A hydrogen supply system and control method for an air-cooled fuel cell

A fuel cell and supply system technology, which is applied to fuel cells, power system fuel cells, electrical components, etc., can solve problems such as unreasonable exhaust methods, and achieve the effects of simple and efficient implementation, improved work performance, and efficient emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

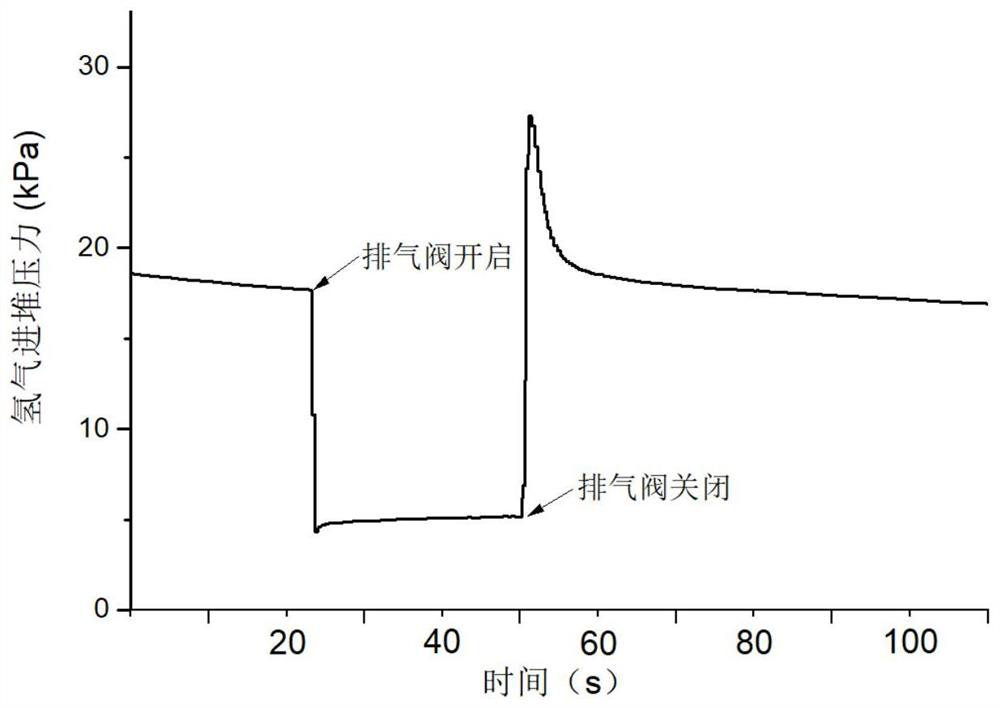

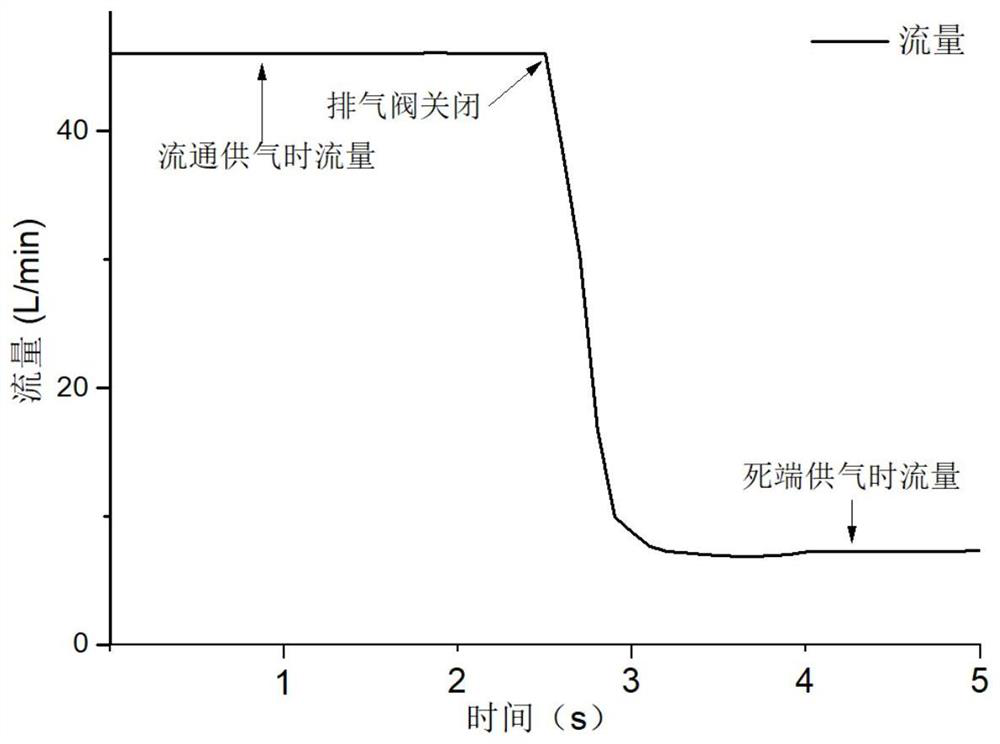

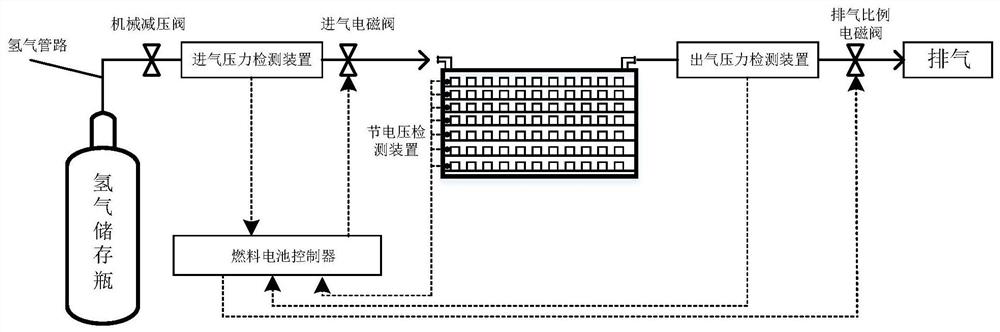

[0037] This embodiment proposes a hydrogen supply system for an air-cooled fuel cell, such as image 3 As shown, it includes a hydrogen storage bottle, a hydrogen pipeline, a mechanical pressure reducing valve, an intake solenoid valve, an exhaust proportional solenoid valve, a fuel cell controller, an intake pressure detection device, an outlet pressure detection device and a voltage saving detection device; The hydrogen storage bottle is connected to the intake end of the air-cooled fuel cell stack through a hydrogen pipeline provided with a mechanical decompression valve, an intake pressure detection device, and an intake solenoid valve in sequence, and the exhaust end of the air-cooled fuel cell stack is passed through the outlet pressure. The detection device and the exhaust proportional solenoid valve are exhausted. The node voltage detection device is arranged on each battery unit in the air-cooled fuel cell stack. The fuel cell controller receives the intake air pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com