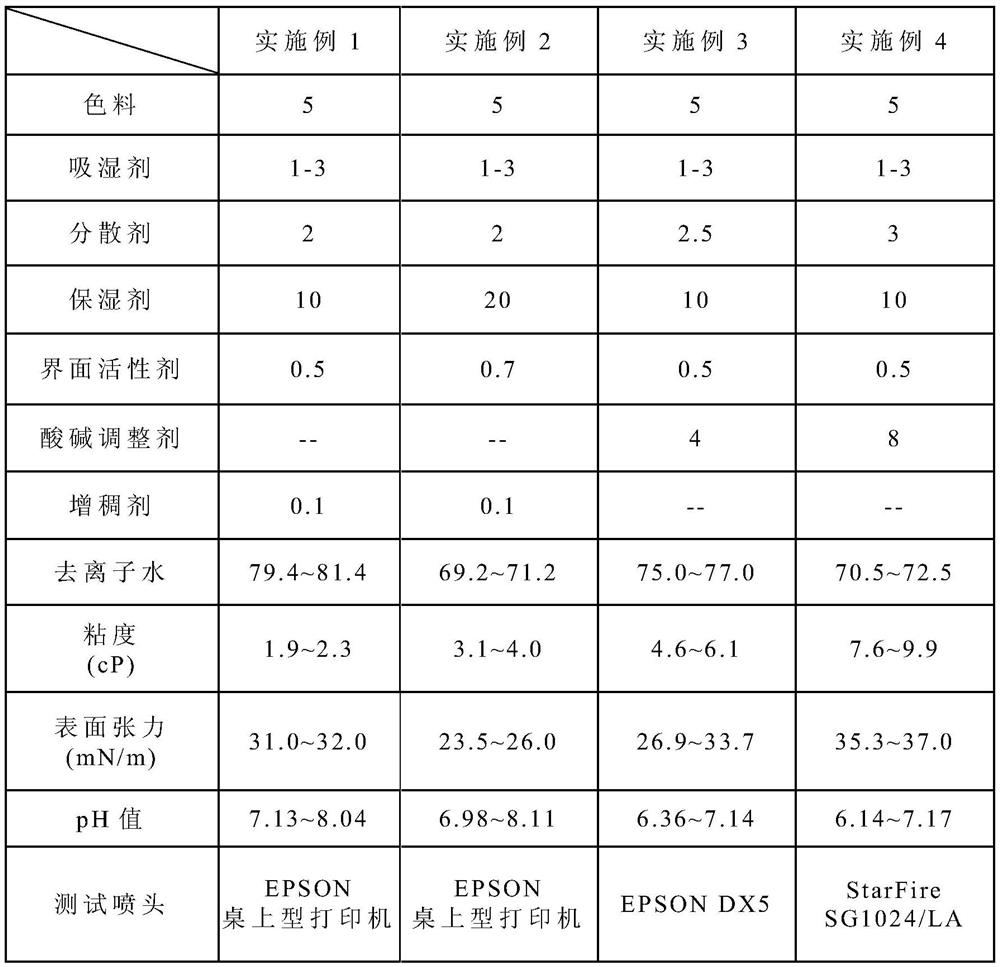

[0044] Experimental example 1: Basic formula evaluation of sprayable hygroscopic ink

[0045] The compositions of the sprayable hygroscopic inks of Examples 1 to 4 are shown in Table 1. In each embodiment, the pigment is a disperse dye, the hygroscopic agent is polyether ester SRT (trade name, provided by Sino-Japanese Synthetic Chemical Company), the dispersant is Solsperse W100 (trade name, provided by Lubrizol company), and the humectant is glycerin and / or Or triethylene glycol (provided by Emperor One Chemical Company), the surfactant is Surfynol 465 (trade name, provided by Air Product Company) and BYK348 (trade name, provided by CABOT Company), and the acid-base regulator is triethanolamine (provided by Emperor One Chemical Company) Provided), the thickener is polyvinylpyrrolidone (provided by Teiichi Chemical Co., Ltd.).

[0046] Table I

[0047]

[0048] *(Numbers without units are parts by weight)

[0049] It can be seen from Table 1 that the viscosity of the sp...

experiment example 2

[0050] Experimental Example 2: Stability Evaluation of Sprayable Hygroscopic Ink

[0051] Disperse dyes of different colors are used as colorants to prepare the sprayable hygroscopic ink of embodiment 5 to embodiment 7, wherein the colorant of embodiment 5 is Cyan disperse dyes, and the colorant of embodiment 6 is Magenta disperse dyes, And the colorant of embodiment 7 is Yellow disperse dye. In addition, the hygroscopic agent of each Example is polyether ester SRT. The sprayable hygroscopic inks of Examples 5 to 7 were subjected to accelerated aging experiments to test the stability of the sprayable hygroscopic inks. The test method is to store the sprayable hygroscopic ink at 50°C for 7 days, and measure the changes of ink viscosity, surface tension, pH value and dispersoid particle size (D90) before and after the experiment, as shown in Table 2.

[0052] Table II

[0053]

[0054] As can be seen from Table 2, after the accelerated aging test of the sprayable hygroscop...

experiment example 3

[0055] Experimental example 3: Evaluation of color difference uniformity after spraying and dyeing fabric with sprayable hygroscopic ink

[0056] The sprayable hygroscopic inks of Examples 5 to 7 were sprayed on non-elastic polyester knitted fabrics and elastic polyester knitted fabrics, and the color difference CMCΔE after spraying was measured with a data color spectrometer, as shown in Table 3.

[0057] Table three

[0058] Color difference CMCΔE Example 5 Example 6 Example 7 Non-elastic polyester knitted fabric 0.25 0.21 0.25 Elastic polyester knitted fabric 0.21 0.27 0.32

[0059] It can be seen from Table 3 that the color difference CMCΔE after the sprayable hygroscopic inks of Examples 5 to 7 are sprayed on fabrics are all less than 0.6. It can be seen that the sprayable hygroscopic ink can be evenly sprayed onto the fabric through the digital printing process, so that the color difference of each block of the fabric is very small (t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com