Cooling, vacuum sealing and insulating device suitable for semiconductor processing degumming process

A technology of vacuum sealing and insulating devices, which is applied in household refrigeration devices, cooling fluid circulation devices, semiconductor/solid-state device manufacturing, etc. It can solve problems such as insufficient cooling, risky insulation, and damage to component connections to achieve cooling and cooling effects Good, reduce welding, increase the effect of the loop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

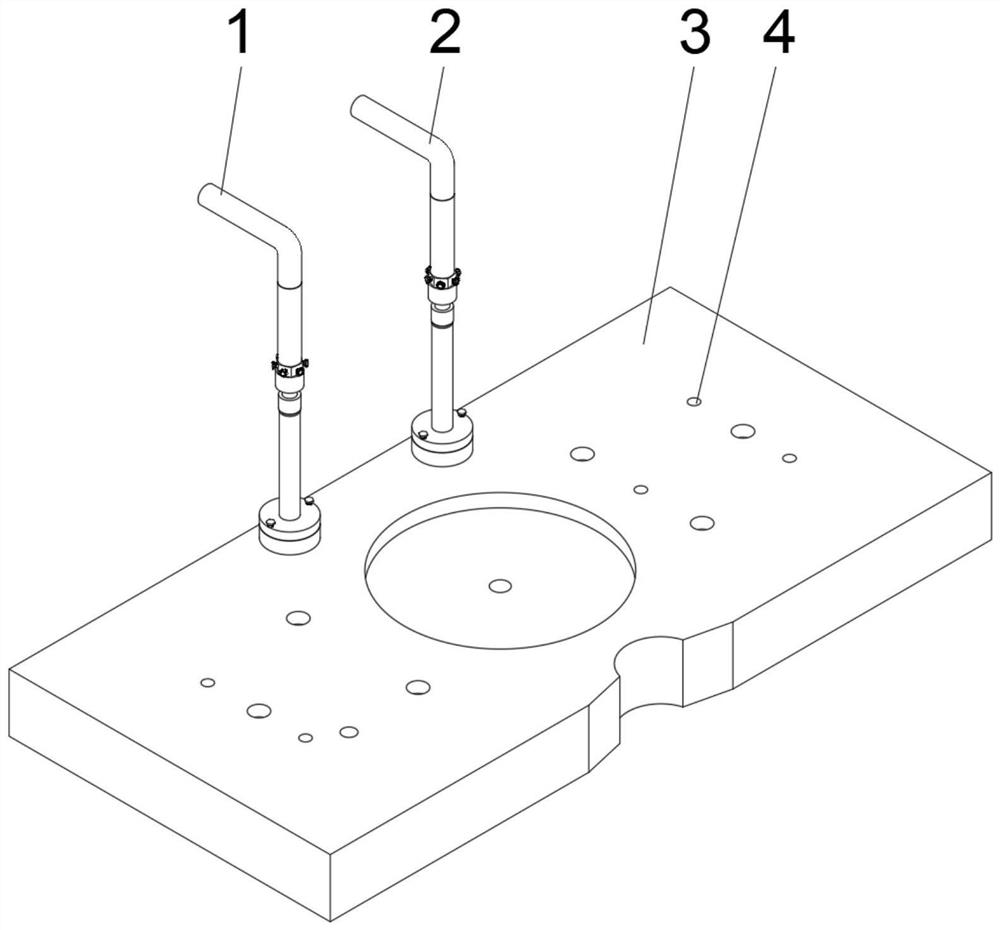

[0041] see figure 1 , an embodiment provided by the present invention: a cooling, vacuum sealing and insulating device suitable for semiconductor processing degumming process, including a first cooling mechanism 1, a second cooling mechanism 2, a cooling block main body 3 and a threaded fixing hole 4. The first cooling mechanism 1 and the second cooling mechanism 2 are screwed and fixedly installed on the upper end of one side of the cooling block main body 3, and the screw fixing installation holes 4 are evenly opened at both ends of the cooling block main body 3, and the first cooling mechanism 1 and the The structural specifications of the second cooling mechanism 2 are the same;

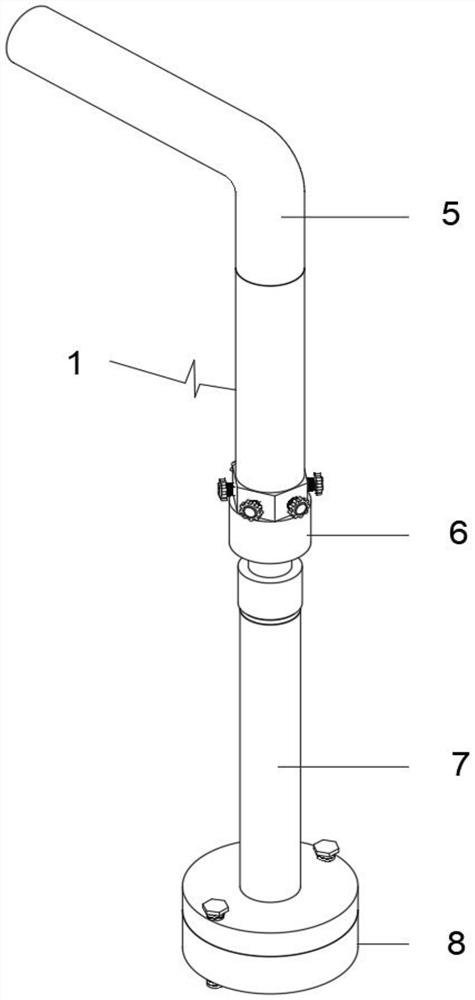

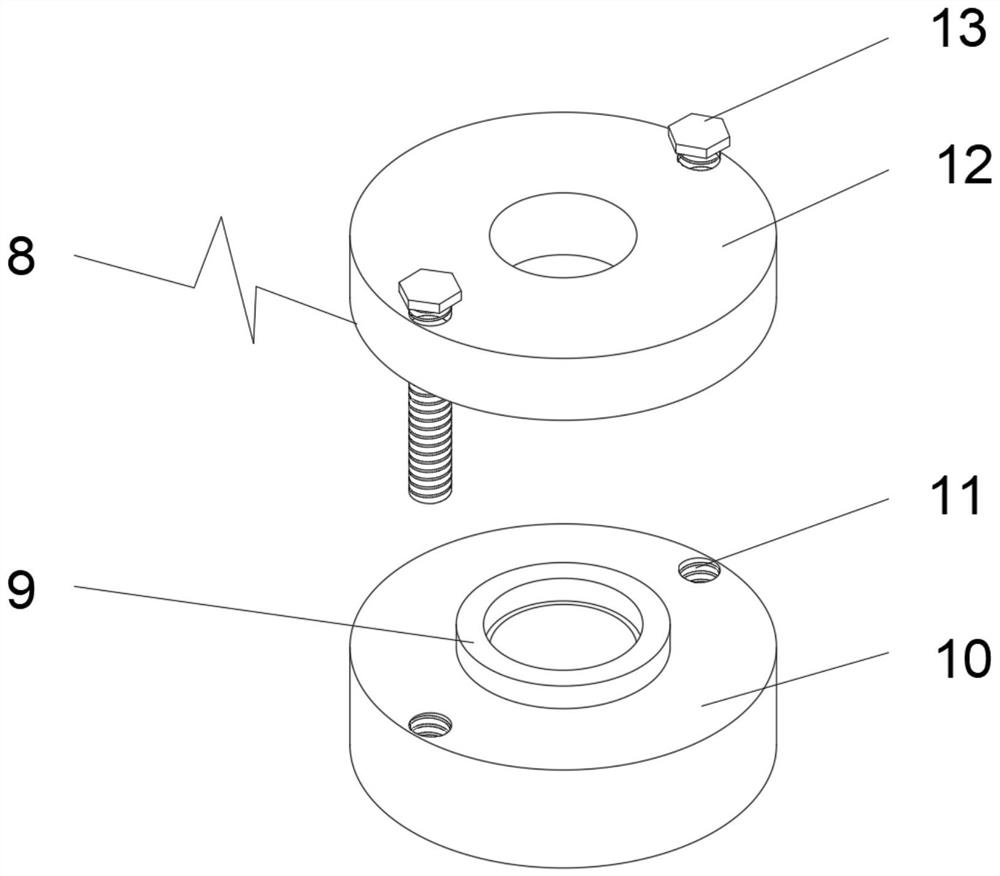

[0042] see figure 2 and Figure 7 , the first cooling mechanism 1 includes an insulating pipe 5, a first connecting sealing device 6, a connecting pipe 7 and a second connecting sealing device 8, and the connecting pipe 7 is fixedly installed between the first connecting sealing device 6 and t...

Embodiment 2

[0049] On the basis of Example 1, such as Figure 9-10 As shown, the upper end of the fastening threaded column 13 is fixedly equipped with a screw handle 28, the middle part of the screw handle 28 is a metal block, the outside of the metal block is wrapped with a rubber sleeve, and the inside of the sealing socket 16 is fixedly embedded with a non-slip seal ring. 29. The anti-skid sealing ring 29 is made of rubber.

[0050] When implementing this embodiment, the upper end of the fastening threaded post 13 is fixedly installed with a screw handle 28, and the middle part is a metal block, and the outside of the metal block is wrapped with a rubber sleeve, so as to facilitate the installation of the first step insulating flange 12. Screwing, if there is no basis, the first cooling mechanism 1, the second cooling mechanism 2 and the cooling block main body 3 can be quickly fixed and fast fixedly connected, and the inside of the sealing insertion groove 16 is fixedly embedded with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com