Underwater-non-dispersion neat paste material dispersion resistance comprehensive tester and application thereof

A comprehensive tester and anti-dispersion technology, which can be used in the analysis of materials, by removing certain components, weighing, instruments, etc., to solve the problem of anti-dispersion performance testing of underwater non-dispersive pure slurry materials that cannot be directly applied, underwater non-dispersion There are no relevant test methods for the pure slurry material, and the anti-dispersion mechanism of concrete is not yet clear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

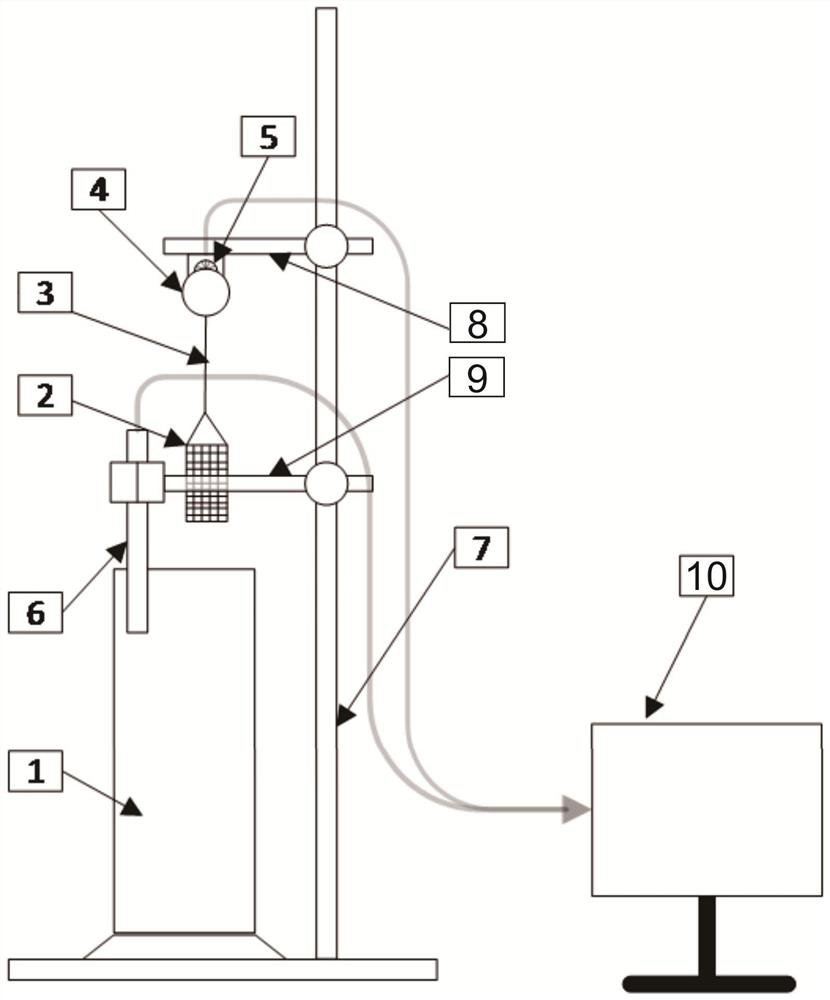

[0028] This embodiment 1 provides a kind of underwater non-dispersible slurry material anti-dispersion comprehensive tester and its application, including the main support 7, the main support 7 is fixedly connected with sub-support one 8 and sub-support two 9, sub-support one 8 is provided with a quality testing device 5, which is specifically a digital electronic scale for real-time recording and transmission of pulp quality data. The accuracy of the digital electronic scale is 0.001g, which ensures the testing accuracy; Connect with the automatic lifting device 4, the automatic lifting device 4 is a lifting motor, the two ends of the PLC controller (specifically Omron CP1H-X40DT-D type PLC controller) are electrically connected with the computer processing terminal 10 and the lifting motor, and the automatic lifting device The lifting motor in No. 4 is also connected to the pulp cleaning container 2 through the connecting rope 3. The pulp cleaning container 2 is a cylindrical...

Embodiment 2

[0039] This embodiment 2 provides a comprehensive tester for anti-dispersion performance of underwater non-dispersible pulp cleaning materials and its application. The difference from embodiment 1 is that the water holding container 1 is specifically a water tank, and the pulp cleaning container 2 is specifically a mesh screen. Cylindrical container with 60 mesh.

experiment example 1

[0041] In order to better illustrate the scientificity and accuracy and reliability of the comprehensive tester for the anti-dispersion performance of the underwater non-dispersible slurry material provided by the present invention and the accuracy and reliability of the test data, this experimental example 1 provides the exploration of the test method related to the tester experiment.

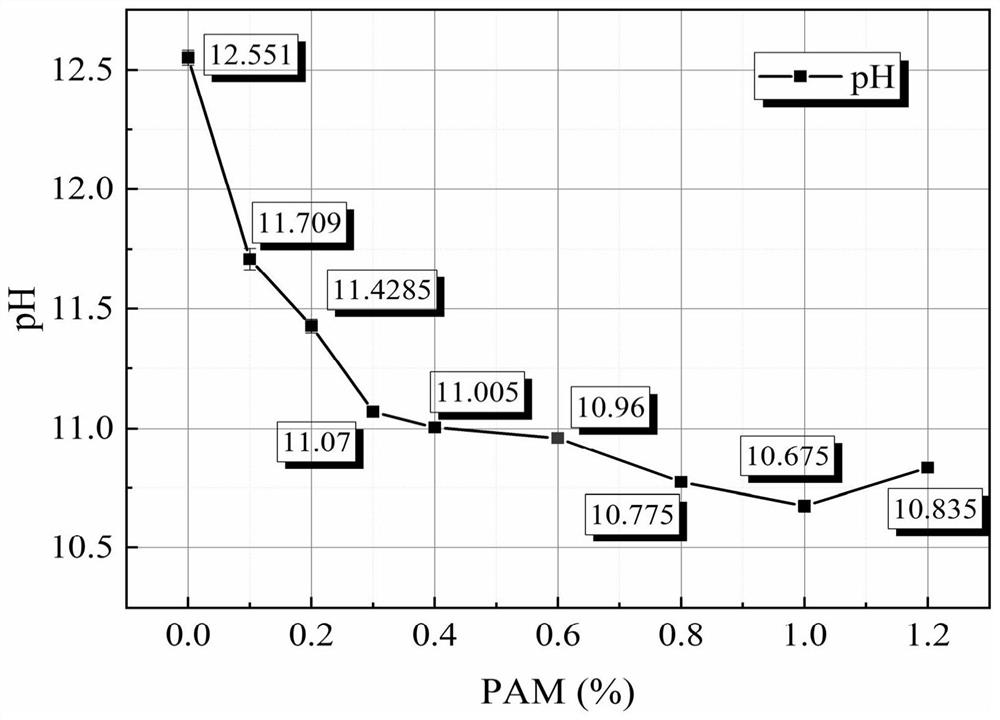

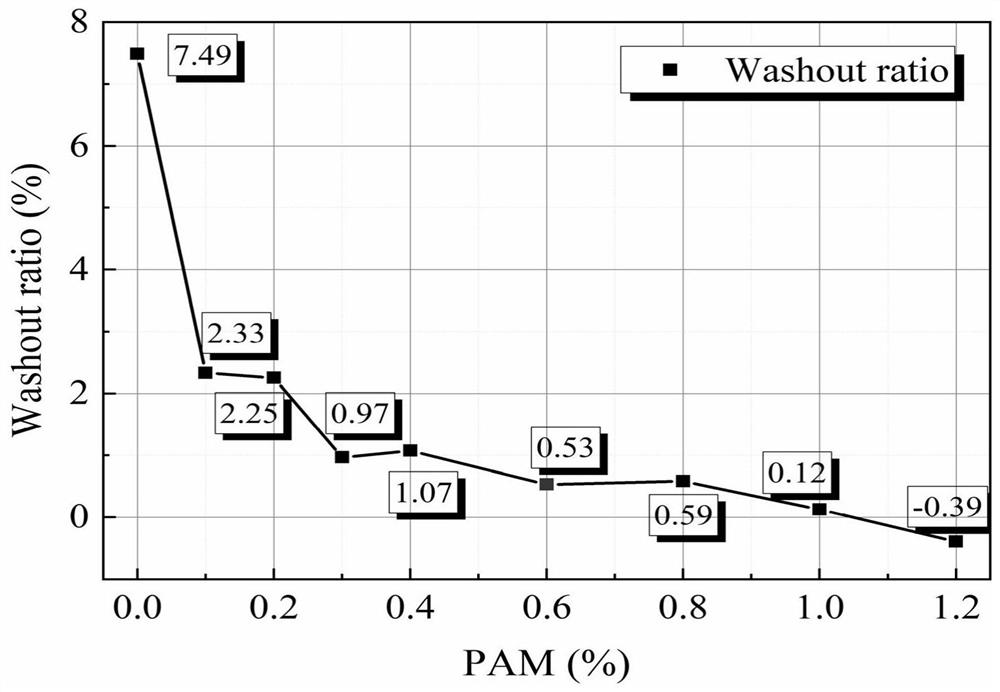

[0042] First, four reasonable and feasible test methods are selected for comparative analysis. The four test methods are weighing method, water shaking method, suspended matter content method and pH method, among which water shaking method belongs to the test method in the field of medical application, suspended matter The content method also belongs to the method described in DL / T 5117-2000. The anti-dispersion performance was tested under different dosages of dispersants in the underwater part. The specific process is: Weighing method: put about 8g of clean slurry material in a cylindrical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com