Production process of novel formaldehyde removal material

A production process, formaldehyde technology, applied in the field of air purification material production, can solve secondary pollution and other problems, achieve strong effect and long oxidation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

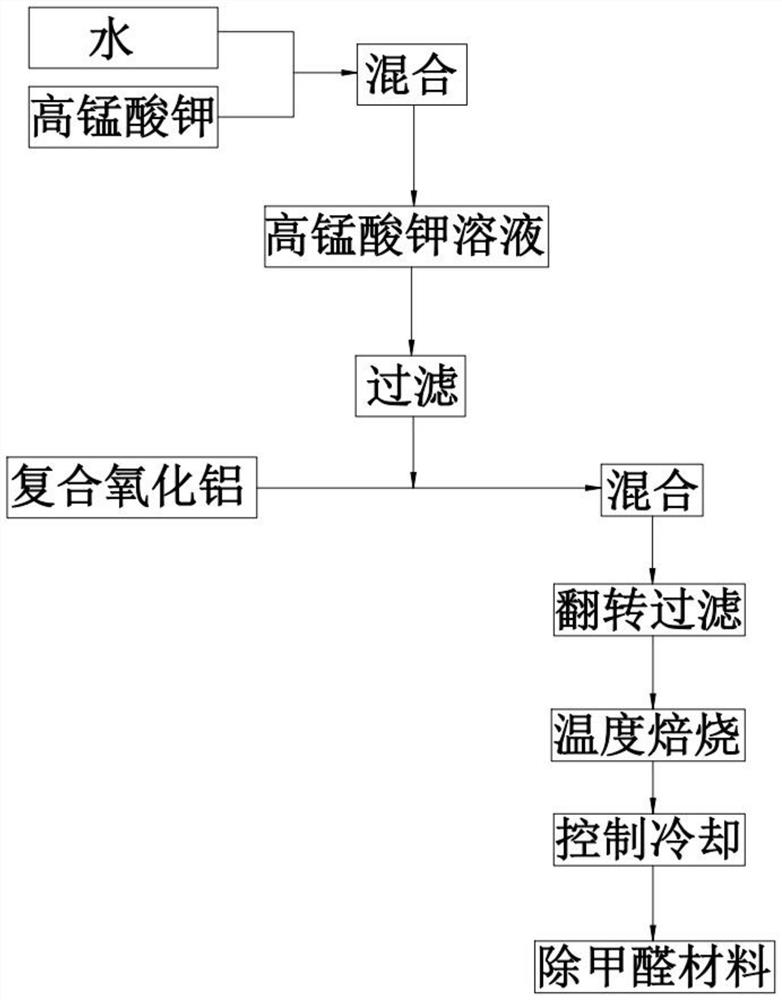

Image

Examples

Embodiment 1

[0024] A production process of a new type of formaldehyde-removing material, raw materials include water, potassium permanganate, and composite alumina, including the following steps:

[0025] Step 1: According to 26% of water, 5% of potassium permanganate, and 69% of composite alumina, the corresponding raw materials are weighed;

[0026] Step 2: Prepare potassium permanganate solution, mix and stir potassium permanganate and water in a container to obtain solution A, the water temperature is 80°C, and mix evenly;

[0027] Step 3: Filter the solution A obtained in step 2 through a multi-layer vibrating screen device to obtain solution B,

[0028] Step 4: Add composite alumina to the filtered solution B, stir for 30 minutes, and stir evenly;

[0029] Step 5: Filter the material in the mixed liquid in step 4, pour it into a temperature-controllable timing inversion container for inversion, control the temperature at 50°C and invert twice,

[0030] Step 6: temperature roasting...

Embodiment 2

[0033] A production process of a new type of formaldehyde-removing material, raw materials include water, potassium permanganate, and composite alumina, including the following steps:

[0034] Step 1: According to 20% of water, 4% of potassium permanganate, and 76% of composite alumina, the corresponding raw materials are weighed;

[0035] Step 2: Prepare potassium permanganate solution, mix and stir potassium permanganate and water in a container to obtain solution A, the water temperature is 80°C, and mix evenly;

[0036] Step 3: Filter the solution A obtained in step 2 through a multi-layer vibrating screen device to obtain solution B,

[0037] Step 4: Add composite alumina to the filtered solution B, stir for 50 minutes, and stir evenly;

[0038] Step 5: Filter the material in the mixed liquid in step 4, pour it into a temperature-controllable timed inversion container for inversion, control the temperature at 55°C and invert twice,

[0039] Step 6: temperature roasting,...

Embodiment 3

[0042] A production process of a new type of formaldehyde-removing material, raw materials include water, potassium permanganate, and composite alumina, including the following steps:

[0043] Step 1: According to 22% of water, 7% of potassium permanganate, and 71% of composite alumina, the corresponding raw materials are weighed;

[0044] Step 2: Prepare potassium permanganate solution, mix and stir potassium permanganate and water in a container to obtain solution A, the water temperature is 80°C, and mix evenly;

[0045] Step 3: Filter the solution A obtained in step 2 through a multi-layer vibrating screen device to obtain solution B,

[0046] Step 4: Add composite alumina to the filtered solution B, stir for 40 minutes, and stir evenly;

[0047] Step 5: Filter the material in the mixed liquid in step 4, pour it into a temperature-controllable timed inversion container for inversion, control the temperature at 55°C and invert twice,

[0048] Step 6: temperature roasting,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com