Partial least square method-based heat-resistant steel degradation state evaluation method

A technology of partial least squares and degradation state, which is applied in the field of performance testing of heat-resistant steel materials, can solve the problems of long testing period, high testing cost, and unsuitable headers, etc., and achieves reduced testing costs, fast evaluation methods, and high accuracy high effect

Pending Publication Date: 2021-06-04

国能锅炉压力容器检验有限公司 +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003]

At present, methods such as long-term high-temperature creep test or short-term high-temperature tensile test are used to evaluate the performance degradation of metal workpieces, which are to test the workpiece under conditions similar to service conditions or accelerate them under conditions that are more severe than service conditions. Test, the test results are highly reliable, but the test cost is high, the detection period is too long, and the workpiece recovery after destructive sampling is difficult, and it is not suitable for headers, valve bodies and other components except for pipelines

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

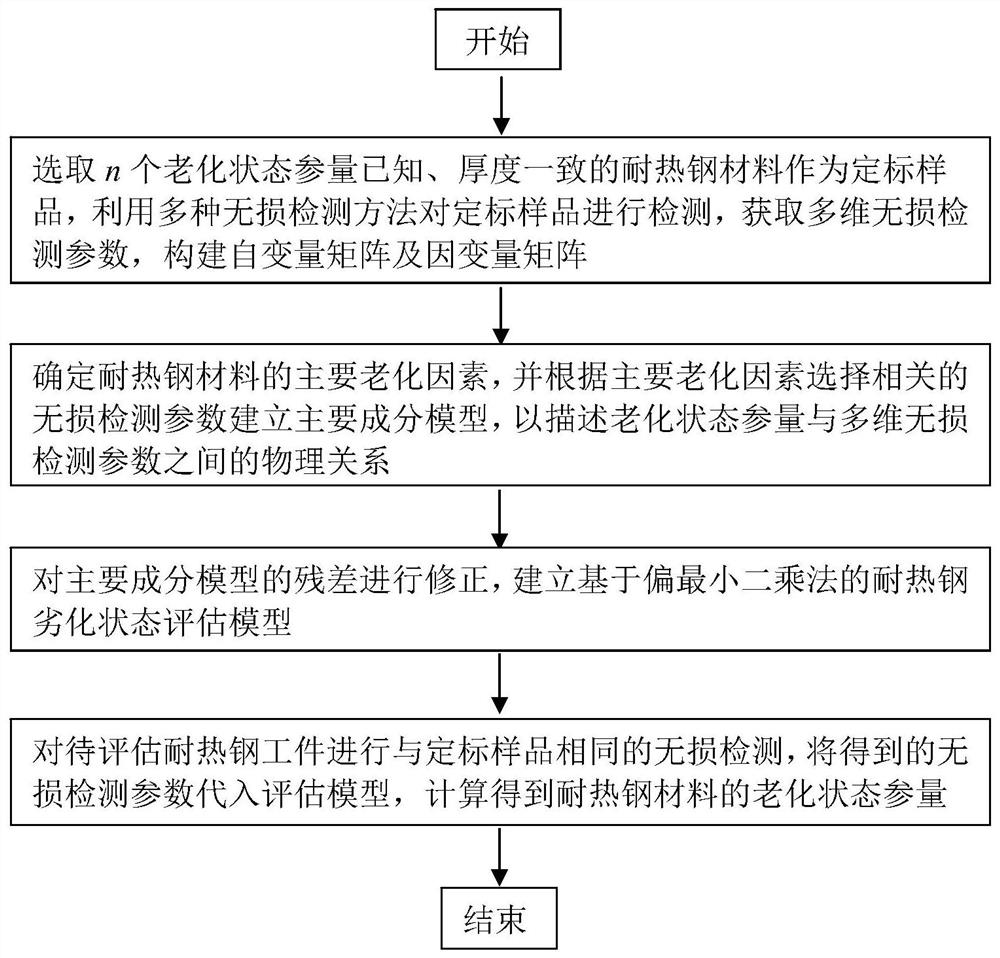

[0060] refer to figure 1 , a method for evaluating the deterioration state of heat-resistant steel based on the partial least squares method, which is used for the evaluation of the deterioration state of ferritic heat-resistant steel and austenitic heat-resistant steel, including the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

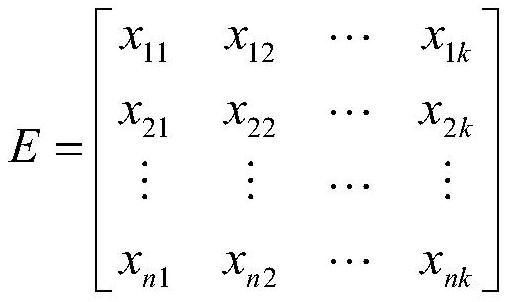

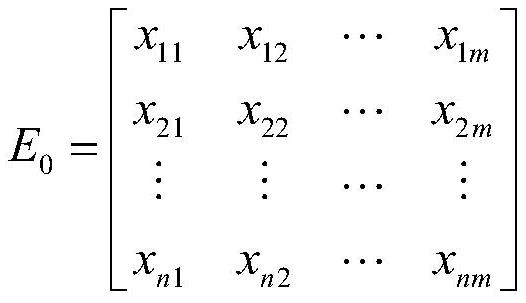

The invention discloses a partial least square method-based heat-resistant steel degradation state evaluation method, which comprises the following steps of: (1) selecting n heat-resistant steel materials with known aging state parameters and consistent thickness as calibration samples, and detecting the calibration samples by utilizing multiple nondestructive testing methods to obtain multi-dimensional nondestructive testing parameters; (2) determining main aging factors of the heat-resistant steel material, and selecting related nondestructive testing parameters according to the main aging factors to establish a main component model so as to describe a physical relationship between aging state parameters and multi-dimensional nondestructive testing parameters; (3) correcting the residual error of the main component model, and establishing a heat-resistant steel degradation state evaluation model based on a partial least square method; and (4) carrying out nondestructive testing which is the same as that of the calibration sample on the heat-resistant steel workpiece to be evaluated, substituting all obtained nondestructive testing data into the evaluation model in the step (3), and calculating and obtaining aging state parameters of the heat-resistant steel workpiece. The method can quickly evaluate the deterioration state of the heat-resistant steel.

Description

technical field [0001] The invention relates to the technical field of performance detection of heat-resistant steel materials, in particular to a method for evaluating the deterioration state of heat-resistant steel based on a partial least square method. Background technique [0002] High-temperature and high-pressure pipes, pipe fittings, valves and other workpieces in power plants and chemical plants are usually made of metal materials that can withstand high temperature and high pressure conditions. With the prolongation of service time, metal materials gradually age. The main performance degradation mechanisms include high temperature creep, Thermal fatigue and creep-fatigue interactions. At present, destructive methods (such as pipe cutting, overall sectioning, etc.) are usually used to sample metal workpieces, and they are tested by means of long-term high-temperature creep tests (thousands to tens of thousands of hours) or short-term high-temperature tensile tests. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06Q10/06G06F30/20G06F17/18G06K9/62G01N33/204

CPCG06Q10/06393G06F30/20G06F17/18G01N33/204G06F18/2135Y02P90/30

Inventor 袁廷璧周龙崔崇常青肖德铭

Owner 国能锅炉压力容器检验有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com