A method for anti-condensation in the process of reusing dry calcium carbide slag

A carbide slag and anti-condensation technology, which is applied in separation methods, chemical instruments and methods, and solid waste removal, etc. The problem of high cost, to achieve the effect of improving moisture absorption and condensation performance, reducing equipment maintenance frequency, good economic and social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

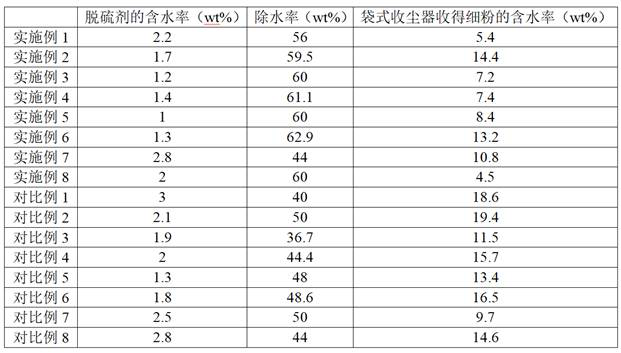

Examples

Embodiment 1

[0035]This example provides a method for anti-condensation during the reutilization of dry calcium carbide slag. The method includes adding a dehumidifier in the impurity removal process of preparing the desulfurizer, wherein the desulfurizer is prepared by winnowing, and the dehumidifier is 90wt % calcium oxide and 10wt% anhydrous calcium sulfate, mixed dry carbide slag and desiccant in the raw material storage device, wherein the moisture content of the dry carbide slag is 5wt%, and the particle size of the dry carbide slag is less than 100 microns The particle content is 85wt%, and the content of particles with a particle size <50 microns in the dry process carbide slag is 50 wt%, the mass ratio of the desiccant to the dry process carbide slag is 0.05:1, and the particles with a particle size <50 microns in the desiccant The content of particles is 95wt%; and the content of particles with a particle diameter of <20 microns in the desiccant is 55wt%.

Embodiment 2

[0037] This example provides a method for anti-condensation during the reutilization of dry calcium carbide slag. The method includes adding a dehumidifier in the impurity removal process of preparing the desulfurizer, wherein the desulfurizer is prepared by winnowing, and the dehumidifier is 15wt % calcium oxide, 70wt% anhydrous calcium sulfate, 10wt% magnesium sulfate and 5wt% sodium sulfate, mixed dry carbide slag and desiccant at the feed inlet, wherein the moisture content of dry carbide slag is 4.2wt %, the particle content of particle diameter<100 microns in the dry process carbide slag is 90wt%, and the particle content of particle diameter<50 microns in the dry process carbide slag is 45wt%, and the mass ratio of desiccant and dry process carbide slag is 0.02: 1. The content of particles with a particle size <50 microns in the desiccant is 85 wt%, and the content of particles with a particle size <20 microns in the desiccant is 45 wt%.

Embodiment 3

[0039] This example provides a method for anti-condensation during the reutilization of dry calcium carbide slag. The method includes adding a dehumidifier in the impurity removal process of preparing the desulfurizer, wherein the desulfurizer is prepared by winnowing, and the dehumidifier is 85wt % of calcium oxide, 10wt% of anhydrous calcium sulfate and 5wt% of sodium hydroxide, mixed dry carbide slag and desiccant in the delivery pipeline, wherein the moisture content of dry carbide slag is 3wt%, in dry carbide slag The content of particles with a particle size of <100 microns is 75wt%, and the content of particles with a particle size of <50 microns in the dry-process carbide slag is 33wt%, and the mass ratio of the desiccant to the dry-process carbide slag is 0.007:1. In the desiccant The content of particles with a particle diameter of <50 microns is 90 wt%, and the content of particles with a particle diameter of <20 microns in the desiccant is 40 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com