Feed preparation method

A feed and raw material technology, applied in the direction of feed, food processing, grain processing, etc., can solve the problems of the impact of the next screening, containing soil, reducing the quality of feed, etc., to achieve the effect of ensuring cleanliness, ensuring uniformity, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

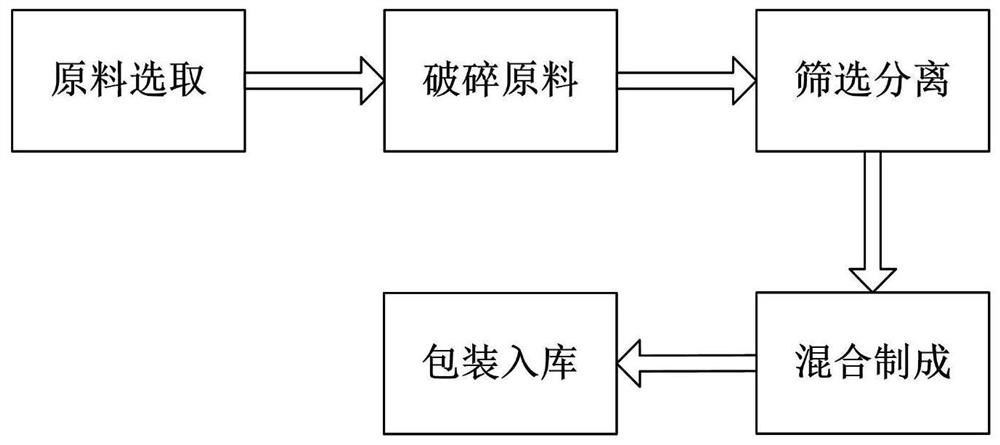

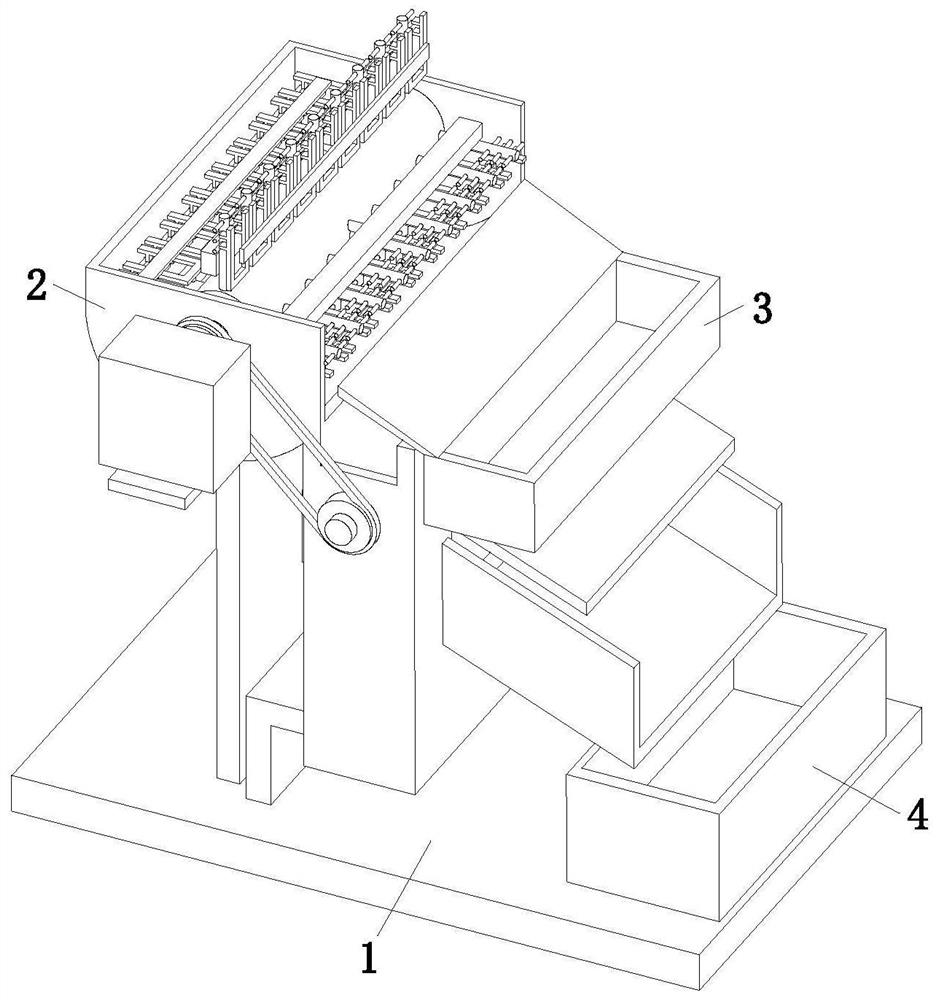

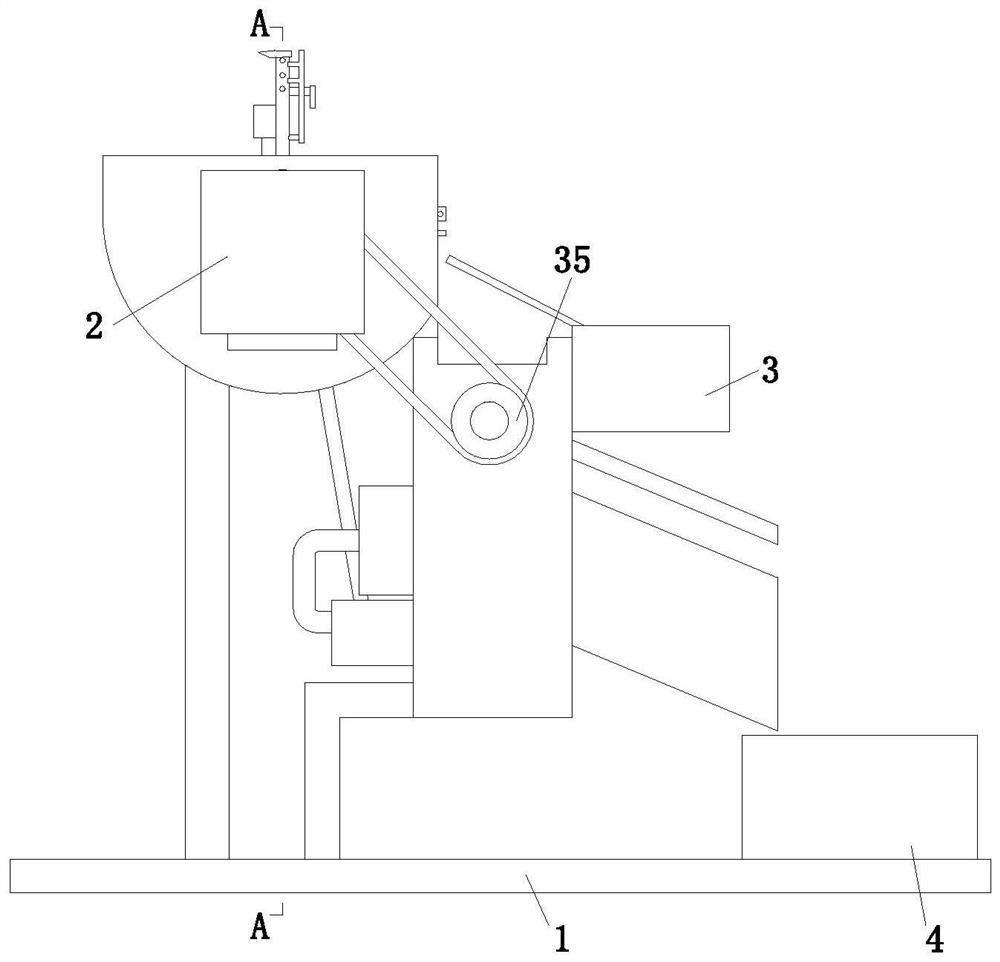

[0035] like Figure 1 to Figure 8 As shown, in order to achieve the above object, the present invention adopts the following technical solutions, a feed preparation method, which uses a feed preparation equipment, the feed preparation equipment includes a base plate 1, a screening device 2, a separation device 3 and a collection frame 4, The specific method of screening and separating the crushed feed raw materials with feed preparation equipment is as follows:

[0036] S1. Raw material selection: Manually select the raw materials to make the required feed, and transport the raw materials to the crushing place;

[0037] S2. Crushing raw materials: manually put the raw materials into the crusher, and the crusher crushes the raw materials;

[0038] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com