Preparation method of two-dimensional carbon nanosheet array loaded metal monatomic

A carbon nanosheet, metal-loaded technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poor stability and low atom utilization, and achieve Improve stability, solve the effect of low catalytic activity and active site utilization, and promote rapid transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

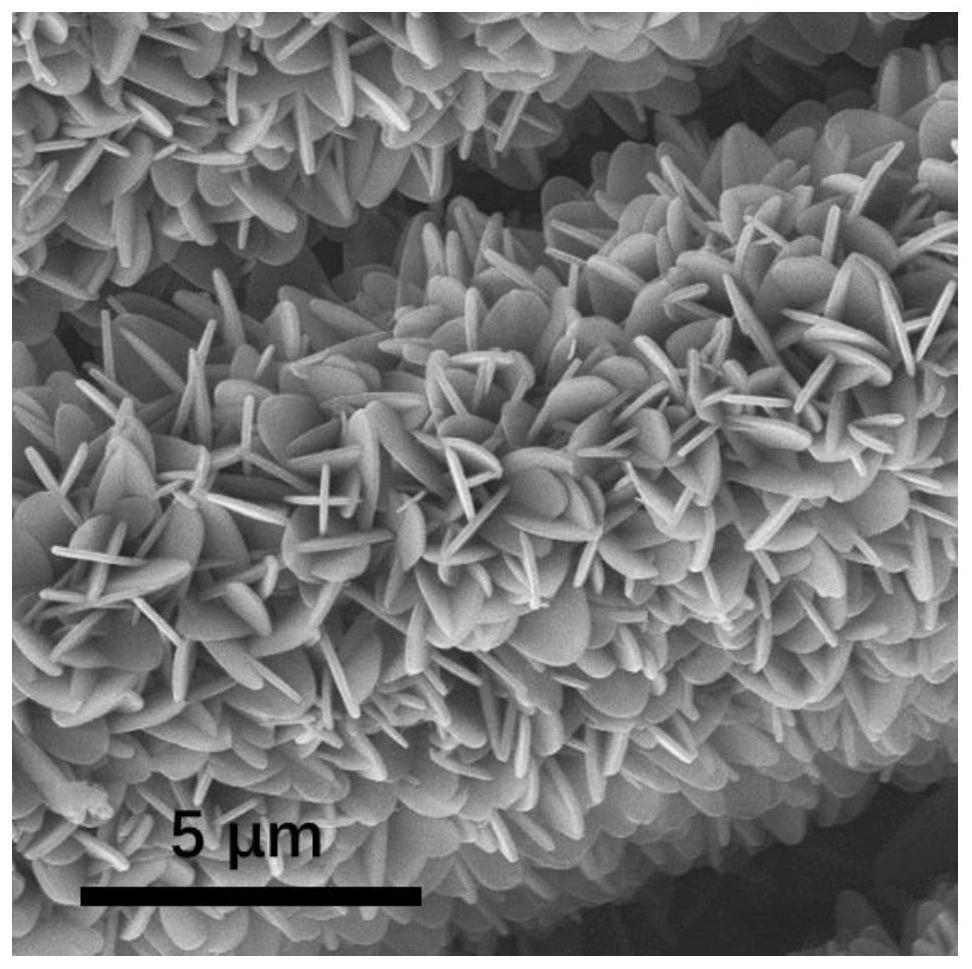

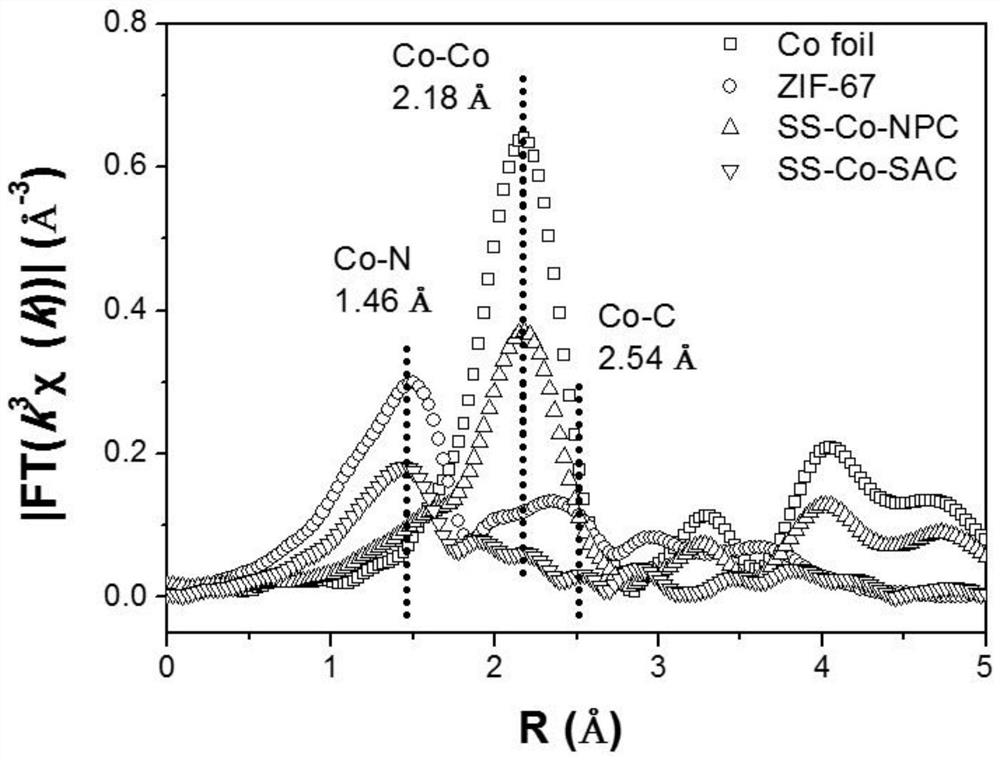

[0025] Two-dimensional carbon nanosheet arrays loaded with Co single atoms:

[0026] Using carbon cloth as a carrier, soak the carbon cloth in 0.5M potassium permanganate solution for 30 minutes. Preparation of reaction solution: A solution is 0.4M 2-methylimidazole aqueous solution, B solution is 0.05M zinc nitrate and cobalt nitrate aqueous solution (zinc-cobalt ratio is 4 / 1); mix A and B in a volume ratio of 1:1 liquid. The treated carbon cloth was immersed in the reaction solution and left to stand for 2 hours, then taken out and dried to obtain the ZnCo-MOF array precursor material. The prepared ZnCo-MOF array precursor material was fired in an atmosphere furnace with a nitrogen atmosphere, the firing temperature was 800 degrees Celsius, the heating rate was 2 degrees Celsius / min, and the firing time was 2 hours. The calcined material is taken out to support Co single atoms for the two-dimensional carbon nanosheet array.

[0027] Morphological characterization of ZnCo-...

Embodiment 2

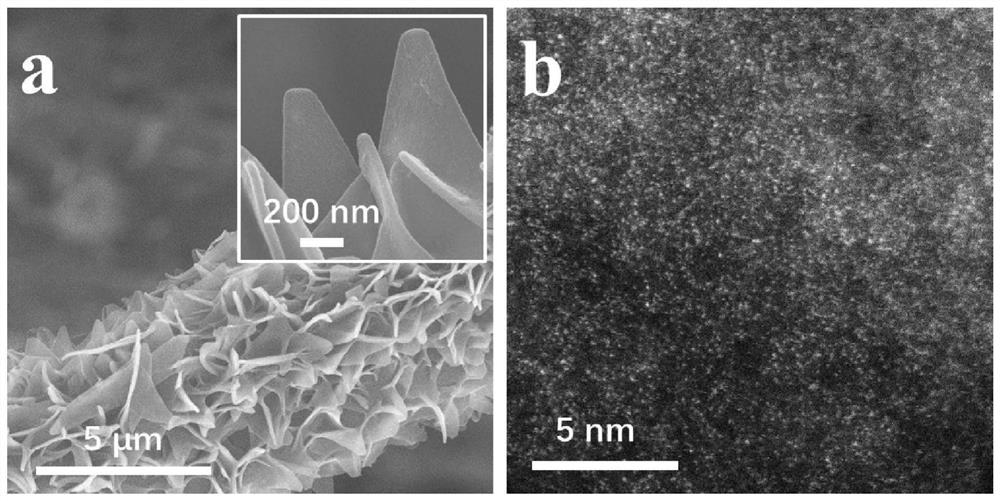

[0031] Two-dimensional carbon nanosheet arrays loaded with Co single atoms:

[0032] Using carbon cloth as a carrier, soak the carbon cloth in 0.5M potassium permanganate for 30 minutes. Preparation of reaction solution: liquid A is 0.4M 2-methylimidazole aqueous solution, liquid B is 0.05M cobalt nitrate aqueous solution; mix liquid A and liquid B at a volume ratio of 1:1. The treated carbon cloth was immersed in the reaction solution and left to stand for 1 hour, then taken out and dried to obtain the Co-MOF array precursor material. The prepared Co-MOF array precursor material was calcined in an atmosphere furnace with nitrogen atmosphere, the calcining temperature was 900°C, the heating rate was 5°C / min, and the calcining time was 1 hour. The calcined material was taken out and etched in 2M hydrochloric acid for 24 hours to obtain a two-dimensional carbon nanosheet array supporting Co single atoms.

[0033] Morphological characterization of Co single-atom materials suppo...

Embodiment 3

[0035] Two-dimensional carbon nanosheet arrays loaded with Fe single atoms:

[0036] Using carbon cloth as a carrier, soak the carbon cloth in 0.5M potassium permanganate for 30 minutes. Preparation of reaction solution: A solution is 0.4M 2-methylimidazole aqueous solution, B solution is 0.05M zinc nitrate and ferric nitrate aqueous solution (the ratio of zinc to iron is 10 / 1); mix A and B at a volume ratio of 1:1 liquid. The treated carbon cloth was immersed in the reaction solution and left to stand for 2 hours, then taken out and dried to obtain the ZnFe-MOF array precursor material. The prepared ZnFe-MOF array precursor material was calcined in an atmosphere furnace with nitrogen atmosphere, the calcining temperature was 800 degrees Celsius, the heating rate was 2 degrees Celsius / min, and the calcining time was 2 hours. The calcined material is taken out to support Fe single atoms for the two-dimensional carbon nanosheet array.

[0037]Morphological characterization of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com