Bridgeless multi-level rectifier with common direct current bus and control strategy

A common DC bus and multi-level rectification technology, which is applied in the direction of converting AC power input to DC power output, electrical components, and output power conversion devices, can solve the problem of increasing complexity of system topology and control methods, which cannot Using high-voltage direct current transmission, unable to directly connect in series and other problems, to achieve the effects of high overall work efficiency, cost reduction, control complexity, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiment and working principle of the present invention are further described below in conjunction with accompanying drawing:

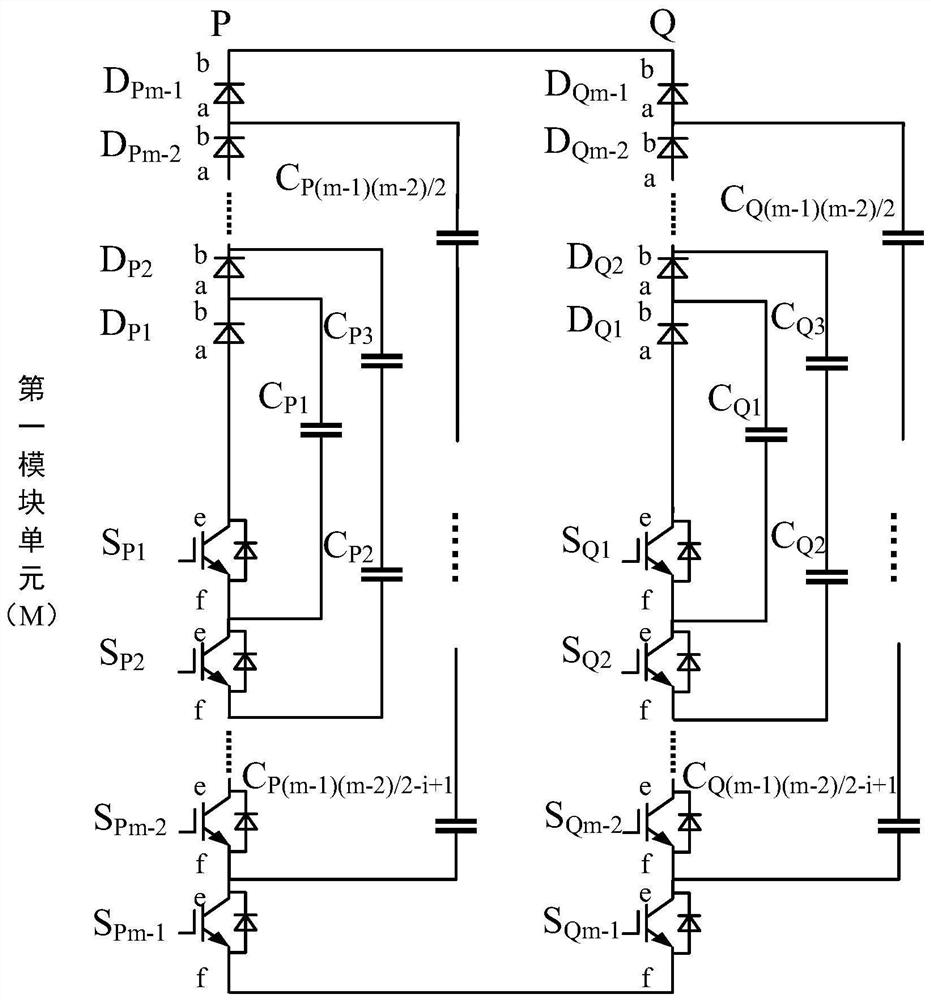

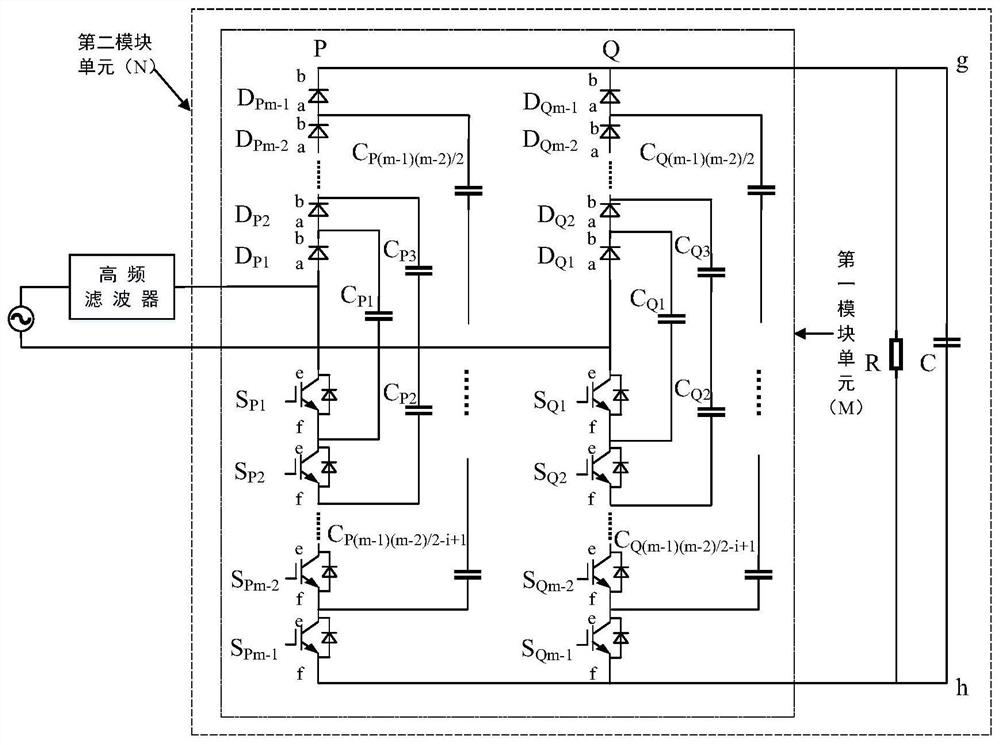

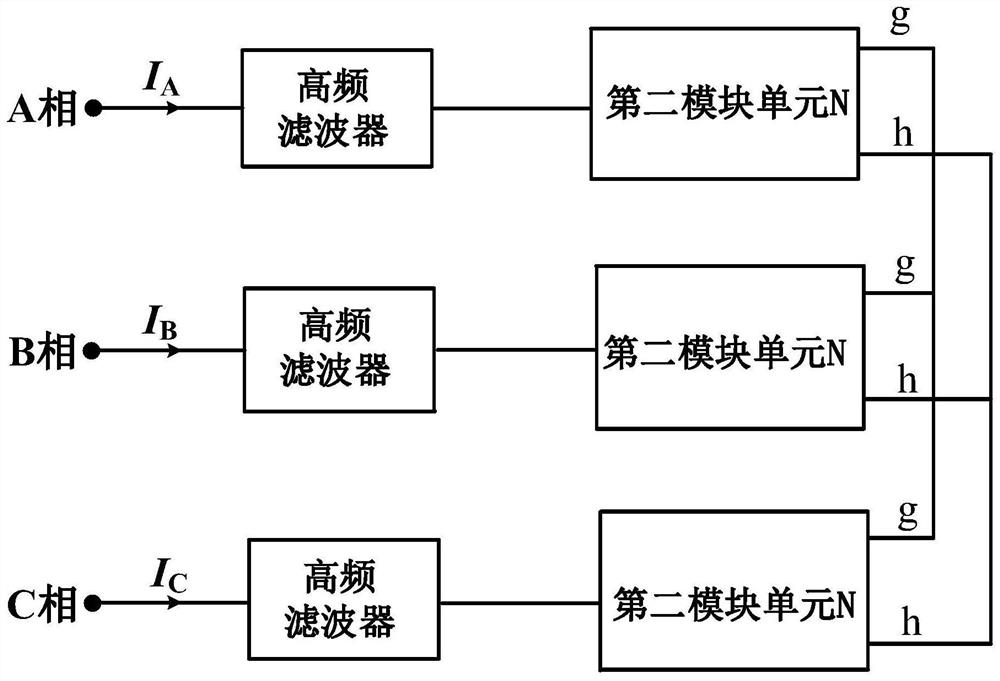

[0042] refer to figure 1 and figure 2 , a bridgeless multilevel rectifier with a common DC bus, including a main power circuit, the main power circuit includes a high frequency filter, a first modular unit (M) of m level (m=2 n -1, where m and n are both positive integers), an output DC capacitor C and a load resistor R, the first module unit (M) includes two first bridge arms P and second bridge arms Q with identical structures, The first bridge arm P includes m-1 switching devices S P1 , S P2 ······S Pm-2 , S Pm-1 , m-1 fast recovery diodes D P1 、D P2 ······D Pm-2 、D Pm-1 , i flying capacitor branch (wherein i=1, 2······m-2), the i-th flying capacitor branch DC capacitor number of the first bridge arm P is i, the first bridge Fast recovery diode D of arm P P1 The second terminal (b) and the fast recovery diode D of the first bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com