Environmental protection water treatment aquatic grass automatic cutting conveyor

An environmental protection and automatic cutting technology, applied in the direction of cutters, harvesters, agricultural machinery and implements, etc., can solve problems such as time-consuming and labor-intensive, blockage of aquatic plants, and hazards to normal operation of water conservancy projects, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

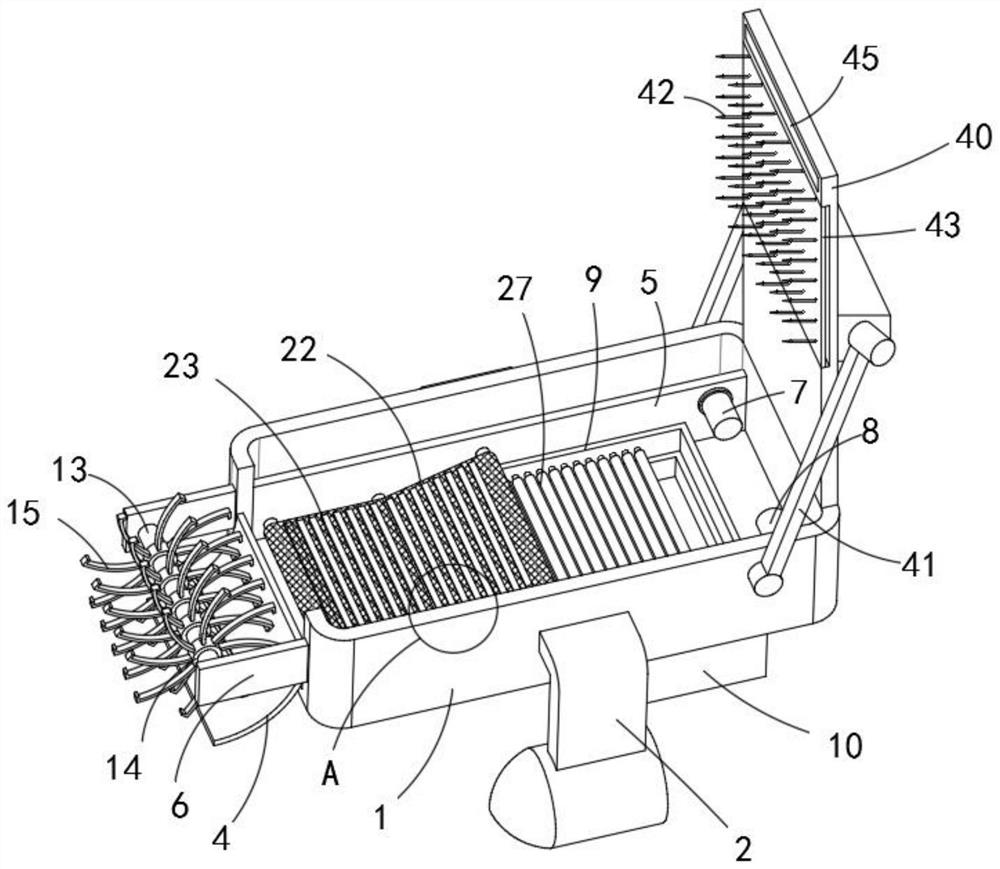

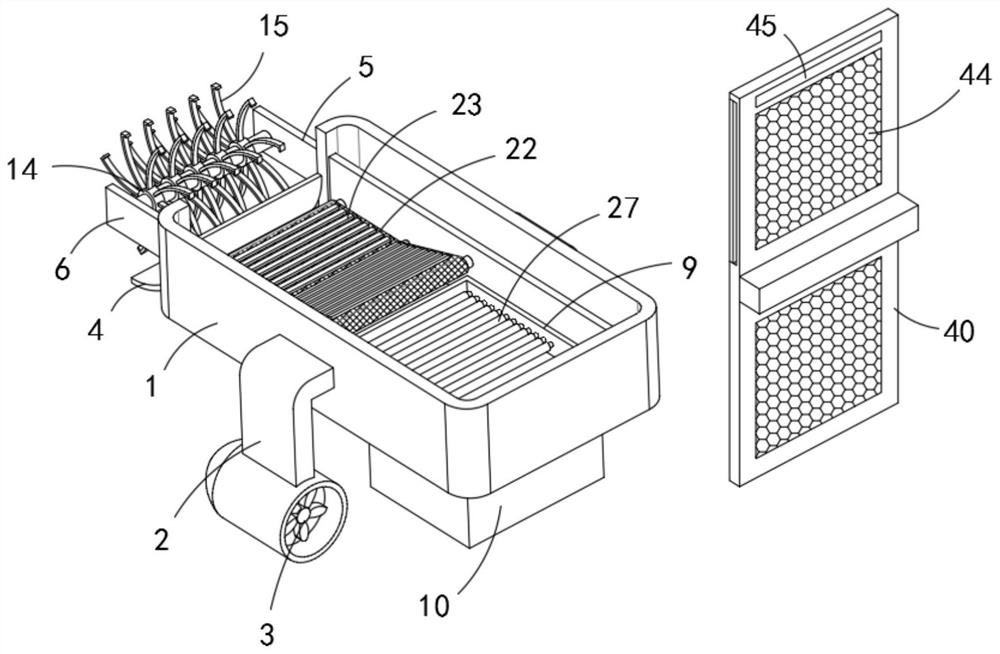

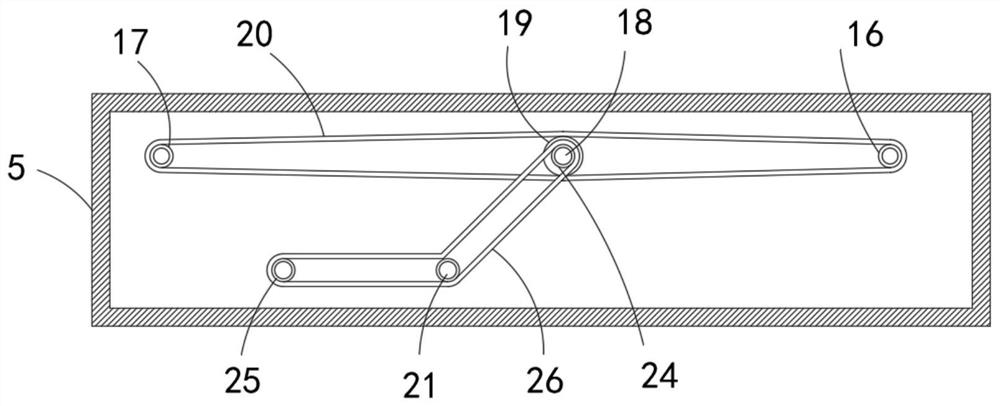

[0032] refer to Figure 1-8 , environmental protection, water treatment and automatic cutting conveyor for aquatic plants, including a cleaning boat 1, an L-shaped bracket 2 and a propeller 3, two L-shaped brackets 2 are symmetrically fixedly connected to the two side walls of the cleaning boat 1, and the L-shaped bracket 2 is far away from the cleaning boat The side wall of 1 is fixedly connected with an annular cover body, and the propeller 3 is correspondingly arranged in the annular cover body. A rectangular opening is provided on the side wall of the bow of the cleaning ship 1, and an arc-shaped material guide plate 4 is fixedly connected on the inner wall of the rectangular opening. And the arc-shaped material guide plate 4 is set downwards, and the inner wall of the cleaning ship 1 is fixedly connected with a horizontal first housing 5 and a second housing 6, and the first housing 5 and the second housing 6 are far away from the bottom of the cleaning ship 1. One end ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com