Anti-crack freezing well wall concrete and preparation method thereof

A technology for concrete and freezing wells, which is applied in the field of crack-resistant freezing well wall concrete and its preparation, and can solve problems such as large early temperature stress and large temperature difference between inner and outer walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

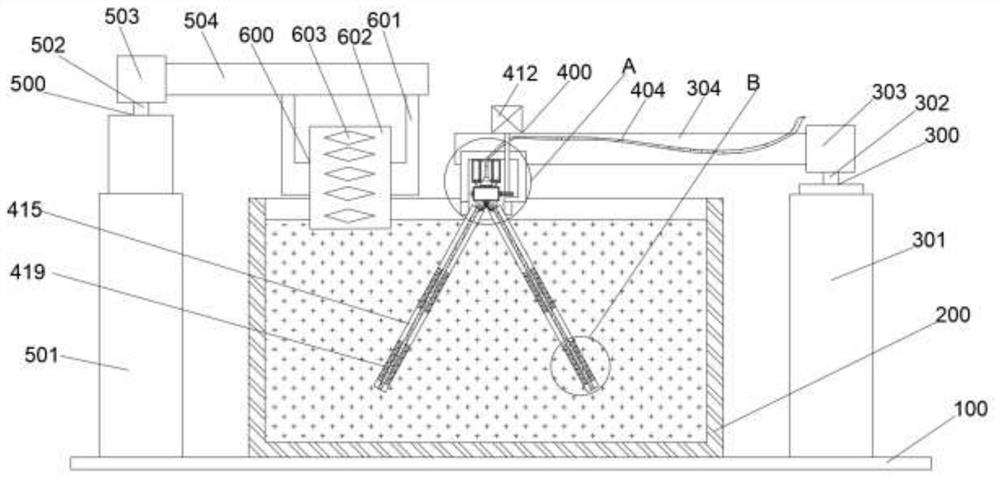

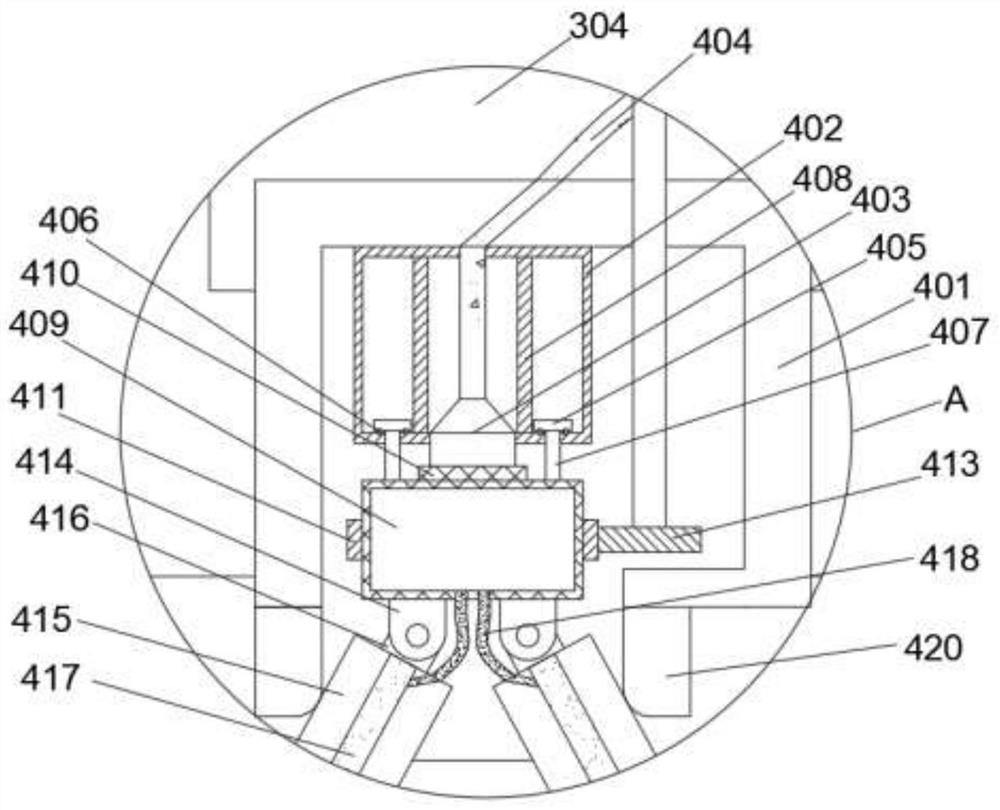

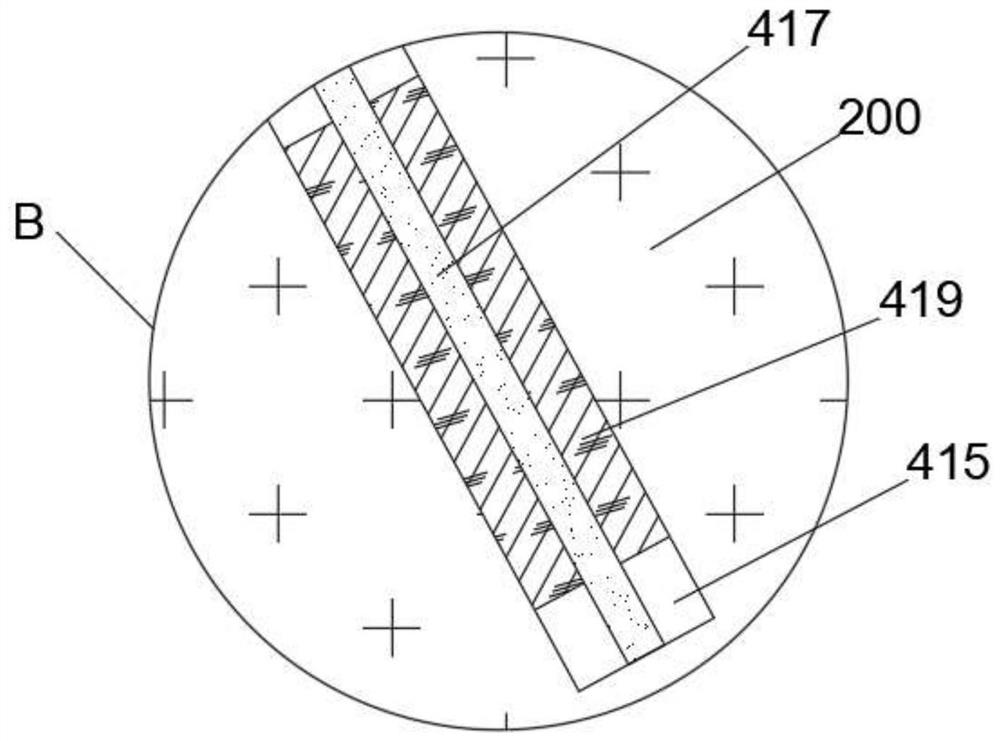

Image

Examples

Embodiment 1

[0054] 1. Test raw materials

[0055] 1. Cement

[0056] Ordinary Portland cement with P O 52.5 is used, and the main performance indicators are shown in Table 1.

[0057] Table 1 Main performance indicators of cement

[0058]

[0059] 2. Aggregate

[0060] Limestone crushed stone is used as the coarse aggregate, the crushing index is 4.9%, and the mud content is about 0.4%. Large stones (10mm ~ 20mm continuous gradation), small stones (5mm ~ 10mm continuous gradation). The fine aggregate adopts standard sand with a fineness modulus of 2.6 and a mud content of about 0.4%, which belongs to medium sand.

[0061] 3. Fly ash

[0062] Grade I fly ash in Beijing area is used, and its performance indicators are shown in Table 2.

[0063] Table 2 Main performance indicators of fly ash

[0064]

[0065] 4. Admixture

[0066] The polycarboxylate high-efficiency water reducer produced by Beijing Tongke Building Materials Co., Ltd. is used, and the water reduction rate is 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com