Intelligent furfural residue conveying system

A conveying system and furfural slag technology, used in conveyors, transportation and packaging, drying of solid materials, etc., can solve the problems of inconvenient rotation and steering, easy to affect conveying, inconvenient adjustment, etc., and achieve the effect of increasing drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

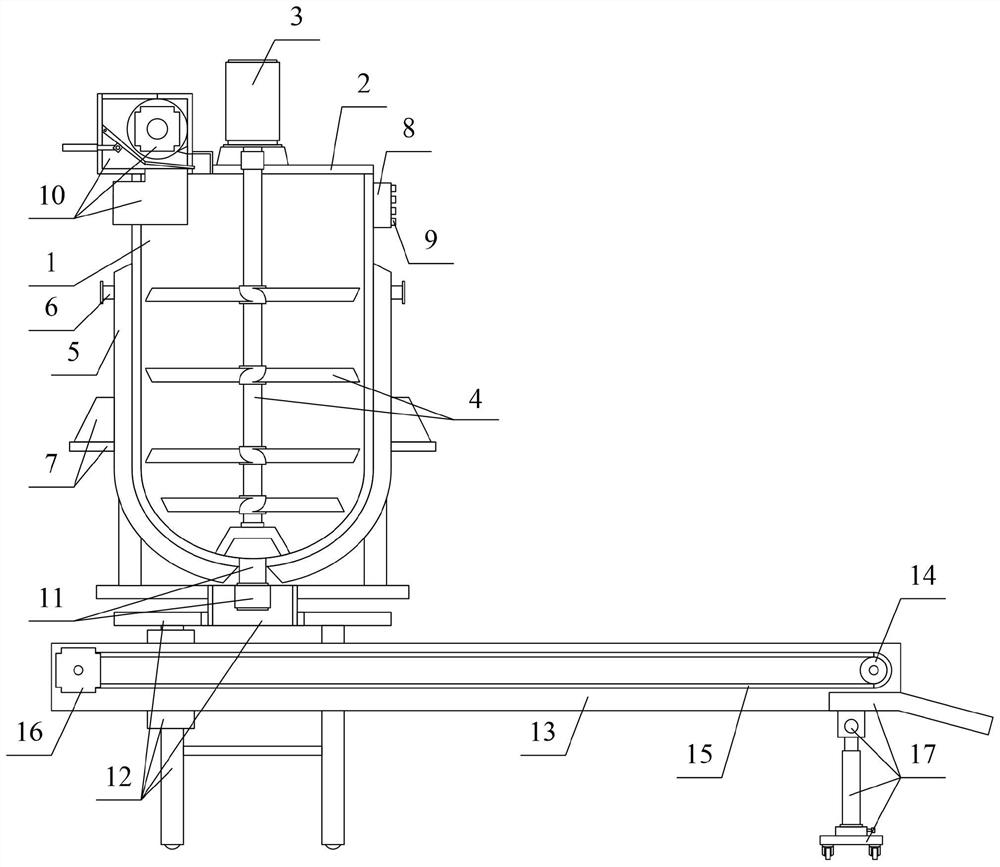

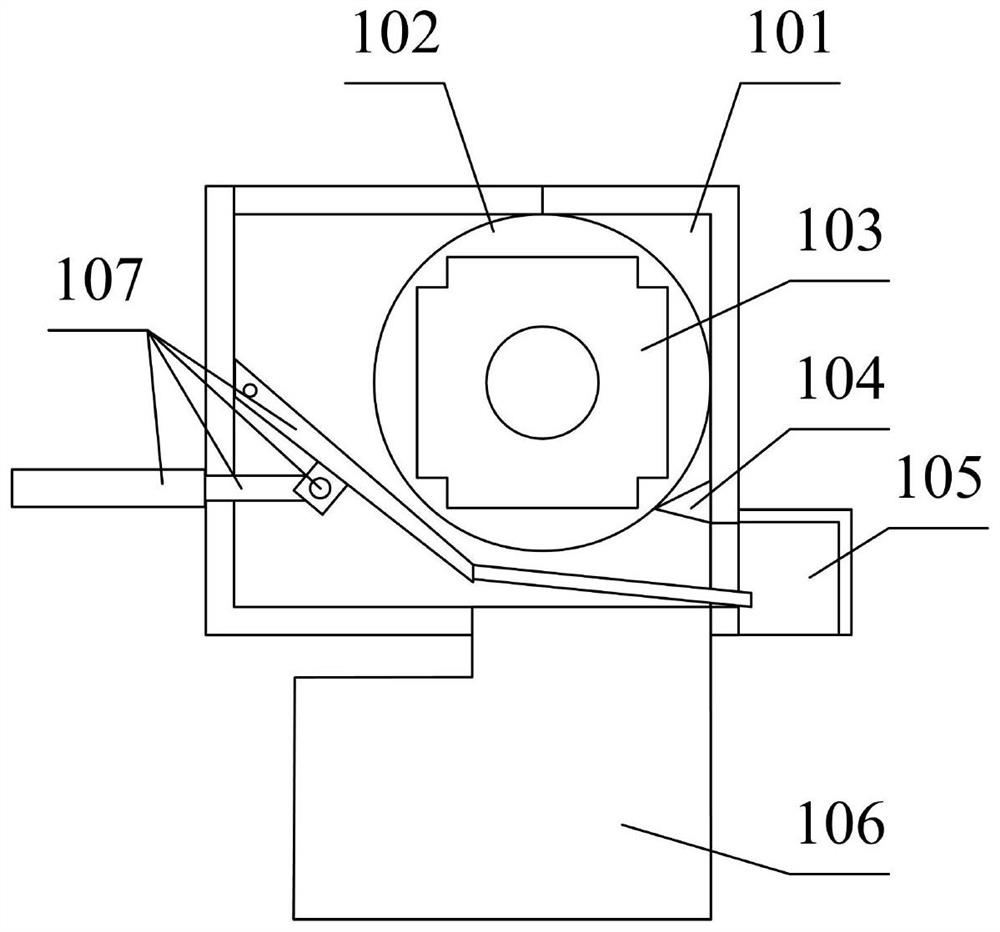

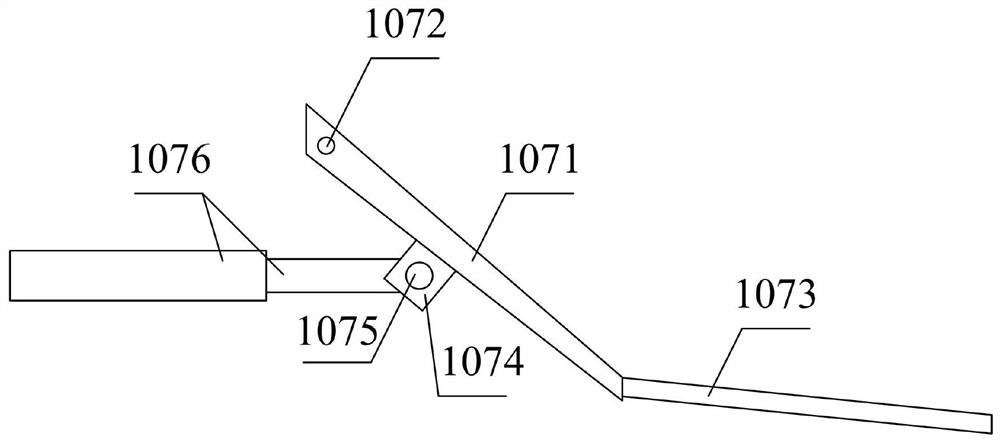

[0039] as attached figure 1 to attach figure 2As shown, the intelligent furfural slag conveying system includes a mixing bin 1, a supporting plate 2, a stirring motor 3, a stirring frame 4, a heating shell 5, a steam inlet pipe 6, a supporting ear plate 7, a controller 8, a drive switch 9, Auxiliary squeeze tank structure 10, discharge valve 11, rotatable support frame structure 12, support plate 13, rotating drum 14, conveyor belt 15, conveying motor 16 and adjustable support frame structure 17, the support plate 2 is welded on the stirring The right side of the upper end of the warehouse 1; the bolts of the stirring motor 3 are installed on the left side of the upper end of the support plate 2; the upper end of the stirring frame 4 is connected with the output shaft coupling of the stirring motor 3; the heating shell 5 is welded In the lower part of the outer wall of the mixing chamber 1; the steam inlet pipes 6 are respectively welded on the upper parts of the left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com